Method for preparing a microgap sleeve optical fiber prefabrication bar and method for drawing and preparing an optical fiber by microgap sleeve optical fiber prefabrication bar

An optical fiber preform and micro-gap technology, which is used in glass manufacturing equipment, glass fiber drawing devices, manufacturing tools, etc. The geometric parameters are stable, the shrinkage effect is good, and the strength is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

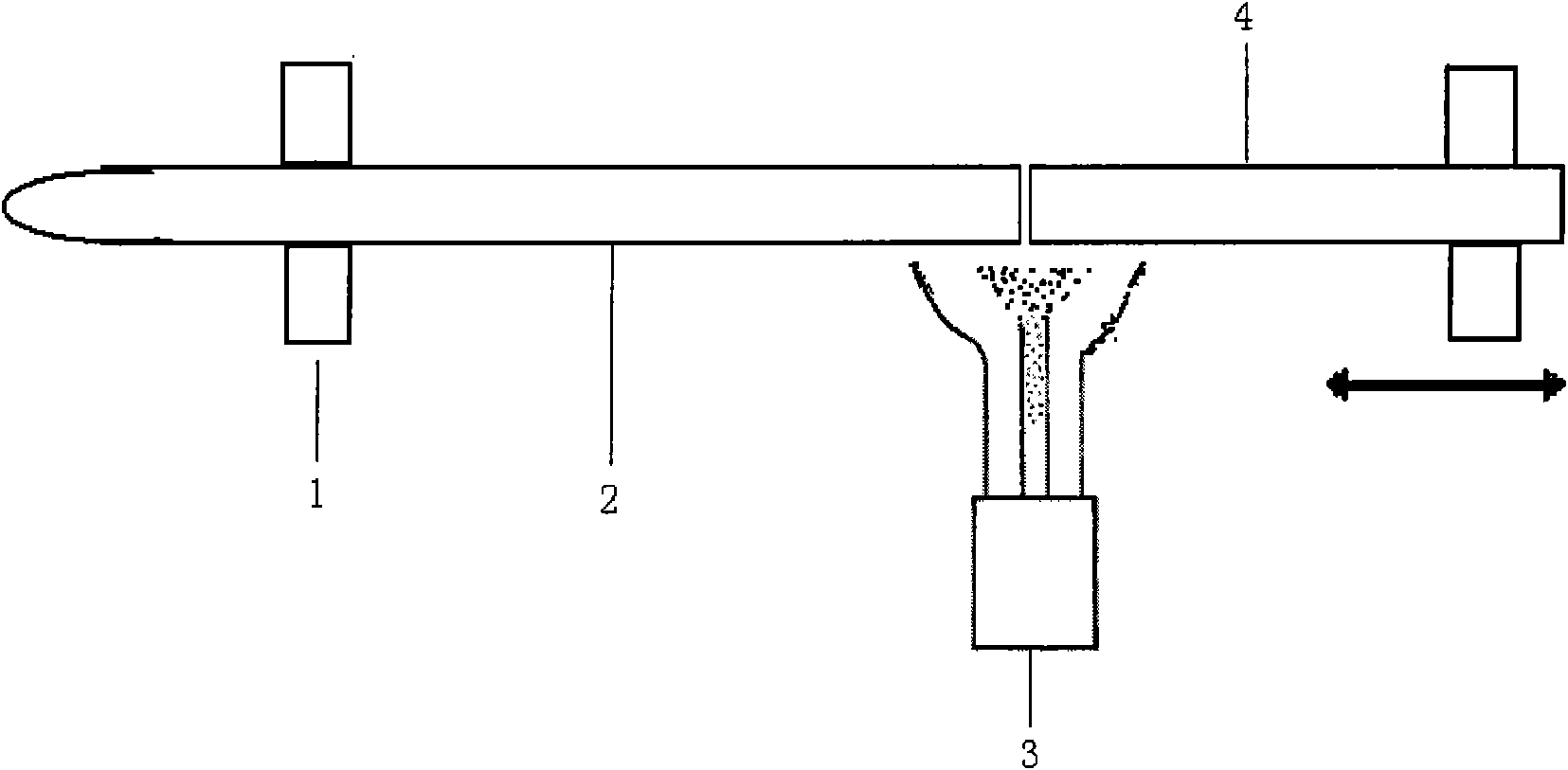

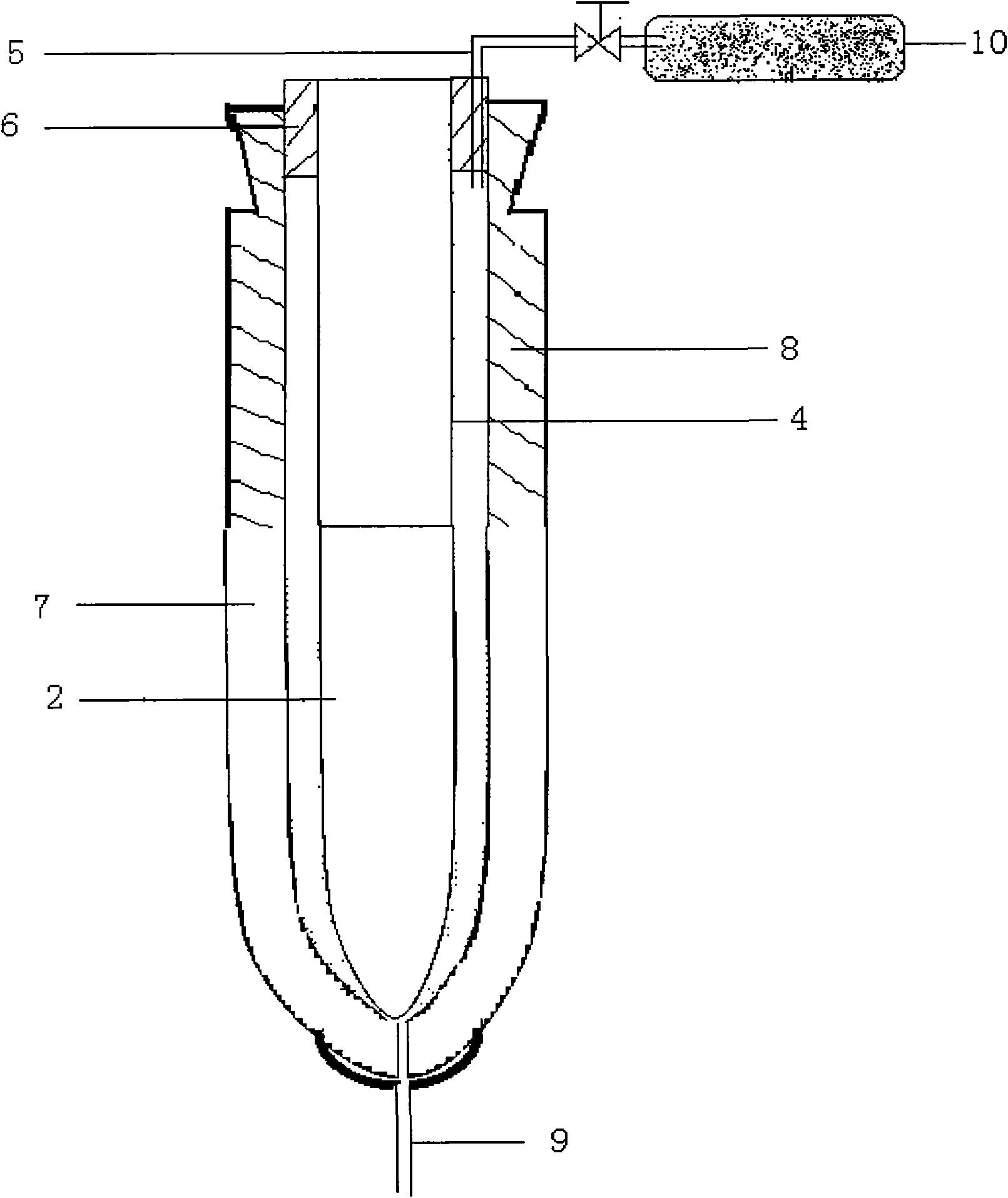

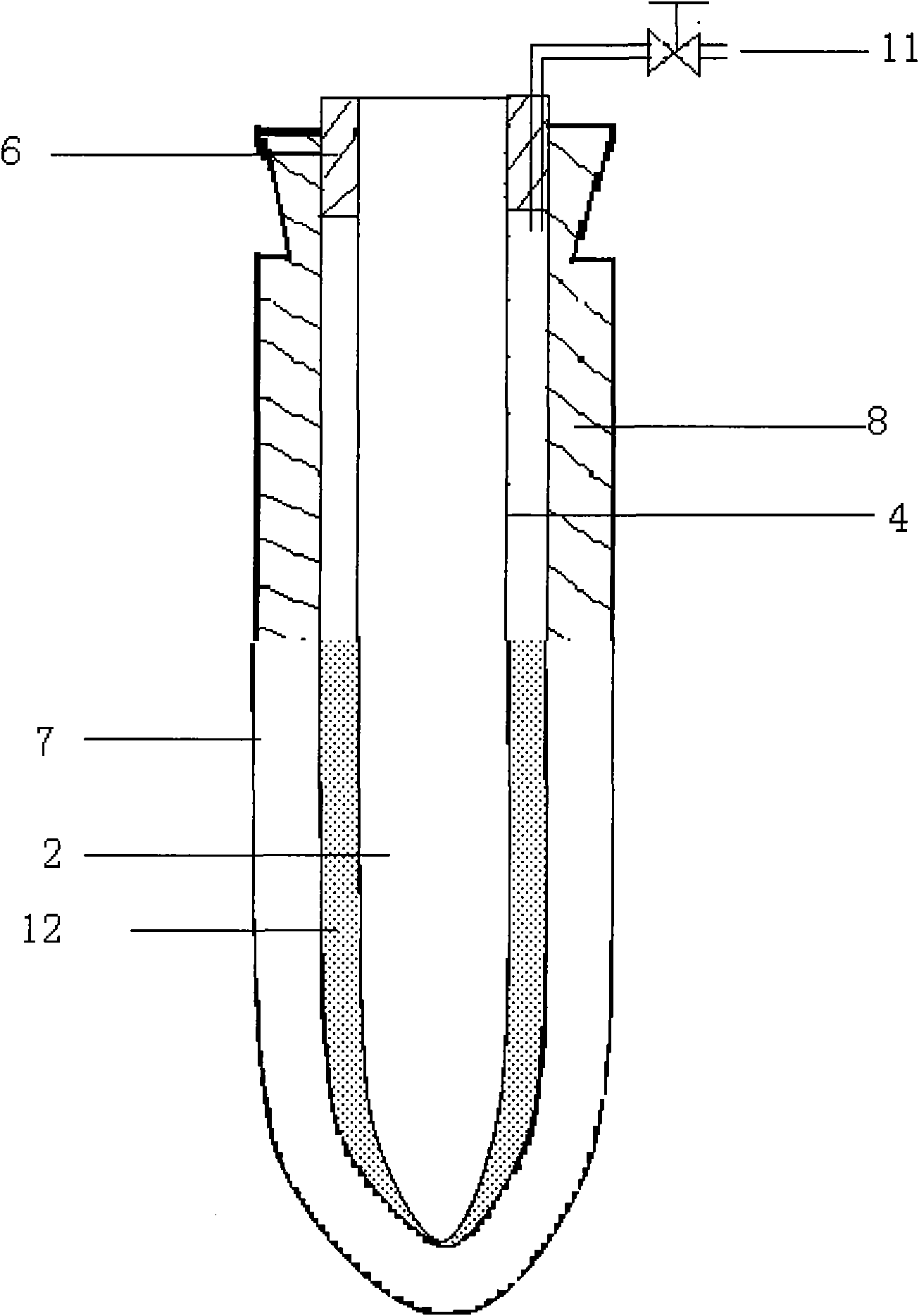

[0040] Refer to attached Figure 1~3 , preparation method of micro-gap sleeve optical fiber preform and method for drawing optical fiber thereof

[0041] The preparation method of the micro-gap sleeve optical fiber preform is as follows:

[0042] 1) handle

[0043] Using a glass lathe and using the hydrogen-oxygen flame of the blowtorch 3, the end faces of the mandrel 2 and the handle 4, the casing 7 and the tail handle 8 are melted at a high temperature of 1600 ° C to 1900 ° C, respectively, and then butt jointed, which is the joint handle. This process is performed in BC700- 250 double-chuck 1 glass lathe, the overall bow of the whole mandrel 2 and handle 4, sleeve 7 and tail handle 8 are controlled within 0-0.1mm / m after the handle is connected.

[0044] 2) Wash and dry

[0045] After the connection is completed, the surface of the mandrel 2 and the casing 7 needs to be cleaned for 2 hours with hydrofluoric acid with a concentration of 2% to 3% to remove surface pollutan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com