Medium-temperature color glaze formula and sintering process thereof

A color glaze and formula technology, applied in the field of ceramic color glaze, can solve the problems of inconvenient acquisition of raw materials, large expansion system, small melting range, etc., and achieve the effects of improving glaze layer and mechanical properties, reducing firing temperature, and wide melting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one: a kind of medium temperature color glaze formula, the basic glaze of this formula contains the raw material of following weight percentage:

[0019] Potassium and sodium composite feldspar 35-45%, kaolin 6-8%, quartz 13-18%, limestone 10-15%, talc 0-8%, zinc oxide 0-6%, barium carbonate 0-6%, ZrSiO4 5 -10%, Sericite 1-3%.

[0020] A successful glaze formula is not simply a reasonable combination of several raw materials. It is restricted and restricted by various conditions, such as raw material origin, material, body shape, performance, kiln structure, atmosphere, Firing temperature, curve, etc., focusing on the combination of glaze, glaze layer maturation temperature, coloring effect and glaze quality. In order to ensure the medium-temperature firing performance of the glaze water and prevent the appearance of color difference changes, the present invention selects potassium-sodium composite feldspar with a potassium-sodium ratio of 1:1 to replace the...

Embodiment 2

[0032] Embodiment two: a kind of medium temperature color glaze formula, the basic glaze of this formula contains the raw material of following weight percentage:

[0033] Potassium sodium composite feldspar 39%, kaolin 7%, quartz 16%, limestone 12%, talc 4%, zinc oxide 2%, barium carbonate 4%, ZrSiO4 8%, sericite 2%.

[0034] The colored glaze of this formula contains the raw material of following weight percentage:

[0035] Cobalt oxide 3%, Iron oxide 2%, Chromium oxide 1%.

Embodiment 3

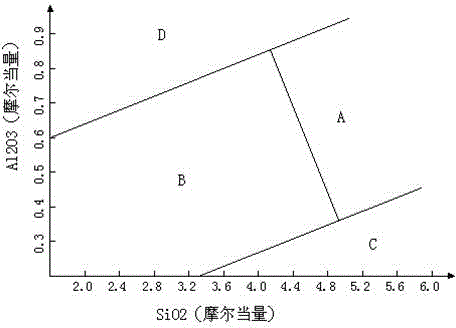

[0036] Embodiment 3: The glaze formula of this color glaze is 0.30 KNaO, 0.25 CaO, 0.0406 MgO, 0.20 ZnO, 0.05 MgO, 0.40 Al2O3, 3.5 SiO2.

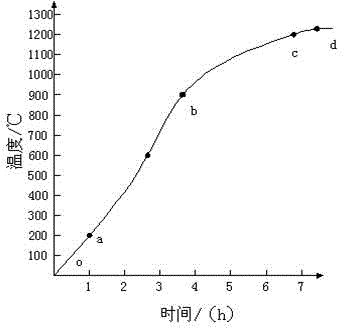

[0037] The firing process of the color glaze comprises the following steps:

[0038] 1. Green body selection: The quality of the glaze directly depends on the adaptability to the green body. To achieve the best glaze quality, you must choose a suitable green body. For the glaze, the weakly acidic body is matched with the alkaline glaze, the feldspar glaze chooses the body with high silicon content, and the lime glaze is matched with the body with high aluminum content;

[0039] 2. Preparation of glaze: The glaze quality of ceramic products is the key to determine the quality of its products. The key to determining the quality of the glaze lies in the scientificity and rationality of the glaze formula. The glaze formula of the present invention is as described above, and the glaze is prepared according to the formula of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com