A kind of preparation method of blue gradient glaze sanitary ceramics

A sanitary ceramics, blue technology, applied in the field of sanitary ceramics, can solve the problems of difficult, difficult glaze preparation methods, restrictions on the diversification of ceramic products and personalized development, etc., to achieve good coherence, stable and pure color development, Avoid the effect of uneven surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

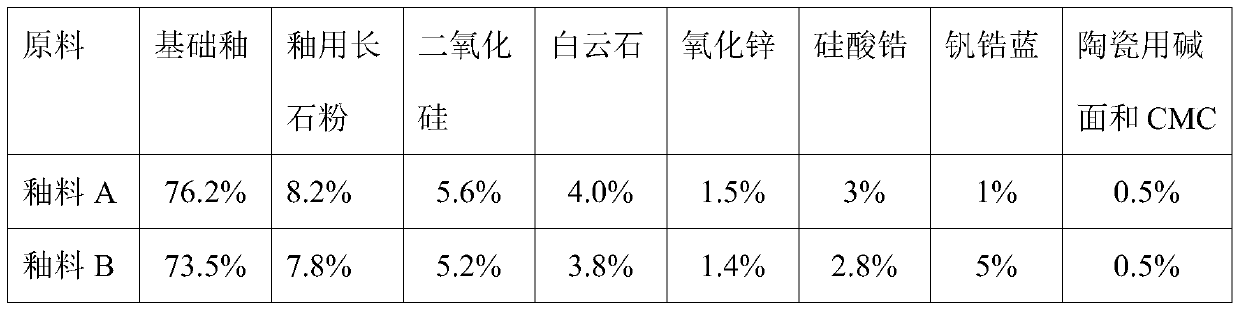

Embodiment 1

[0031]

[0032] (1) According to the formula table of glaze material A and glaze material B mentioned above, put them into the ceramic ball mill and carry out ball milling with water as the medium (first add basic glaze, silicon dioxide, dolomite, zinc oxide, zirconium silicate, long For stone powder and ceramic alkali surface and CMC, when the particle size reaches ≤10μm and accounts for 63%, then add vanadium-zirconium blue material, and continue ball milling until the particle size reaches ≤10μm and account for 72%, the ball milling ends), and glaze slurry A and Glaze slurry B; the formula of the basic glaze is: 36.49% feldspar powder for glaze, 24.19% silicon dioxide, 28.59% calcite, 4.26% zinc oxide and 6.47% aluminum oxide powder, plus the sum of the above components 1.5 % 807 frit powder.

[0033] (2) Refining the above-mentioned glaze slurry A and glaze slurry B, the first step is to sieve the glaze slurry, and the glaze slurry needs to be filtered through a 180 mes...

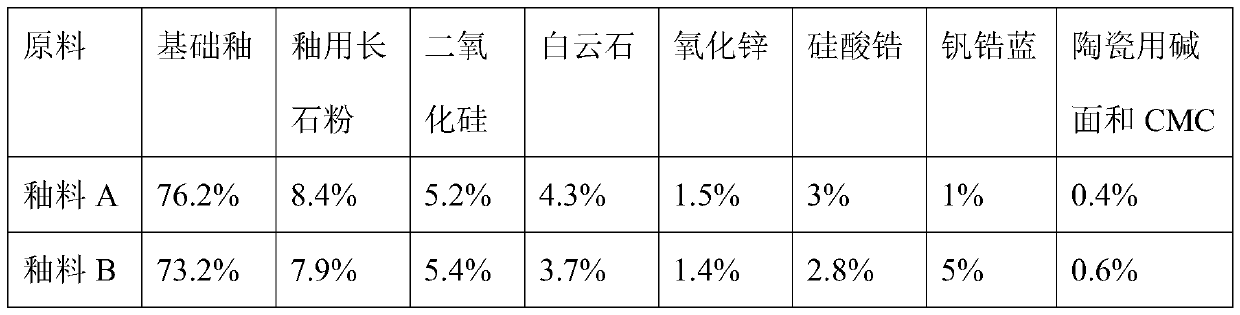

Embodiment 2

[0043]

[0044] (1) According to the formula table of glaze material A and glaze material B mentioned above, put them into the ceramic ball mill and carry out ball milling with water as the medium (first add basic glaze, silicon dioxide, dolomite, zinc oxide, zirconium silicate, long For stone powder and ceramic alkali surface and CMC, when the particle size reaches ≤10μm and accounts for 63.5%, add vanadium-zirconium blue material, and continue ball milling until the particle size reaches ≤10μm, accounting for 72.1%. Slurry B; Wherein basic glaze formula is the same as embodiment 1.

[0045] (2) Refining the above-mentioned glaze slurry A and glaze slurry B, the first step is to sieve the glaze slurry, and the glaze slurry needs to be filtered through a 180 mesh screen; the second step is to adjust the glaze content contained in the glaze slurry. water to ensure its reasonable physical properties; the third step is to use iron removal rods (or iron removers) for sanitary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com