Residual oil hydrogenation protective agent carrier, catalyst and preparation method thereof

A technology for residual oil hydrogenation and protective agent, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., and can solve problems such as low asphaltene conversion ability, poor pore connectivity, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Take by weighing 27.5 grams of activated carbon with a particle diameter of 8 microns, impregnate the activated carbon with equal volumes of the ammonium metavanadate aqueous solution containing 0.25 gram of ammonium metavanadate, the activated carbon after the impregnation and 145 grams of pseudoboehmite, 2 gram of turmeric powder, Mix 0.91 g of ammonium heptamolybdate evenly, add an appropriate amount of acetic acid aqueous solution with a mass concentration of 1.5%, mix and knead, extrude the molded product, dry the molded product at 100 ° C for 6 hours, and roast the dried product at 700 ° C for 5 hours in an air atmosphere to obtain intermediate body.

[0051] Weigh 100 grams of the above-mentioned intermediate, place it in 800 grams of ammonium bicarbonate solution, the mass concentration of the ammonium bicarbonate solution is in an aqueous solution of 19.5%, transfer the mixed material into an autoclave and seal it at a speed of 15°C / min After raising the temper...

Embodiment 2

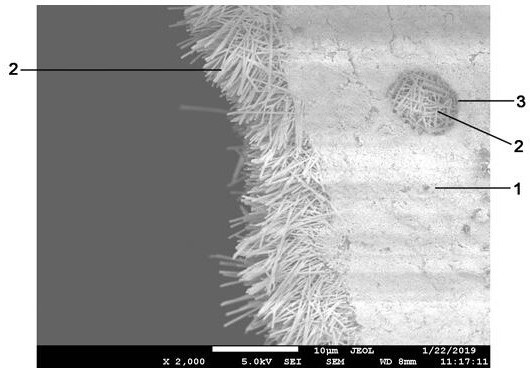

[0054] With embodiment 1, just gac is changed into the charcoal that particle diameter is 10 microns, and add-on is 22.5 grams, and ammonium metavanadate add-on is 0.4 gram, and ammonium heptamolybdate add-on is 0.62 gram. The quality of ammonium bicarbonate solution is 700 grams, and the mass concentration of ammonium bicarbonate solution is 22.5%. The sealing pretreatment temperature is 90° C., the treatment time is 2 hours, the heat treatment temperature is 135° C., and the treatment time is 7 hours, and the residual oil hydrogenation protection agent carrier A2 is prepared. The properties of the carrier are shown in Table 1. Among them, the length of the rod-shaped modified alumina in the micron-scale pores of the carrier is mainly 3.0-8.0 μm, the length of the rod-shaped modified alumina on the outer surface of the main modified alumina is mainly 3-8 μm, and the rod-shaped modified alumina is mainly 3-8 μm. The diameter is about 100-280nm, the coverage rate of rod-shaped...

Embodiment 3

[0057] With embodiment 1, only gac particle diameter is 5 microns, and add-on is 34.5 grams, and ammonium metavanadate add-on is 0.6 gram, and ammonium heptamolybdate add-on is 0.83 gram. The mass of the ammonium bicarbonate solution was 750 grams, the mass concentration of the ammonium bicarbonate solution was 24.5%, the heat treatment temperature was 155° C., and the treatment time was 5 hours to obtain the residual oil hydrogenation protection agent carrier A3. The properties of the carrier are shown in Table 1. Among them, the length of the rod-shaped modified alumina in the micron-scale pores of the carrier is mainly 1.5-4.5 μm, the length of the rod-shaped modified alumina on the outer surface of the main modified alumina is mainly 3-8 μm, and the length of the rod-shaped modified alumina is mainly 3-8 μm. The diameter of the modified alumina is about 150-300nm, the coverage rate of rod-shaped modified alumina on the outer surface of the main modified alumina is about 84...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com