Preparation method of hydrodemetallization catalyst

A hydrodemetallization and catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex preparation process, achieve high activity, High-capacity metal capacity, the effect of increased active metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of rod-shaped alumina clusters:

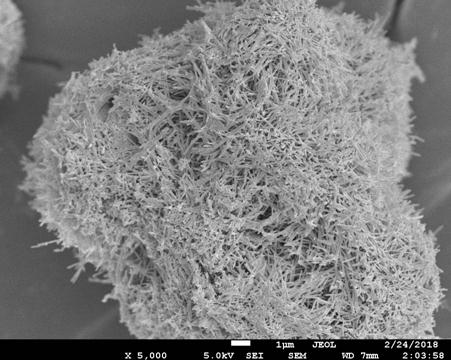

[0034] Weigh 200 grams of alumina powder, place it in 1200 grams of ammonium bicarbonate aqueous solution with a mass concentration of 17.5 wt%, seal it in a closed autoclave and heat-treat it at 130°C for 7 hours, filter and wash, and dry the material at 110°C for 6 Hours, rod-shaped alumina clusters A 1 , A 1 The scanning electron microscope image of figure 1 shown.

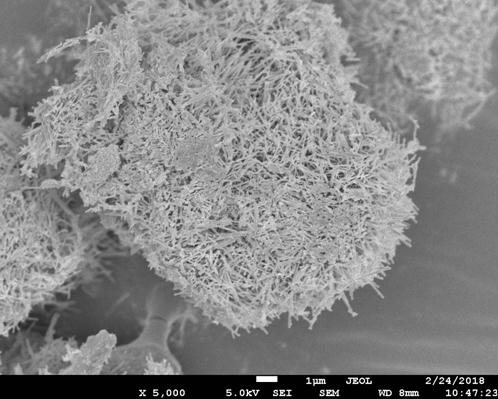

[0035] Weigh 200 grams of alumina powder, place it in 1600 grams of ammonium bicarbonate aqueous solution with a mass concentration of 13.5wt%, seal it in a closed autoclave and heat-treat at 140°C for 5 hours, filter and wash, and dry the material at 110°C for 6 Hours, rod-shaped alumina clusters A 2 , A 2 The scanning electron microscope image of figure 2 shown.

Embodiment 1

[0037] (1) Weigh the rod-shaped alumina cluster body A 1 100 g, impregnated with impregnating solution with molybdenum oxide concentration of 3.15g / 100mL and nickel oxide concentration of 0.55g / 100mL for 1 hour. Rod-shaped alumina clusters.

[0038] (2) Weigh 170 grams of pseudo-boehmite, step (1) 100 grams of modified rod-shaped alumina clusters, 0.3 grams of scallop powder, mix the above materials evenly, and add an appropriate amount of acetic acid aqueous solution with a mass concentration of 1%. Kneading, extrusion molding, drying the molded product at 120°C for 6 hours, and roasting the dried product at 650°C for 5 hours in an air atmosphere to obtain the carrier I.

[0039] (3) Weigh 100 grams of carrier I in step (2), 180 grams of ammonium bicarbonate, 650 grams of water, stir magnetically for 40 minutes, then transfer the mixture into an autoclave and seal it at 145°C for 5.5 hours. Dry at 120°C for 6 hours, and then bake the dried product at 500°C for 5 hours in an...

Embodiment 2

[0042] Same as Example 1, except that step (1) the concentration of molybdenum oxide in the impregnating solution is 3.0g / 100mL, and the concentration of nickel oxide is 0.65g / 100mL; step (2) the amount of pseudo-boehmite added is 350 grams; step (3 ) The amount of ammonium bicarbonate added is 230 grams, the amount of water added is 750 grams, the sealing heat treatment temperature is 135 ° C, and the treatment time is 6.5 hours; the concentration of molybdenum oxide in the impregnation solution in step (4) is 9.45 g / 100 mL, nickel oxide The concentration is 3.45g / 100mL, and the catalyst Cat2 is prepared, and the properties of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com