Preparation method of carbon-containing hydrodemetallization catalyst

A hydrodemetallization and catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve incomplete hydrodemetallization reactions and catalyst accumulation Carbon deactivation and other issues, to achieve the effect of mass transfer and diffusion, improve mechanical strength, high metal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

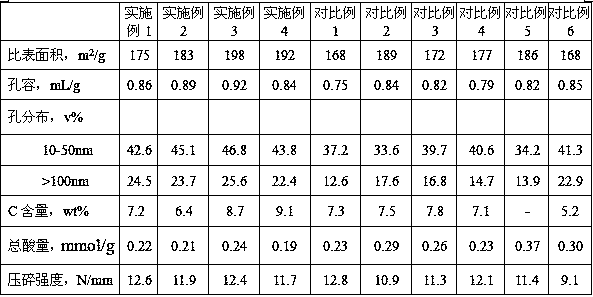

Embodiment 1

[0039] (1) Weigh 100 grams of alumina powder and place it in 630 grams of ammonium bicarbonate aqueous solution with a mass concentration of 16.8wt%. After sealing in a closed autoclave, heat treat at 135°C for 7 hours, filter and wash the material at 110°C Drying for 6 hours, soaking the above-mentioned materials with a xylitol solution with a mass concentration of 8.5% to obtain modified rod-shaped alumina clusters;

[0040] (2) Mix 200g of pseudo-boehmite, 45g of modified rod-shaped alumina clusters and 3g of scallop powder evenly, add an appropriate amount of aqueous solution dissolved in 4g of acetic acid, knead, extrude, and dry the molded product at 140°C for 6 hours , and then use 35ml mass concentration of 27.5wt% xylitol aqueous solution to impregnate the carrier by unsaturated spraying, then successively dry at 140°C for 6 hours, bake at 720°C for 6 hours under nitrogen atmosphere, and treat with 1250W microwave for 255s under nitrogen atmosphere to obtain Carbon al...

Embodiment 2

[0042] With embodiment 1, just the consumption of ammonium bicarbonate solution is 860 grams, and the mass concentration of solution is 15.6%. The heat treatment temperature was 155° C., and the treatment time was 4.5 hours. The mass concentration of carbon-containing precursor solution I is 7.3%, the amount of modified rod-shaped alumina clusters added is 36 grams, the mass concentration of carbon-containing precursor solution II is 30.5%, the dosage is 30ml, and the roasting temperature is 750°C under nitrogen atmosphere , the microwave treatment power was 1050W, and the treatment time was 275s, and the carbon-containing alumina carrier was obtained. The properties of the carrier are shown in Table 1.

Embodiment 3

[0044] With embodiment 1, just the consumption of ammonium bicarbonate solution is 540 grams, and the mass concentration of solution is 19.3%. The heat treatment temperature was 145° C., and the treatment time was 5.5 hours. The mass concentration of carbon-containing precursor solution I is 6.5%, the amount of modified rod-shaped alumina clusters added is 55 grams, the mass concentration of carbon-containing precursor solution II is 33.5%, the dosage is 22ml, and the roasting temperature is 700°C under nitrogen atmosphere , the microwave treatment power was 1350W, and the treatment time was 230s, and the carbon-containing alumina carrier was obtained. The properties of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com