Spherical hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst carriers, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve problems such as uneven distribution of additives, achieve concentrated particle size distribution, improve comprehensive performance, and crystallize high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

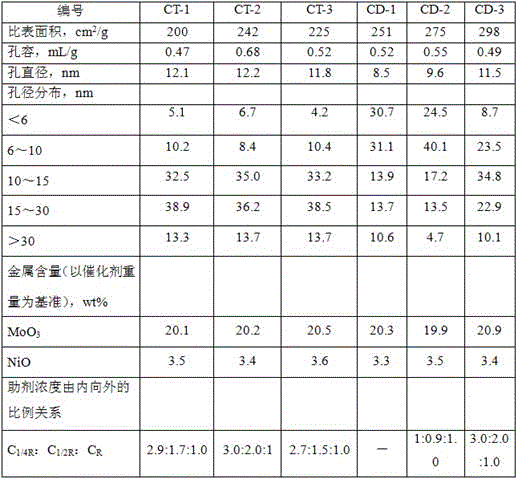

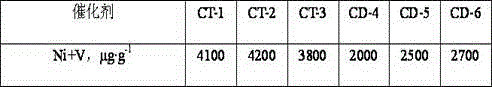

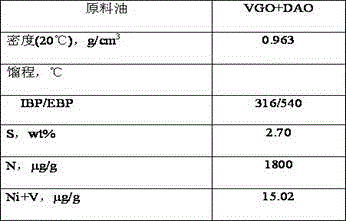

Examples

Embodiment 1

[0046] 400g of triethylammonium chloride, 220g of sodium hexafluorophosphate, and 450g of pure water were mixed, heated to 90°C under stirring, kept at a constant temperature for 3 hours, clarified, naturally cooled to about 30°C, and centrifuged to filter out the solid to obtain 450g of ionic liquid I. The water content is about 3.5wt%, and the yield is 72wt%.

[0047] Trimethylphenylammonium chloride 500g, sodium hexafluorophosphate 260g, pure water 450g, mix, heat to 90°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge and filter out the solid to obtain the ionic liquid II 550g, water content about 3.5wt%, yield 74wt%.

[0048] Add 15g of ionic liquid I and 2L of distilled water into the reaction kettle, adjust the reaction temperature to 60°C, mix sodium metaaluminate (calculated as alumina, the concentration is 26g / mL) and aluminum sulfate (calculated as alumina, the concentration is 8g / mL) ) parallel flow for neutraliz...

Embodiment 2

[0056] Triethylammonium chloride 300g, sodium hexafluorophosphate 160g, pure water 350g, mixed, heated to 100°C under stirring, kept at constant temperature for 2.5h, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain 420g of ionic liquid II , the water content is about 3.7wt%, and the yield is 72wt%.

[0057] Dimethylphenylammonium chloride 600g, sodium hexafluorophosphate 300g, pure water 550g, mix, heat to 70°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge and filter out the solid to obtain an ionic liquid Ⅲ550g, water content about 4.0wt%, yield 74wt%.

[0058] Add 20g of ionic liquid I and 2L of distilled water into the reaction kettle, adjust the reaction temperature to 60°C, mix sodium metaaluminate (calculated as alumina, the concentration is 26g / mL) and aluminum sulfate (calculated as alumina, the concentration is 8g / mL) ) parallel flow for neutralization reaction, the pH valu...

Embodiment 3

[0066] Tetraethylammonium chloride 450g, sodium hexafluorophosphate 250g, pure water 500g, mixed, heated to 90°C under stirring, kept at constant temperature for 3 hours, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain 650g of ionic liquid II, The water content is about 3.9wt%, and the yield is 75wt%.

[0067] 500g of methyl phenyl ammonium chloride, 260g of sodium hexafluorophosphate, 450g of pure water, mix, heat to 90°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge and filter out the solid to obtain 550g of ionic liquid III , the water content is about 3.5wt%, and the yield is 74wt%.

[0068] Add 24g of ionic liquid I and 2L of distilled water into the reaction kettle, adjust the reaction temperature to 65°C, mix sodium metaaluminate (calculated as alumina, the concentration is 26g / mL) and aluminum sulfate (calculated as alumina, the concentration is 8g / mL) ) parallel flow for ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com