Preparation method of heavy oil hydrodemetallization catalyst

A heavy oil hydrogenation and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem that the pore volume of the catalyst needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

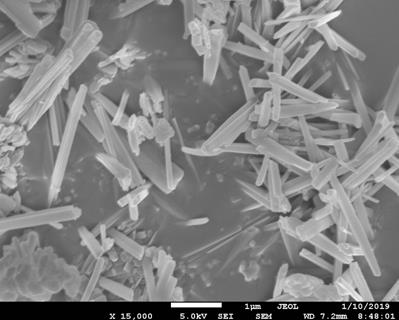

[0037] Preparation of pretreatment material A:

[0038] Take the spent catalyst crushed to more than 230 mesh, roast it at 750°C for 8 hours, weigh 100 grams of the above spent catalyst, place it in 700 grams of ammonium bicarbonate aqueous solution with a concentration of 20% by mass, and transfer the mixed material into an autoclave Heat treatment at 145°C for 6 hours after sealing, and then dry the powder at 110°C for 6 hours. The aluminum oxide was submerged in a solution of polyethylene glycol-6000 (average molecular weight 6000) with a concentration of 30% by mass for 1.5 hours, and then the carrier was dried at 120°C for 6 hours to obtain the pretreated material A-I.

[0039] Take the spent catalyst crushed to more than 230 mesh, roast it at 800°C for 8 hours, weigh 100 grams of the above spent catalyst, place it in 600 grams of ammonium bicarbonate aqueous solution with a concentration of 22.5% by mass, and transfer the mixed material into an autoclave Heat treatment ...

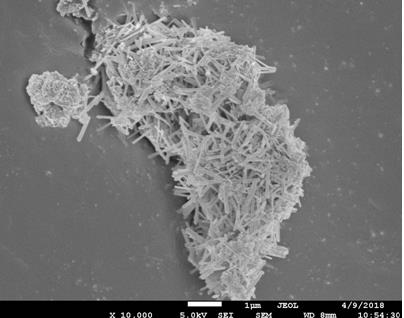

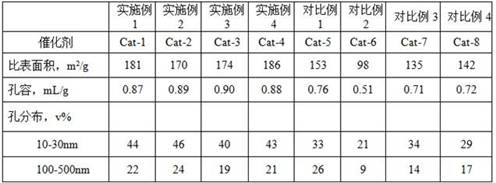

Embodiment 1

[0044] Weigh 100 grams of pseudo-boehmite, 20 grams of the above-mentioned pretreatment material A-I, 16 grams of the pretreatment material B-I, 2 grams of scallop powder, mix the above-mentioned materials evenly, add an appropriate amount of aqueous solution containing 3 grams of acetic acid and knead, squeeze The strips are formed, and the formed product is dried at 140°C for 6 hours, and the dried product is calcined at 700°C for 5 hours in air to prepare an alumina carrier.

[0045] Weigh 50 grams each of the above-mentioned alumina supports, add 100 mL of Mo-Ni-P solution (to make the final catalyst contain MoO 3 10.3wt%, containing NiO 3.1wt%) impregnated for 2 hours, filtered off the excess solution, dried at 120°C, and then roasted at 450°C for 5 hours to obtain the demetallization catalyst Cat-1 of the present invention, the catalyst properties are shown in Table 1 .

Embodiment 2

[0047] Same as Example 1, except that the amount of pretreatment material A-I was 25 grams, and the amount of pretreatment material B-I was 14 grams, and the demetallization catalyst Cat-2 of the present invention was obtained. The properties of the catalyst are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com