Patents

Literature

46results about How to "Improve surface chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycosaminoglycan and Synthetic Polymer Material for Blood-Contacting Applications

ActiveUS20150196688A1Improve surface chemistryFeasible at commercial productionSuture equipmentsOrganic active ingredientsLow-density polyethyleneLinear low-density polyethylene

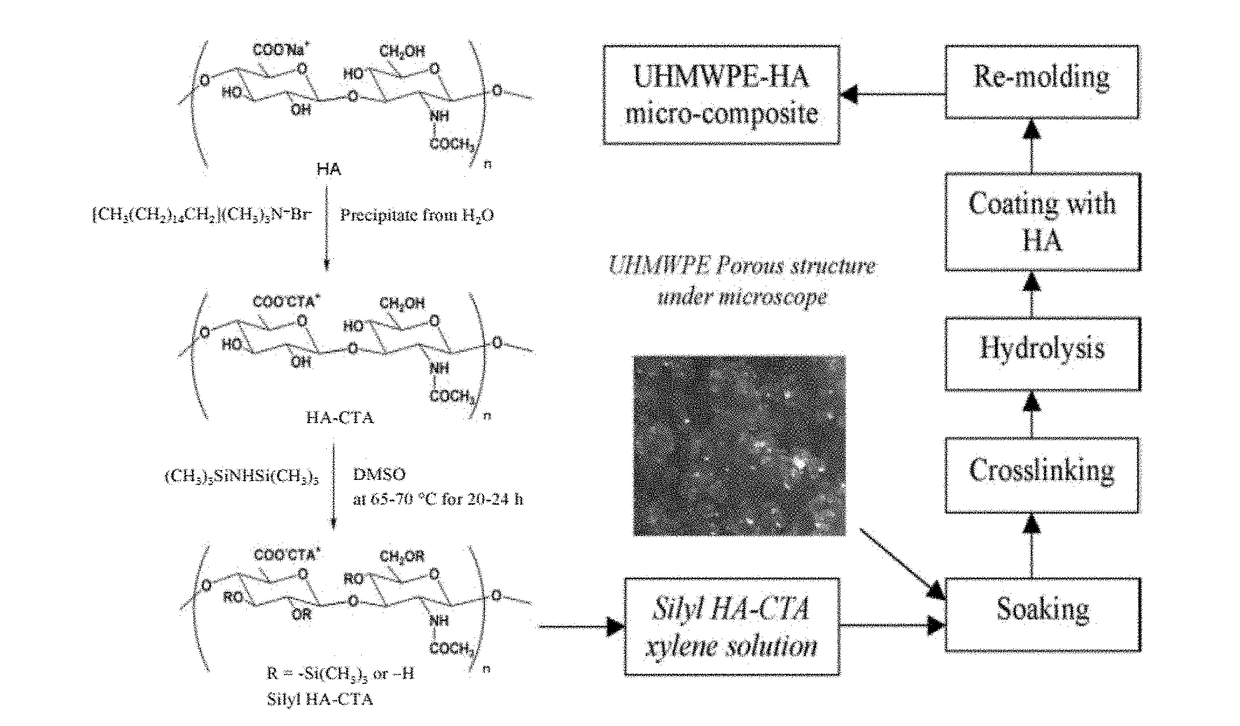

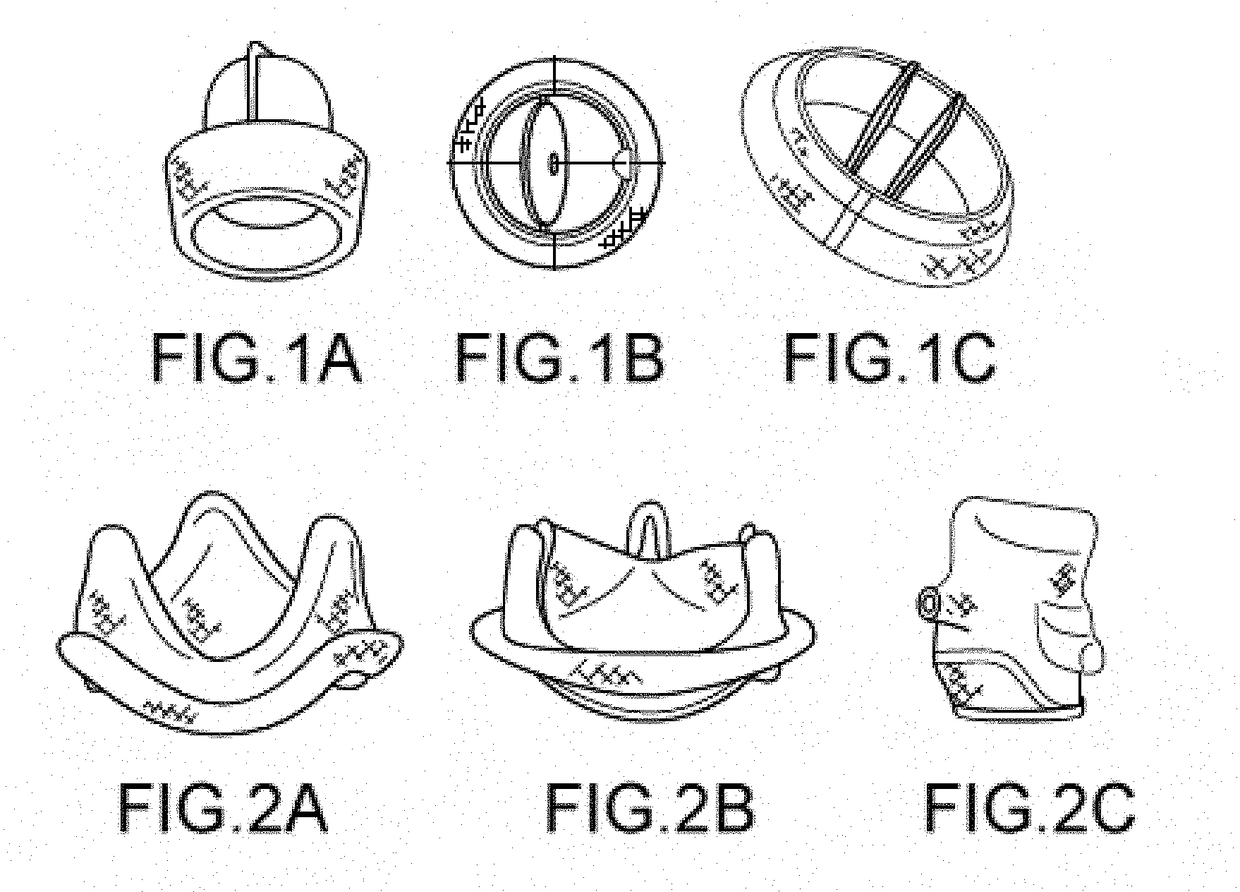

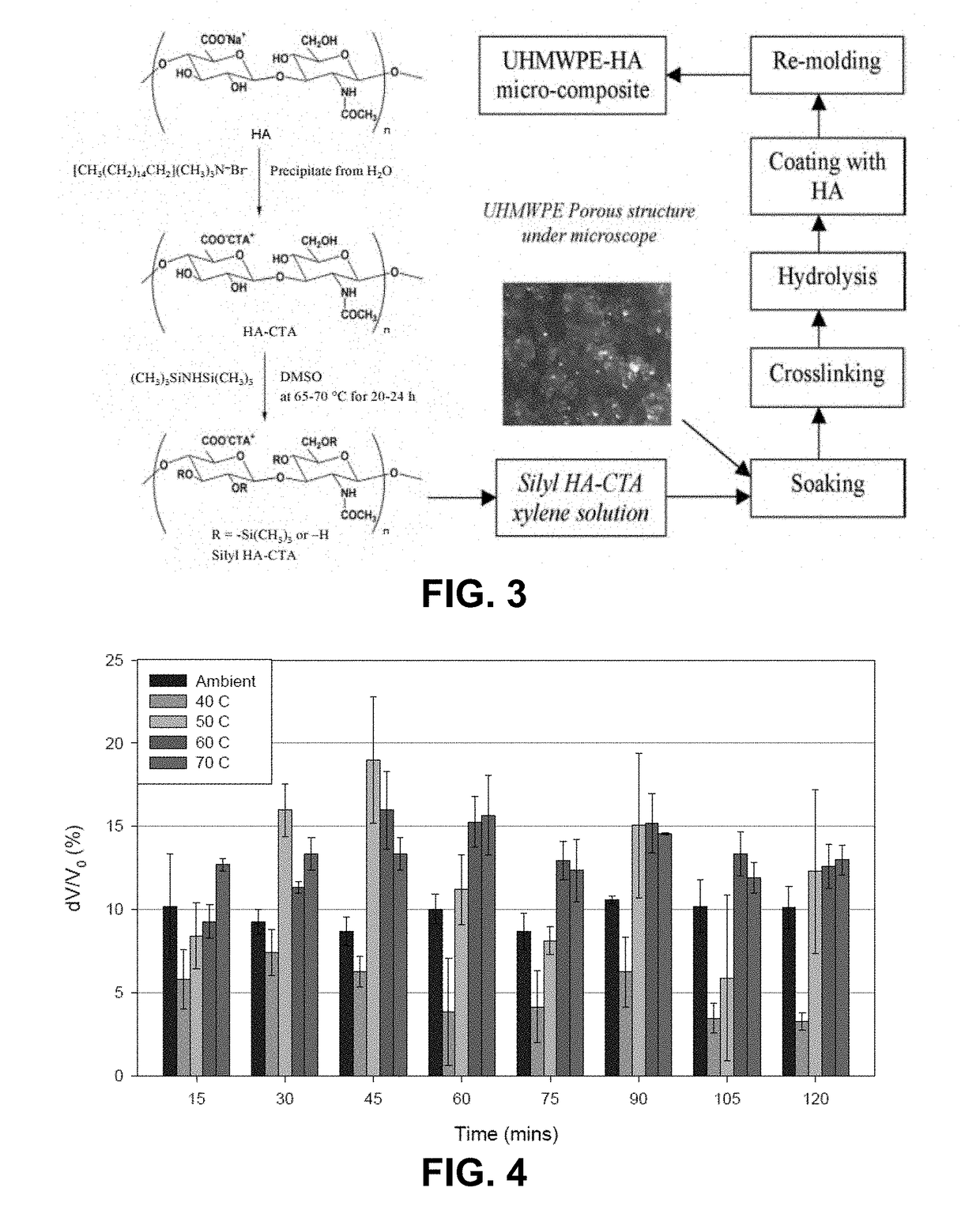

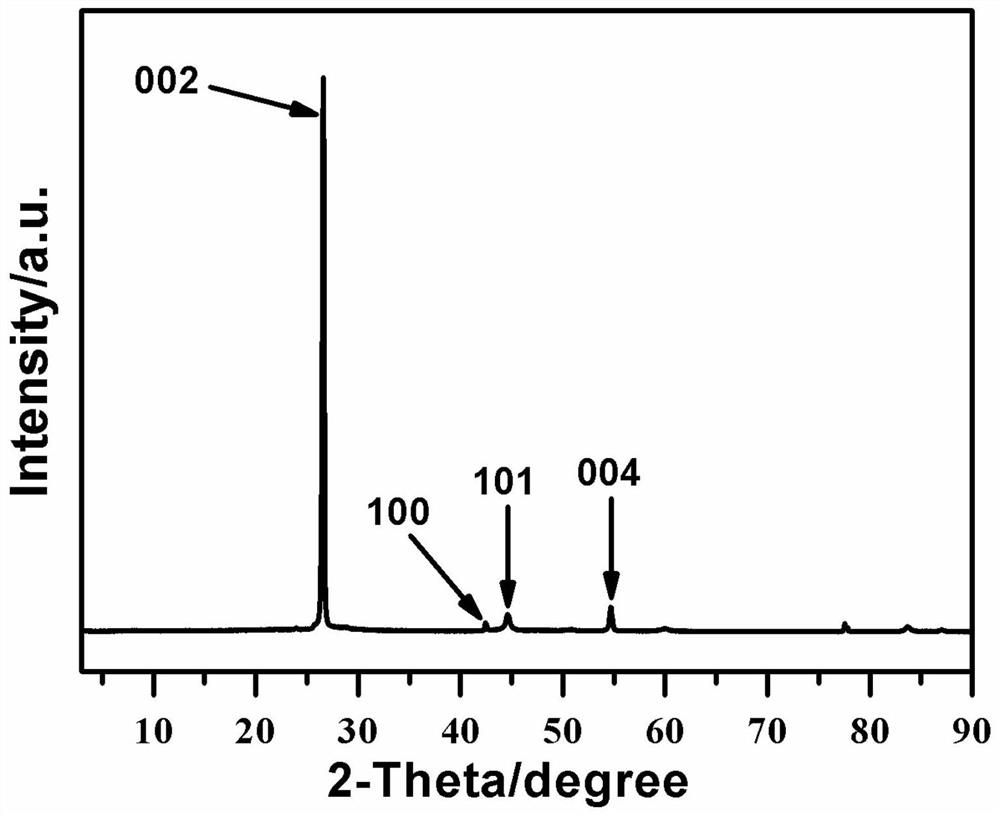

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), and polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

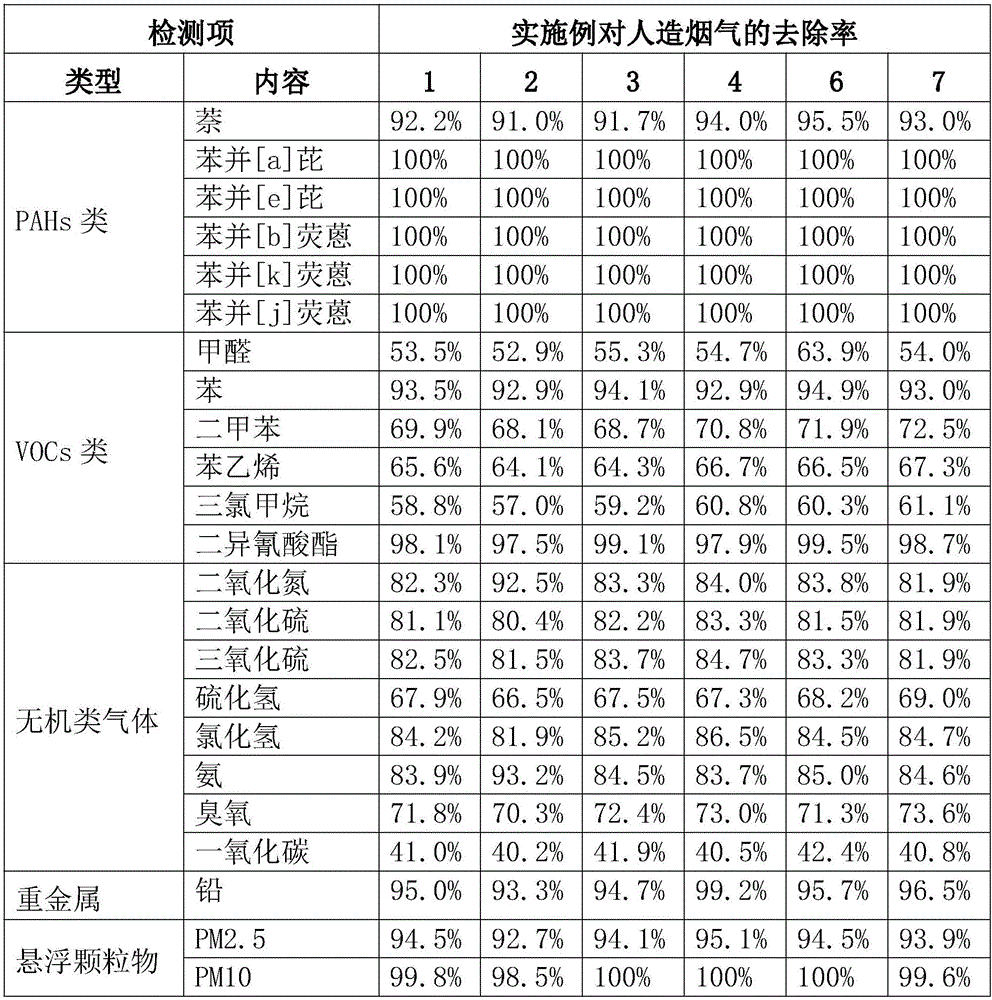

Graphene material coating and preparing method thereof and air filtering device and system

InactiveCN106192376AImprove adsorption capacityUniform circulationGas treatmentDispersed particle filtrationHazardous substanceAir filter

The invention relates to the technical field of air filtering, in particular to a graphene material coating and a preparing method thereof, and further relates to an a air filtering device and system based on the graphene material coating. The preparing method of the graphene material coating includes the following steps that S1, slurry-dispersion raw liquid is prepared, wherein a dispersing agent and a bonding agent are added into a solvent, and the mixture is stirred to generate the slurry-dispersion raw liquid; S2, a graphene surface coating is formed, wherein graphene powder is added into the slurry-dispersion raw liquid, the mixture is stirred to allow slurry to be even to be applied to the surface of a carrier, drying is carried out, and the graphene-material-coating finished product is obtained. By means of the graphene material coating and the preparing method thereof, the adsorption rate of hazardous substances in gas can be increased, and secondary pollution caused by unfirm adsorption is avoided.

Owner:张麟德

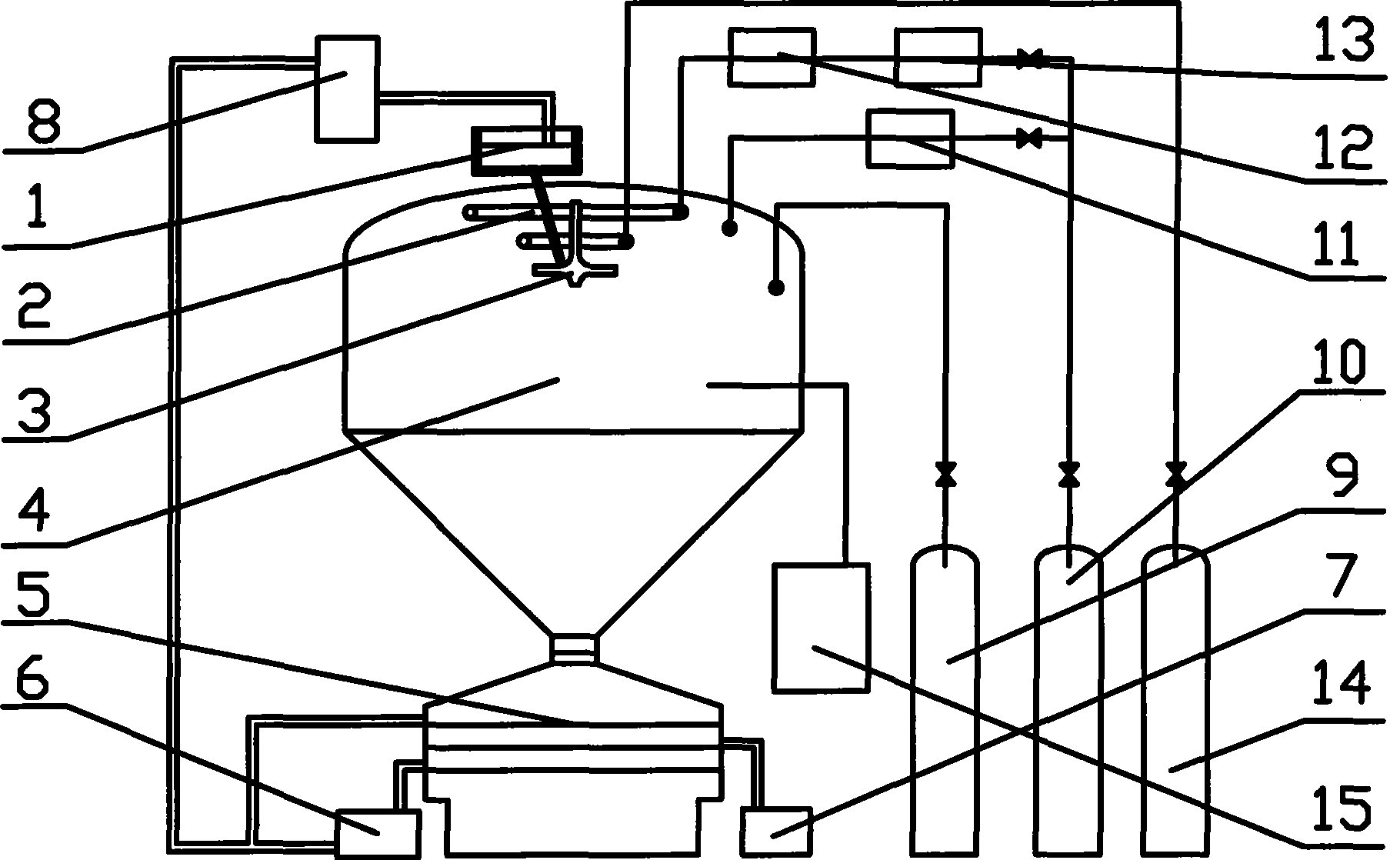

Preparation method of continuous high quality soldering powder

The invention discloses a method for preparing alloy powder, more particularly relates to a method for continuously preparing high-quality tin alloy welding powder. The invention is characterized in that an atomizing chamber is vacuumed, then inert protection gas is filled into the atomizing chamber; the tin alloy material is melted in a melting furnace, and then is controlled to be atomized in the atomizing chamber; after being cooled, the tin alloy material is solidified into tin alloy powder grain; by the sieving of the equipment, the needed product is obtained; products not meeting the requirements is melted and prepared again. The invention has the advantage that the quality of tin alloy powder is greatly improved by optimizing producing condition; the surface chemical property is improved; the productive labor cost can be greatly lowered; high priority is given to environmental protection in the process of realizing a circular production process. Products prepared by the method can be widely applied to encapsulation and circuit board welding material in electronic industry.

Owner:HUIJIN ATOMIZING SCI

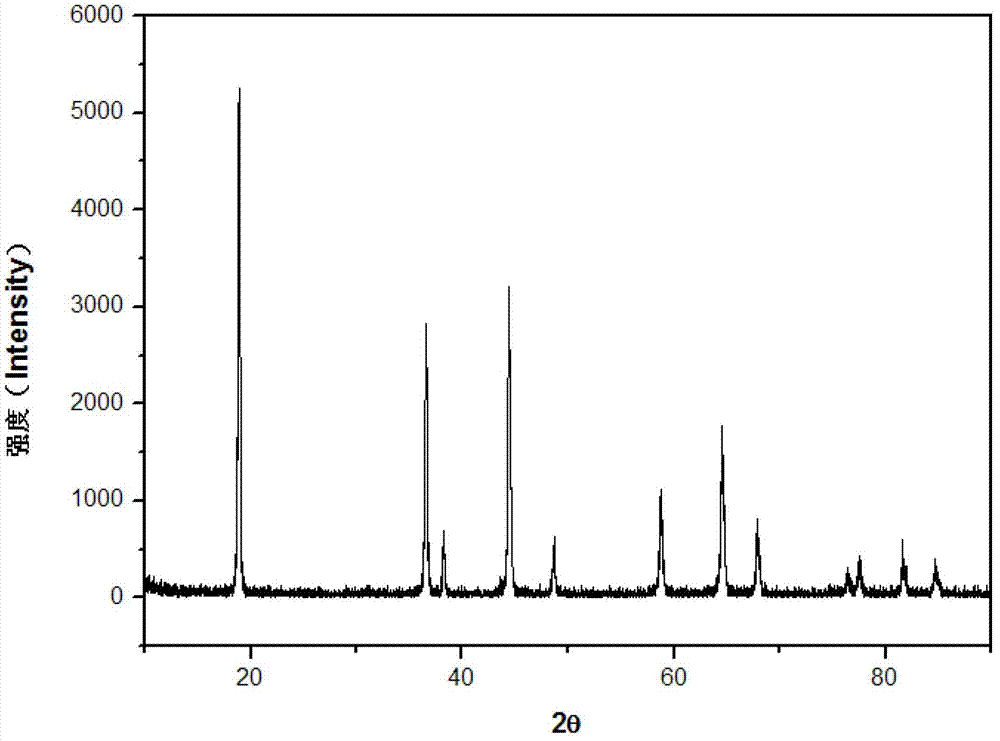

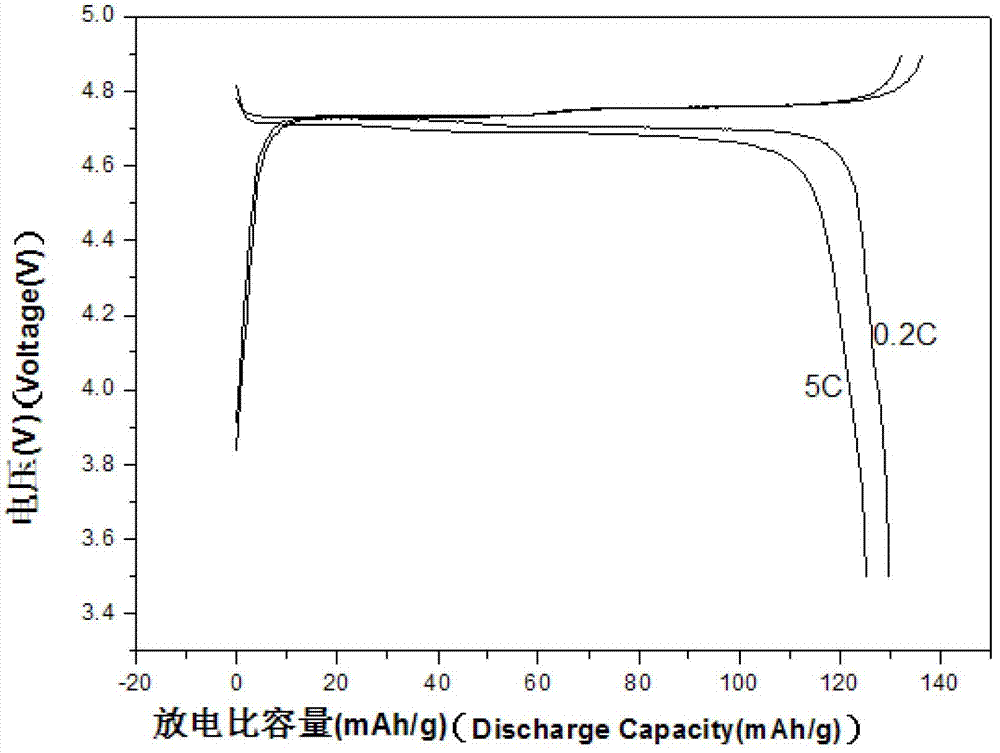

Surface coating method of 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4

ActiveCN103094552AImprove surface chemistryImprove conductivityElectrode thermal treatmentTube furnacePhysical chemistry

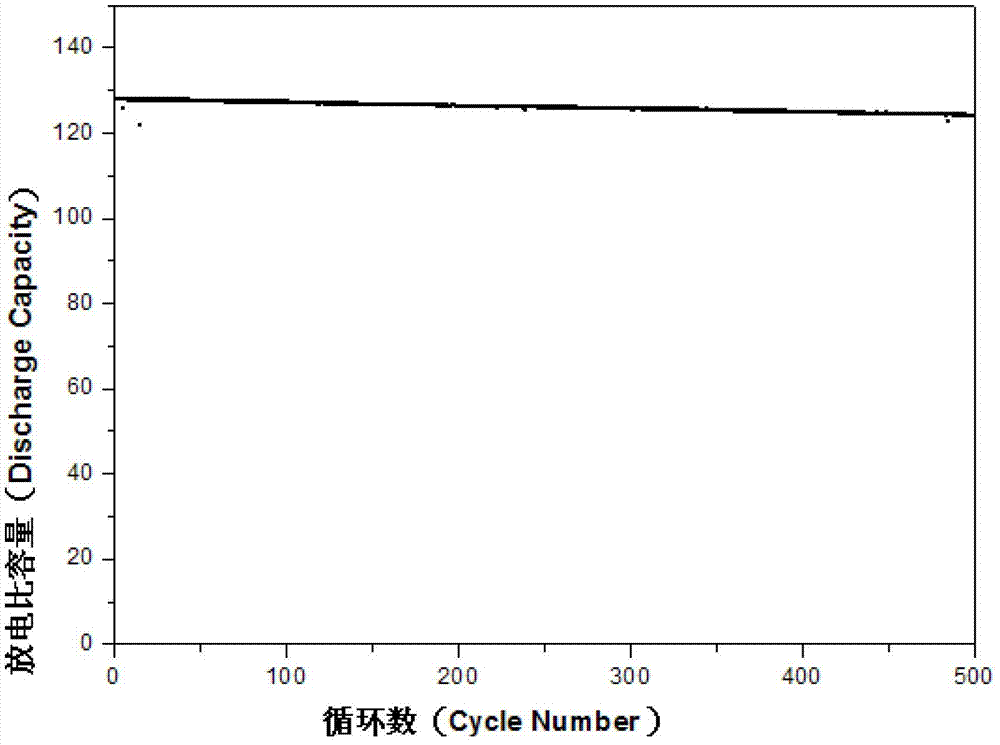

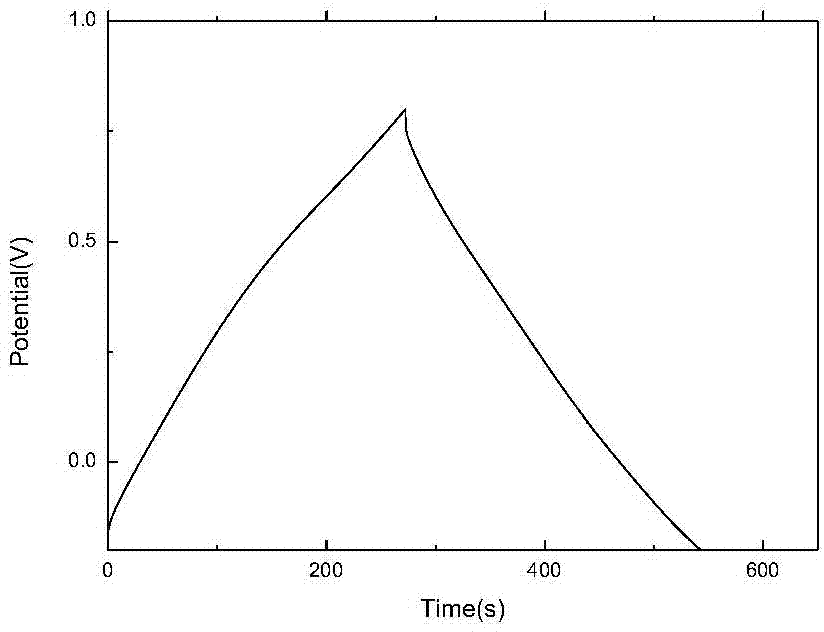

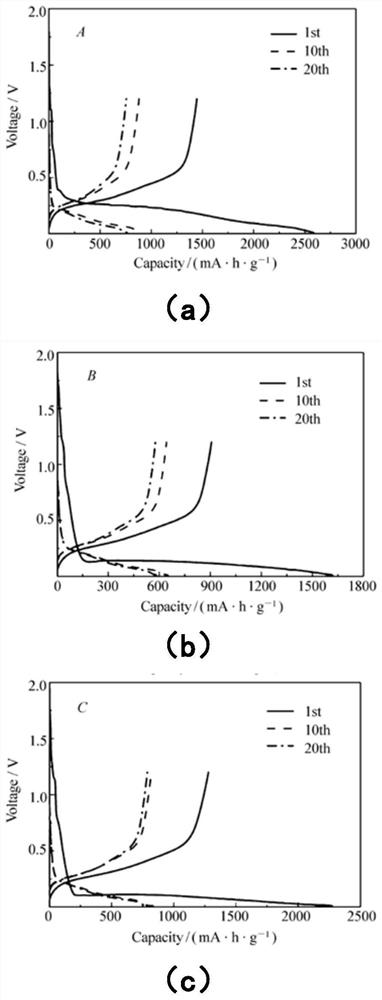

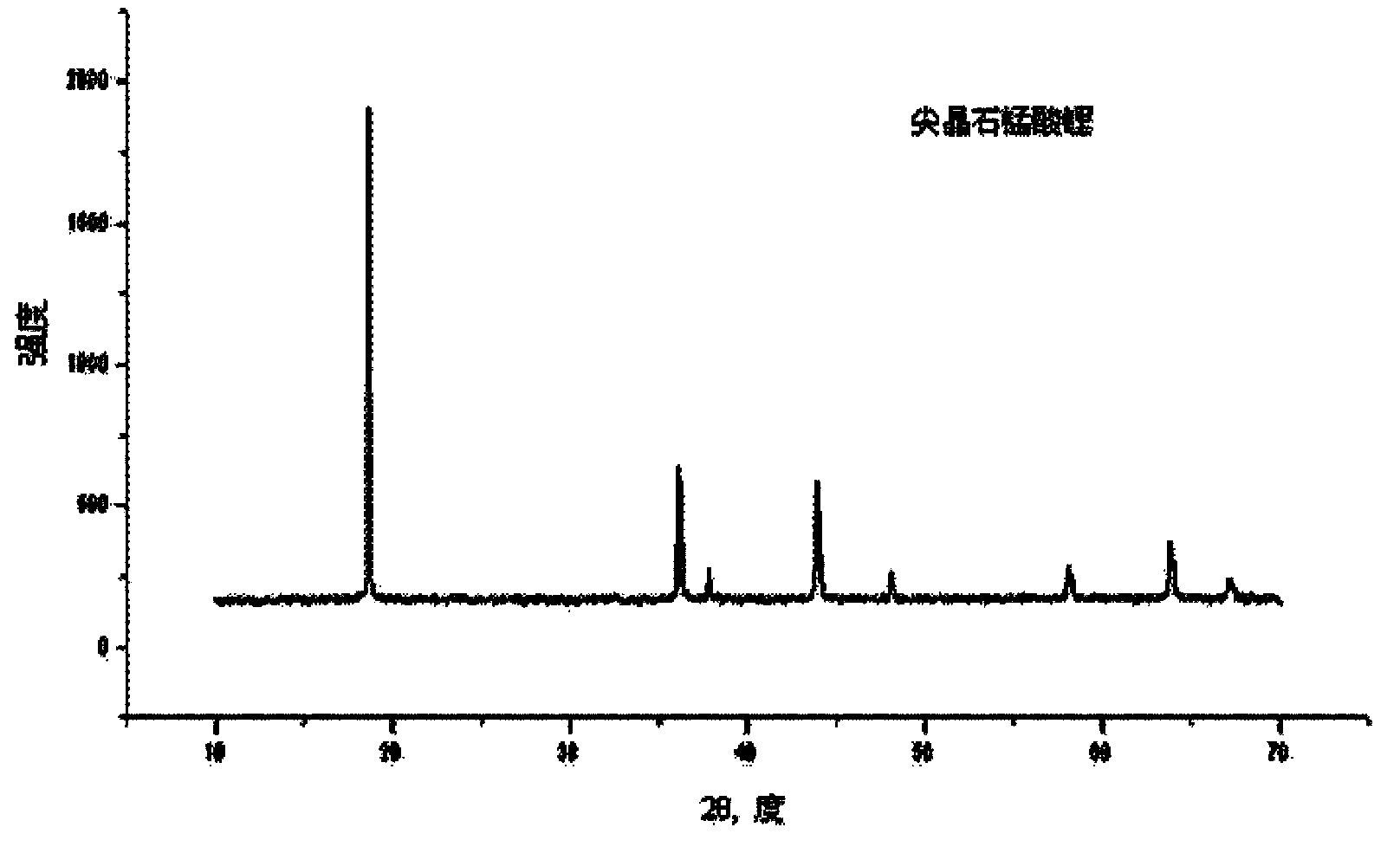

The invention discloses a surface coating method of a 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4, which comprises the following steps: (1) grinding and mixing a coating material or precursor thereof and a positive pole active material in a mass ratio of (1-50):100; (2) dispersing the mixture in a certain liquid-phase medium, and carrying out ultrasonic pulverization; (3) mixing the mixture and the medium by ball milling; (4) filtering and drying; and (5) putting the dried mixture in the step (4) into a pipe furnace, heating in inert gas at the heating speed of 1-30 DEG C / minute, calcining at the constant temperature of 200-500 DEG C for 1-5 hours, carrying out quick cooling or furnace cooling to room temperature, and grinding the coated high-voltage lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4. The product obtained by the method disclosed by the invention has high reversible specific capacity: the capacity retentivity after 500 2C charging / discharging cycles is higher than 95%, and the specific capacity of 5C discharge is more than 96% of 0.2C. The method has the advantages of simple and controllable synthesis technique and uniform coating, and is suitable for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

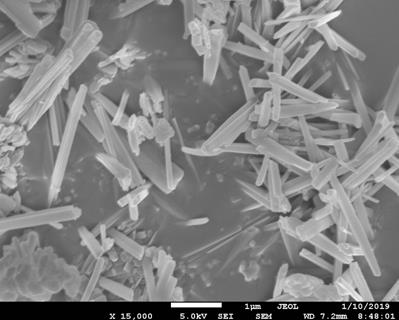

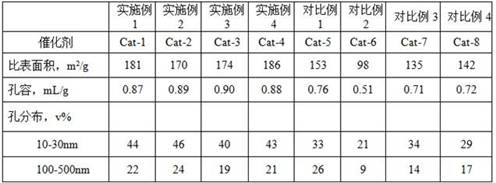

Preparation method of hydrodemetallization catalyst

ActiveCN106140187AIncrease profitGood effectMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsActive componentAcid property

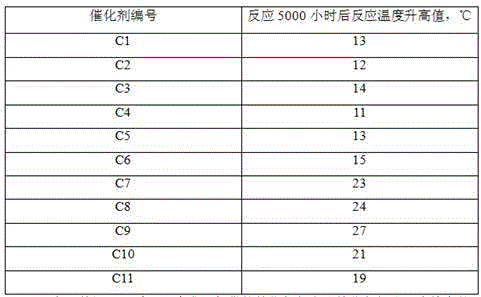

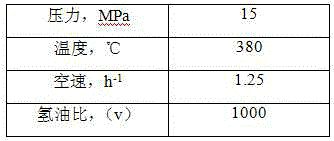

The invention discloses a preparation method of a hydrodemetallization catalyst. The method includes the following steps that 1, a physical pore-expanding agent I is soaked with an alkali-containing metal element solution I and hydrogenation active component soaking liquid I, a physical pore-expanding agent II is soaked with an alkali-containing metal element solution II and hydrogenation active component soaking liquid II, and the physical pore-expanding agent I and the physical pore-expanding agent II are dried and then soaked with an ammonium salt solution in a spraying mode for use; 2, the physical pore-expanding agent I and the physical pore-expanding agent II obtained in the step 1 are mixed with dry pseudo-boehmite gel powder, a chemical pore-expanding agent, an extrusion aid and a peptizing agent, the mixture is kneaded into plastic, strip extrusion is carried out, a formed material is subjected to heat treatment, the treated material is dried and roasted, and a modified alumina supporter is obtained; 3, the modified alumina supporter is soaked with hydrogenation active component soaking liquid III, and the catalyst is obtained through drying and roasting. The catalyst prepared through the method has a high active metal content at macropores and a low active metal content at micropores, the acid property at macropores is obviously improved, and the anti-carbon capacity of macropores is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

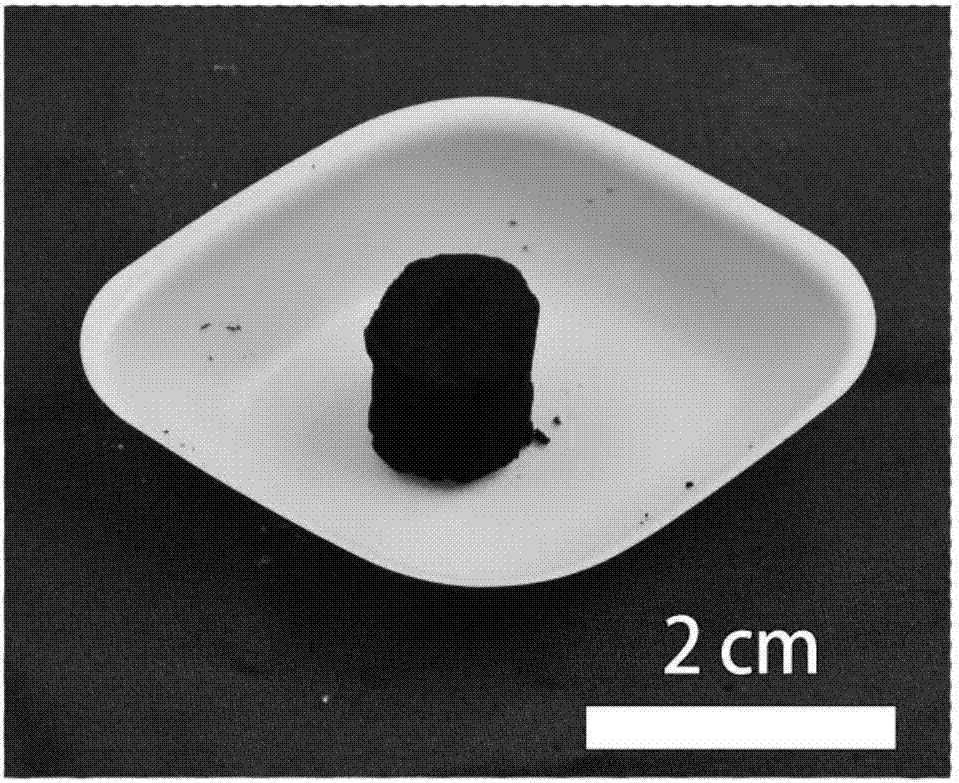

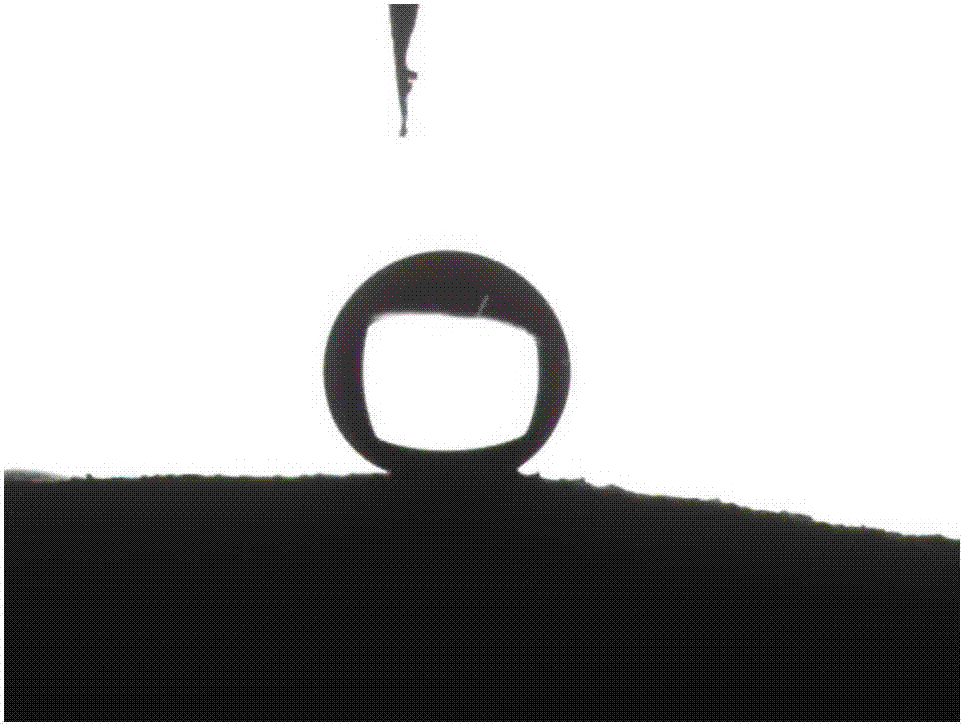

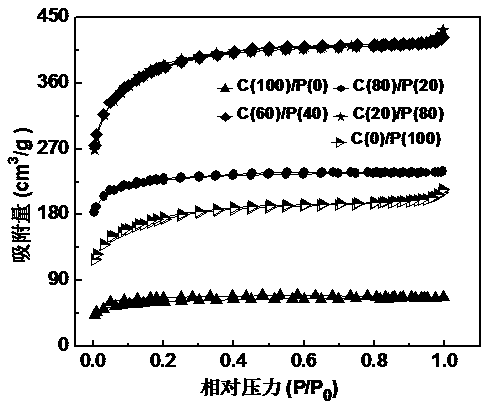

Three-dimensionalgraphene composite aerogel and preparation method thereof

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsCvd grapheneGraphite oxide

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

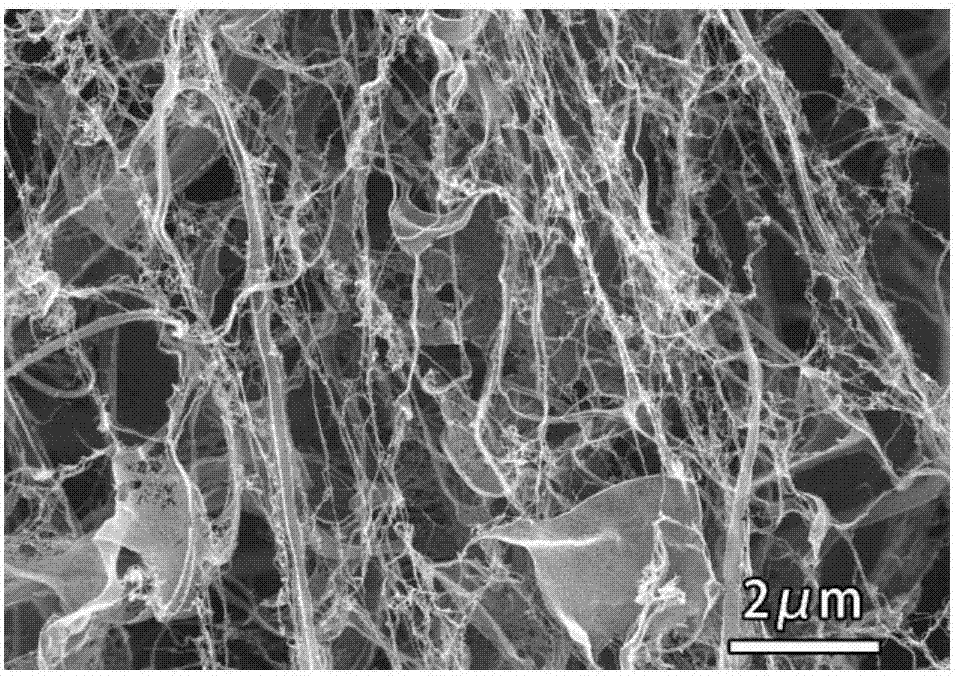

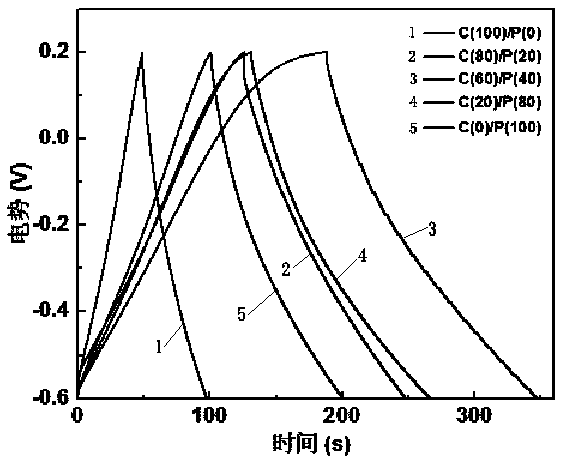

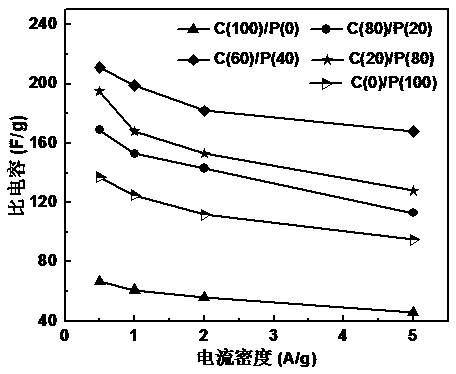

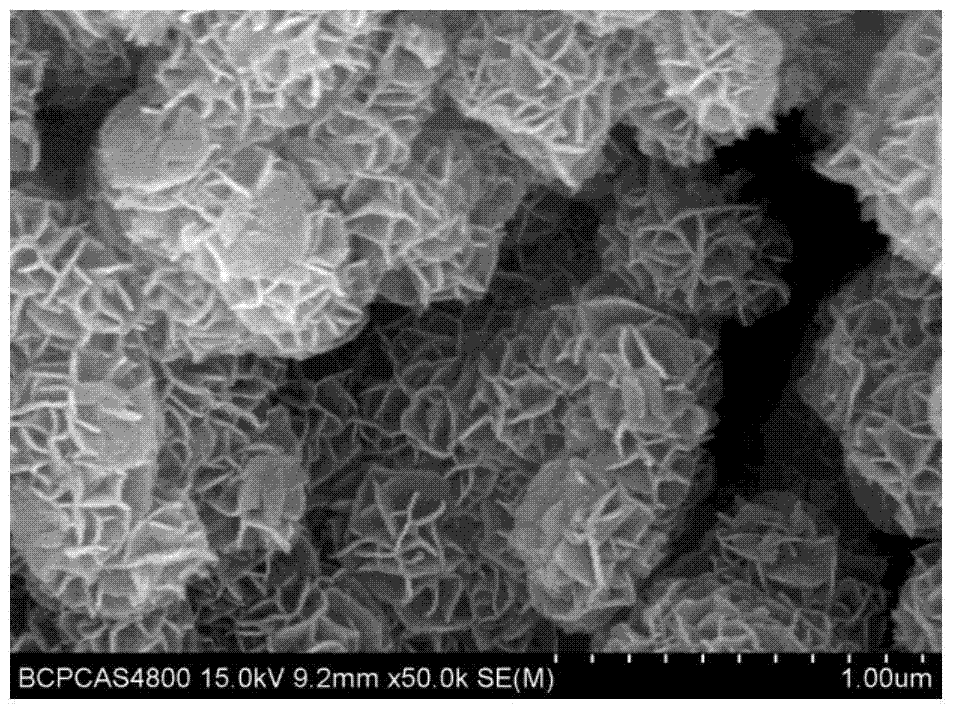

Preparation method of composite carbon nanofibers with high specific surface area

InactiveCN105506784AImprove surface chemistryLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesElectrospinningActivated carbon

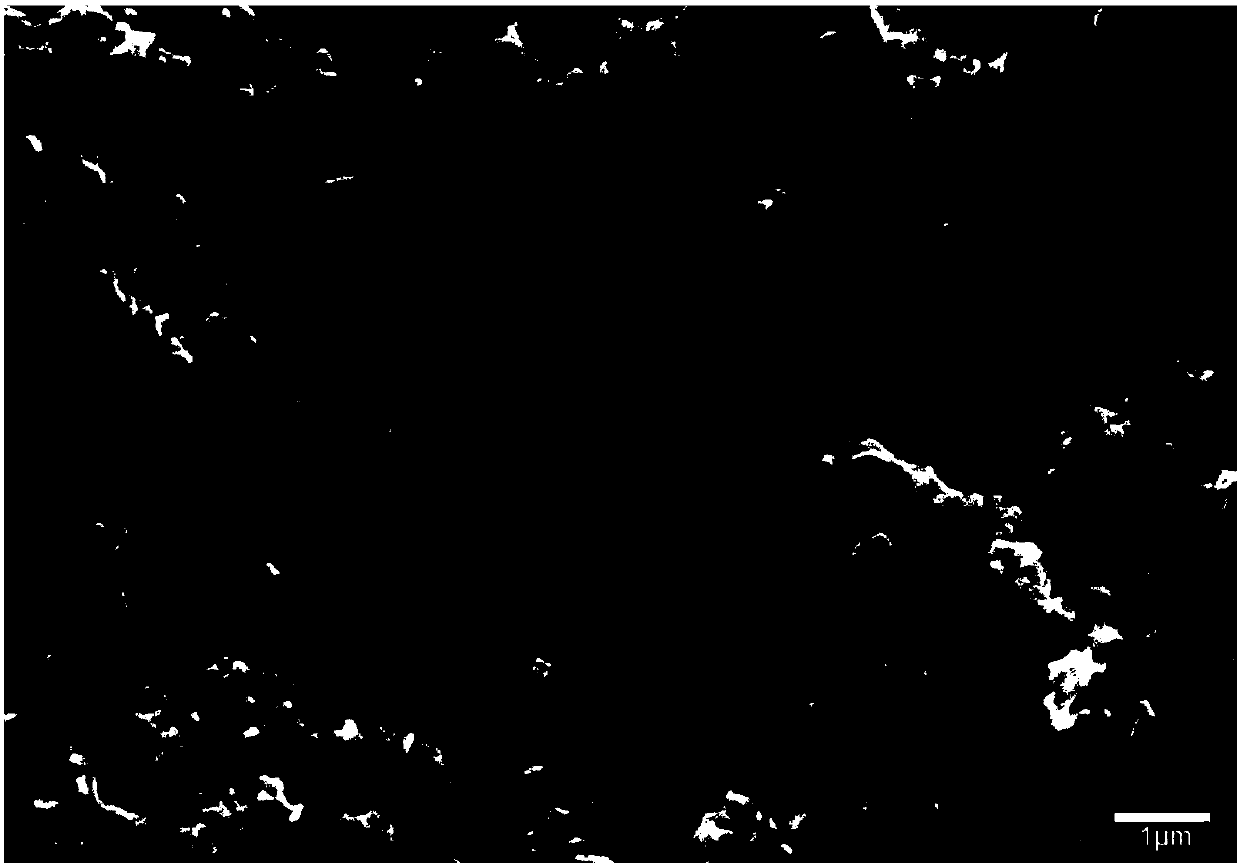

A preparation method of composite carbon nanofibers with a high specific surface area relates to the technical field of preparation of electrode materials of super capacitors, and comprises the following steps: mixing cellulose acetate and polyacrylonitrile to obtain a spinning solution; carrying out electrospinning to obtain CA / PAN precursors; pre-oxidazing the CA / PAN precursors; carrying out carbonization and actification to obtain CA / PAN activated carbon fibers; mixing the CA / PAN activated carbon fibers with acetylene black, PTFE and ethanol to obtain a mixture; putting the mixture into an oven; drying the mixture into paste; smearing the paste on nickel foam; carrying out drying and tabletting to obtain the CA / PAN composite carbon fiber electrode material. As cellulose acetate contains a large quantity of oxygen-containing groups, and has double functions of pore-forming and chemical surface modification, the hole structure, the specific capacitance and the specific surface area are greatly improved.

Owner:YANGZHOU UNIV

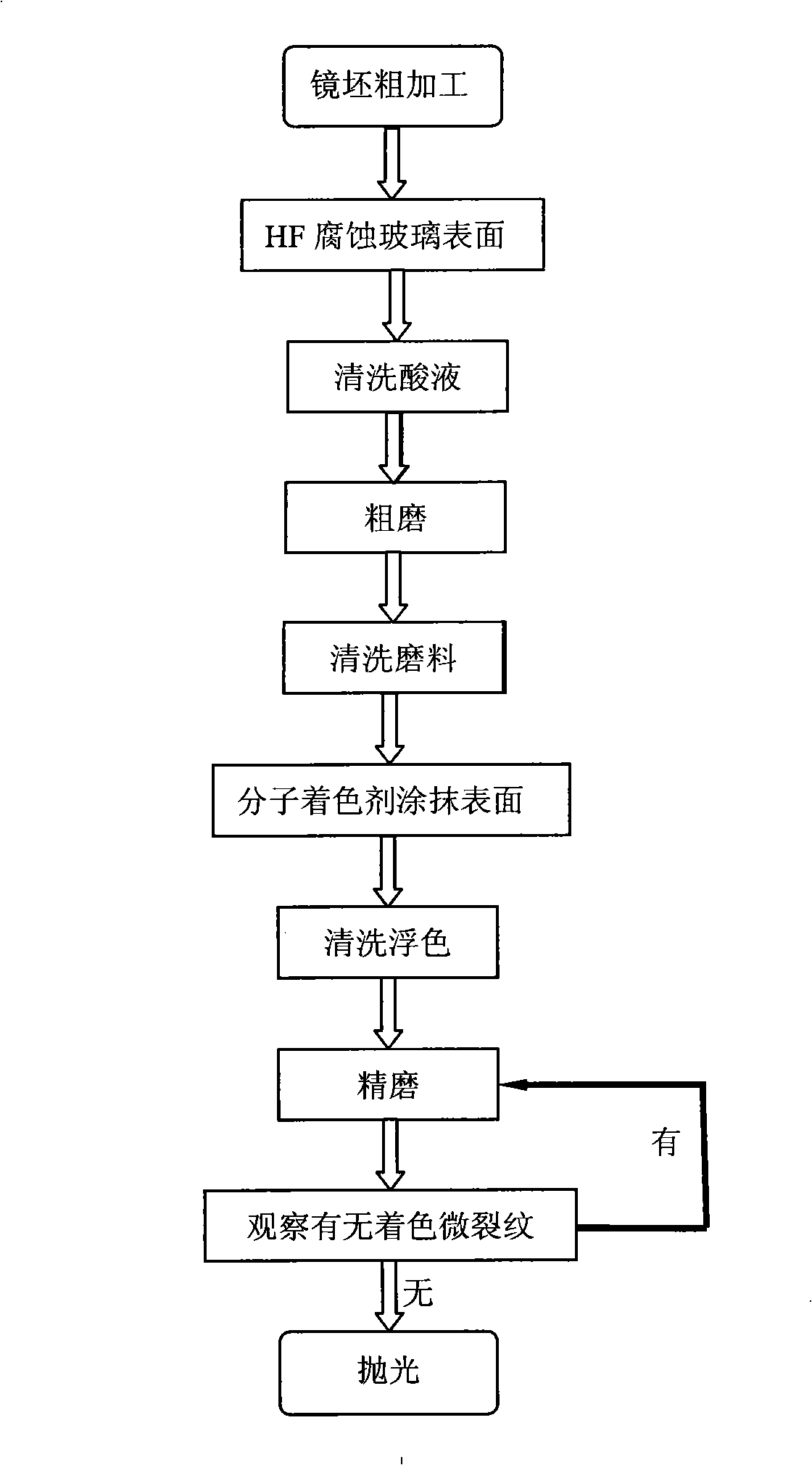

Method for glass micro-crack detection by molecule stainer

InactiveCN101403707AImprove surface chemistryImprove mechanical propertiesOptically investigating flaws/contaminationCrazingProcess quality

The invention provides a method used for detecting microcracks of glass by a molecule colorant, belonging to a real-time detection method in the technical field of optical cold working; the method comprises the steps as follows: after chunk glass is roughly machined, the chunk glass is arranged statically for several tens of hours so as to release the stress; subsequently, the surface of the chunk glass is corroded by acid, coated by the molecule colorant and arranged statically for several minutes; the colorant molecules infiltrate the interior of the microcrack passage till the bottom end by the compatibility of the glass on the aqueous solution and the scattering nature of the colorant; and the floating color on the surface of the chunk glass is washed away by water and the shape and depth of the microcrack can be clearly displayed, thus providing reliable basis for removing the microcrack. The method has the active effects that HF corrosion is used for reinforcing the chemical and mechanic performance of the glass surface, natural high-strength characteristic of the glass is partly recovered, the limits of microcrack theory detection method are overcome, the process flow is simplified, the processing time is saved, the processing cost is reduced, and the working efficiency and process quality are improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

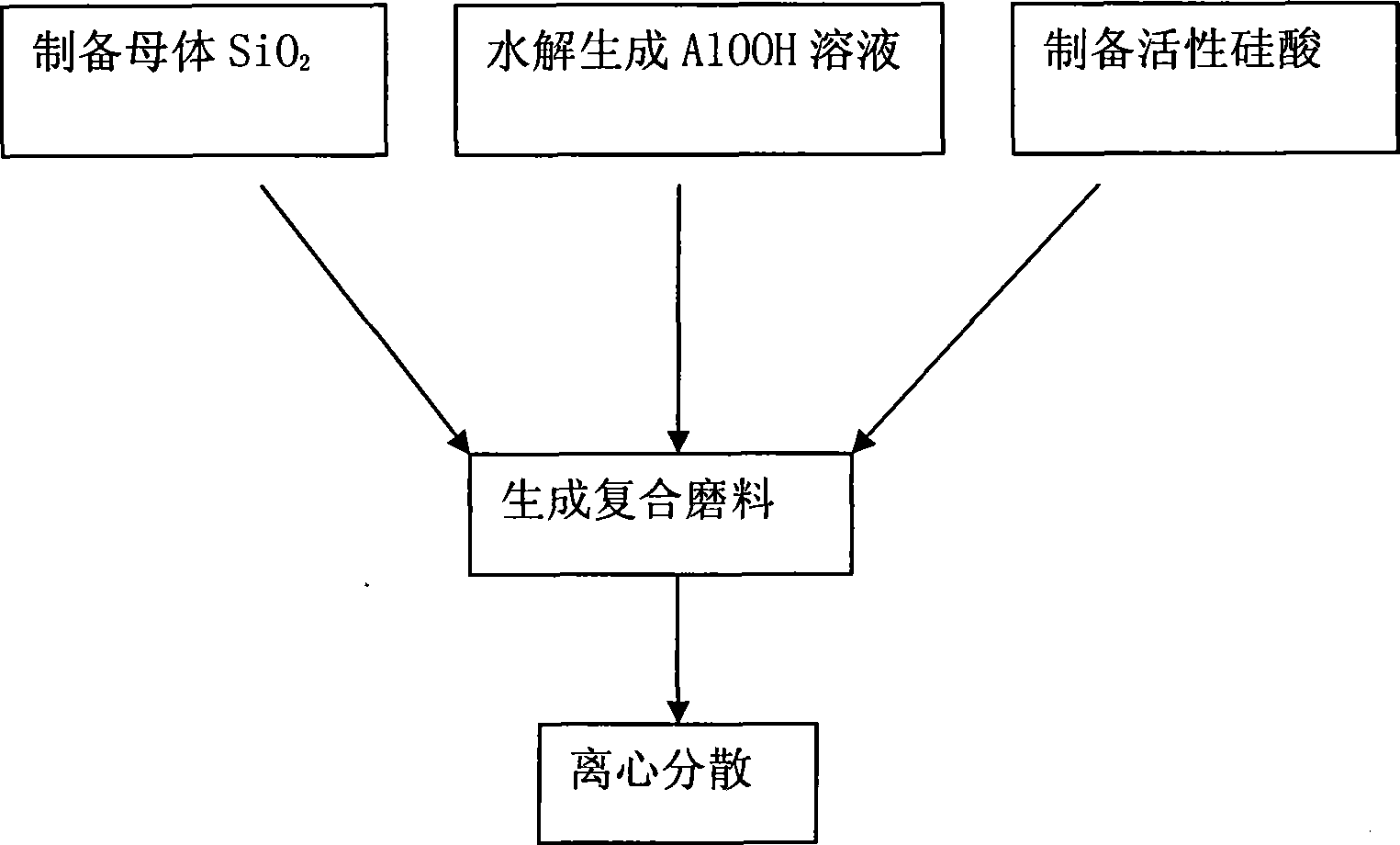

Grinding medium for chemico-mechanical polishing and preparation thereof

ActiveCN101372560AWide pH rangeImprove surface chemistryInorganic pigment treatmentPolishing compositions with abrasivesSilicic acidNano sio2

The invention provides an abrasive for chemical-mechanical polishing and a preparation method thereof. The abrasive is used in the field of chemical-mechanical polishing. The nano-SiO2 abrasive is diluted to the concentration lower than 10% (mass fraction) and taken as a growth matrix, the growth matrix is hydrolyzed by aluminum salt at the temperature of 80-90 DEG C, and then added with acid and aged at the temperature of 90-100 DEG C to prepare an acidic AlOOH solution. Water glass is diluted to lower than 10% to prepare active silicic acid by strong cation exchange resin. Finally, the AlOOH solution and the active silicic acid obtained are dropped into silica sol according to a particle growth method, added with a certain quantity of alkali to control the pH value ranging from 8 to 11, heated at a constant temperature and vigorously stirred, and aged for 2 hours. In the aluminum-silicon compound growing on the silicon base, the atomic ratio of aluminum and silicon can be controlled according to the ratio of the AlOOH to the active silicic acid. The abrasive obtained can expand the existing pH value range thereof, widen the application scope of the chemical-mechanical polishing, and improve the surface chemical properties.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

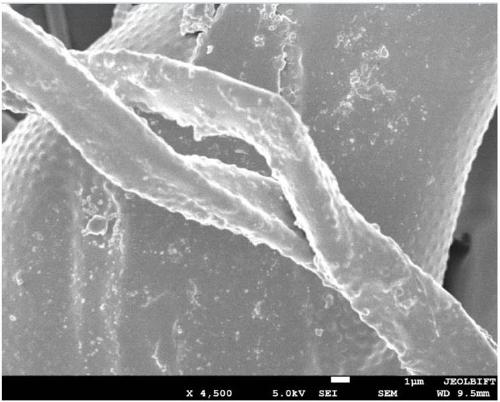

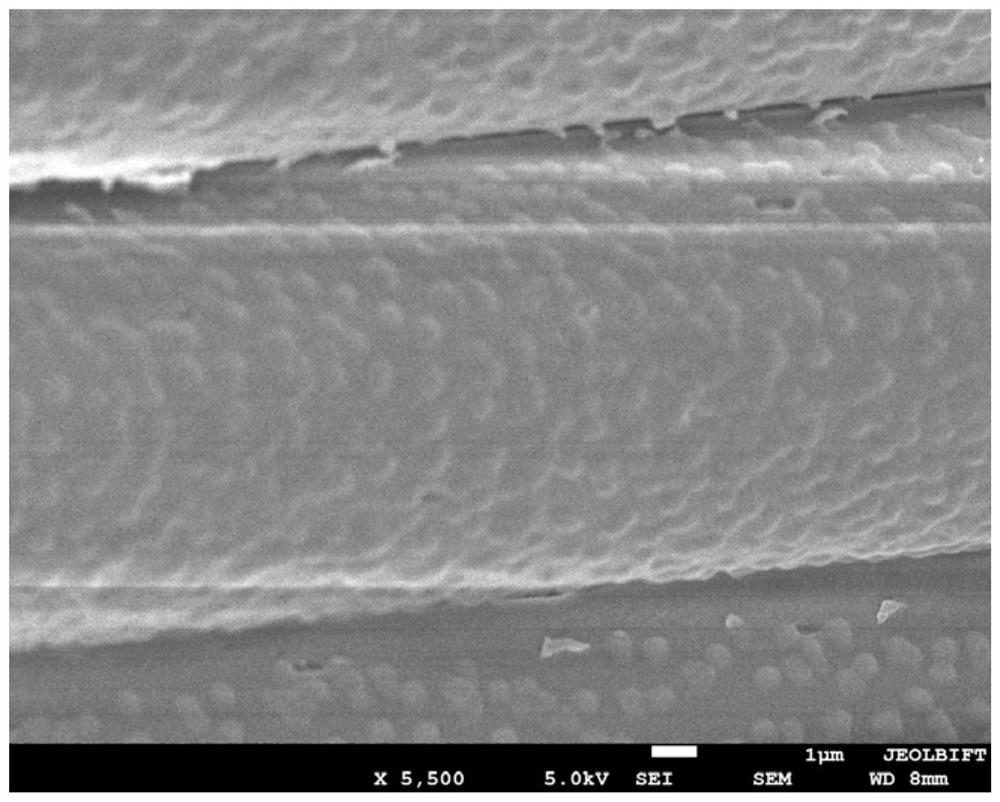

Polyester composite fiber with intelligent surface, and preparation method and application thereof

InactiveCN109385893ASpecial surface structureImprove hydrophilicity and hydrophobicityPhysical treatmentLiquid repellent fibresOil waterPolyester composite

The invention discloses a polyester composite fiber with an intelligent surface, and a preparation method and application thereof. The polyester composite fiber comprises a polyester fiber matrix andparticles covering the polyester fiber matrix, wherein the particles and the polyester fiber matrix are chemically bonded; preferably, the particles are polymer particles; more preferably, the particles are polymer particles with environmental response; thus, covering of the surface of the polyester fiber matrix with the particles can improve the hydrophilicity and hydrophobicity of the fiber andendows the fiber with certain environmental response. The preparation method comprises the following steps: preparing the polyester fiber matrix having reactive groups on the surface at first; then preparing the particles having reactive functional groups; and finally, mixing the polyester fiber matrix and the particles for a reaction so as to obtain the polyester composite fiber. The polyester composite fiber of the invention can be used for smart textiles, non-woven fabrics, porous films, composite materials and oil-water separators, preferably for smart textiles and oil-water separators.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

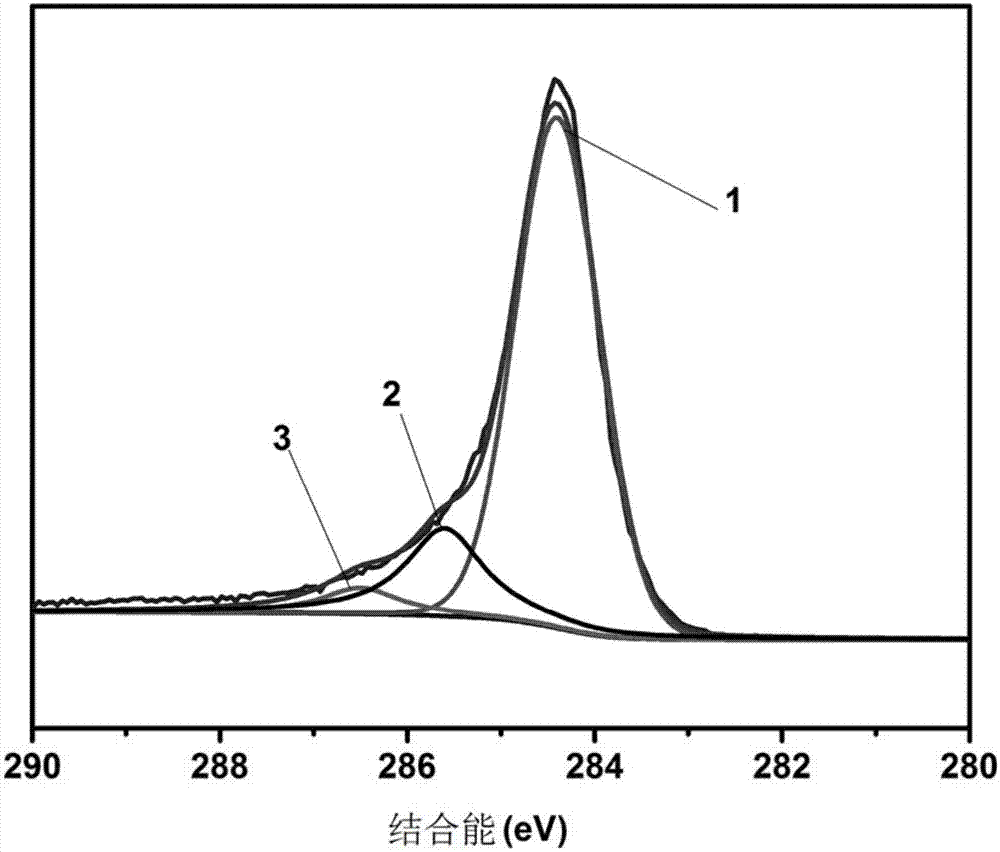

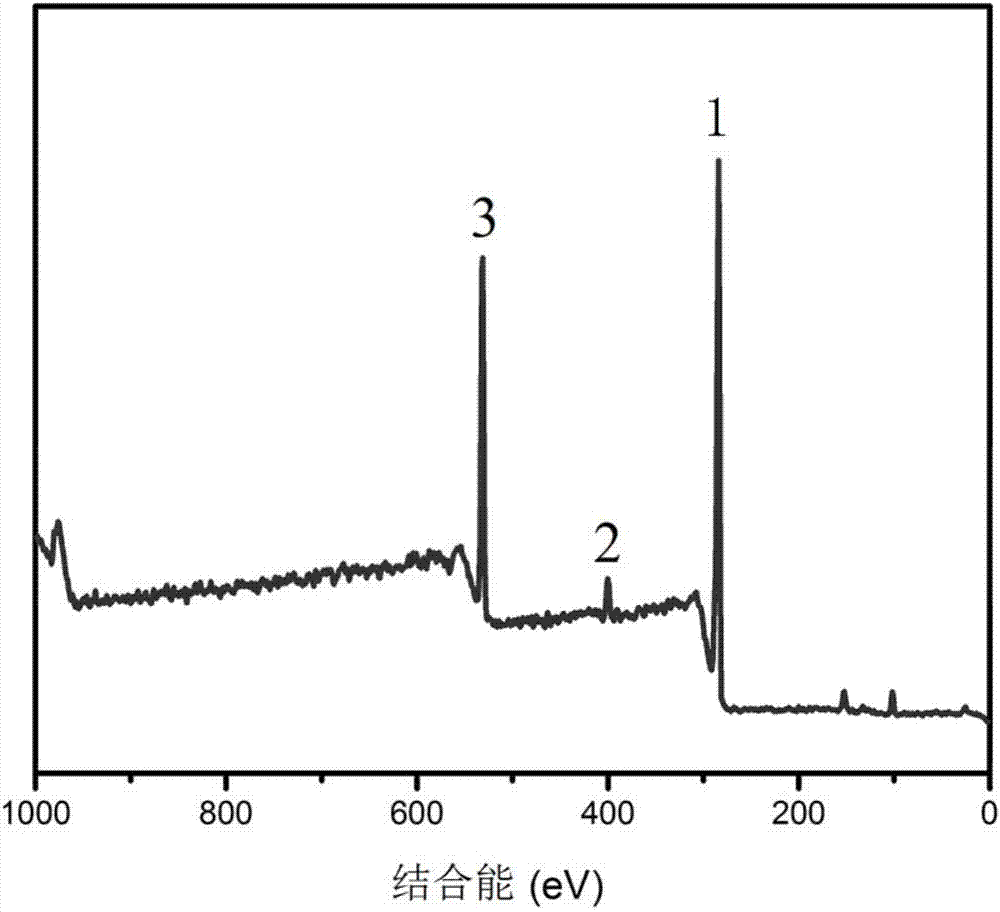

Method for grafting hyperbranched aromatic polyamide to surface of carbon fibers

ActiveCN107313259AImprove application potentialImprove compatibilityCarbon fibresSurface energyPolyamide

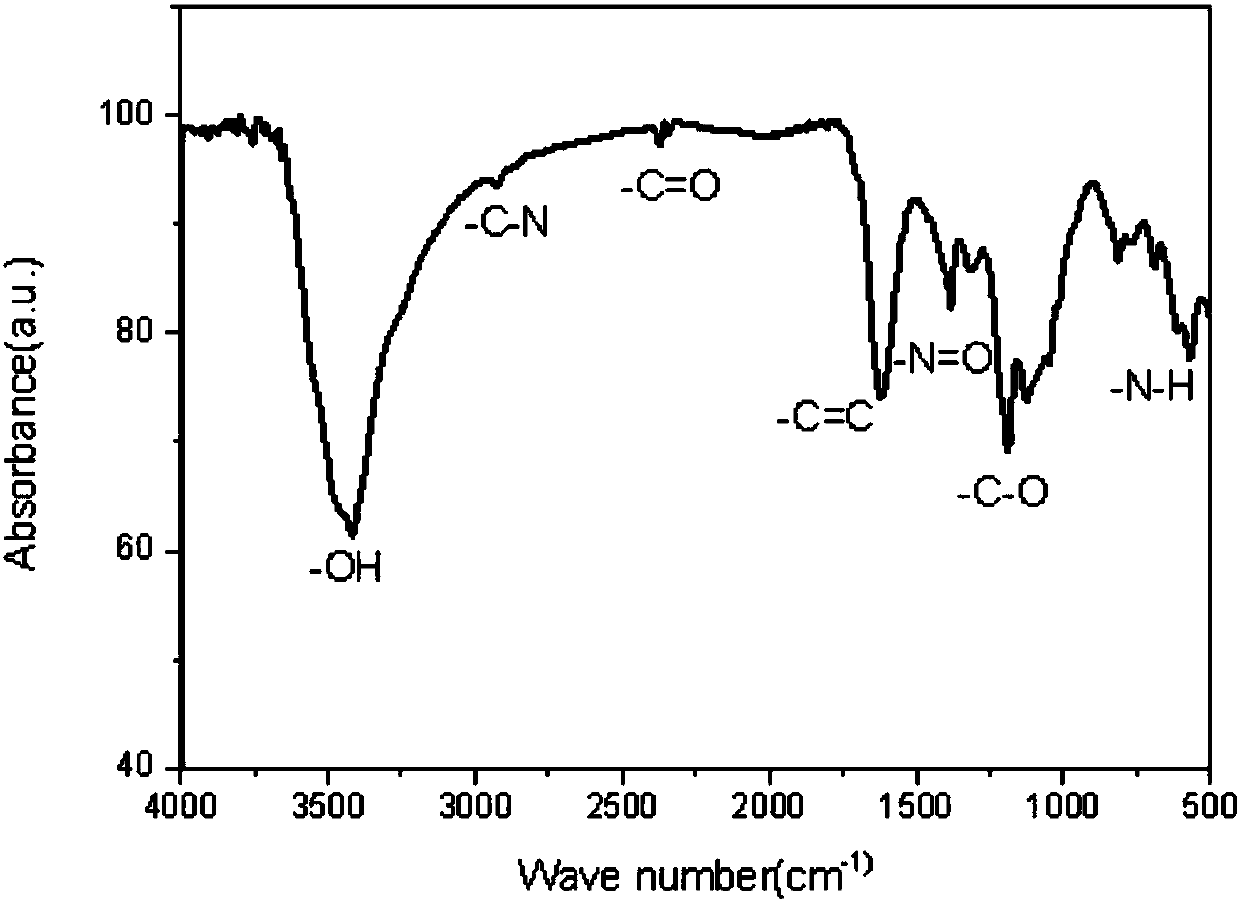

The invention discloses a method for grafting hyperbranched aromatic polyamide to the surfaces of carbon fibers and relates to a method for grafting a polymer to the surfaces of the carbon fibers. The invention aims at solving the problem of low interface bonding strength of an existing carbon fiber composite material. The method comprises the following steps: firstly, carrying out extraction treatment on the carbon fibers; secondly, oxidizing; thirdly, carrying out reducing treatment on the carbon fibers; fourthly, carrying out silanization treatment on the carbon fibers; fifthly, preparing a mixture, and heating to obtain the carbon fibers of which the surfaces are grafted with the hyperbranched aromatic polyamide. Compared with untreated carbon fibers, the carbon fibers of which the surfaces are grafted with the hyperbranched aromatic polyamide, prepared by the method disclosed by the invention, have the advantages that the content of N is increased from original 1.11 percent of the untreated carbon fibers to 2.7 to 4 percent, and surface energy is improved by 100.5 percent or above, and the interfacial shear strength is improved by 65 percent. According to the method disclosed by the invention, the carbon fibers of which the surfaces are grafted with the hyperbranched aromatic polyamide can be obtained.

Owner:QINGDAO UNIV

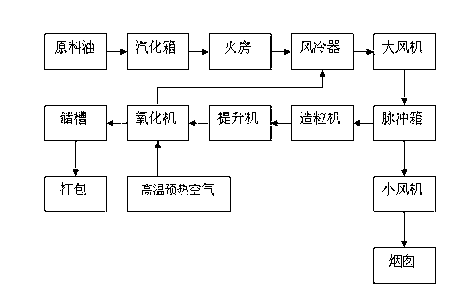

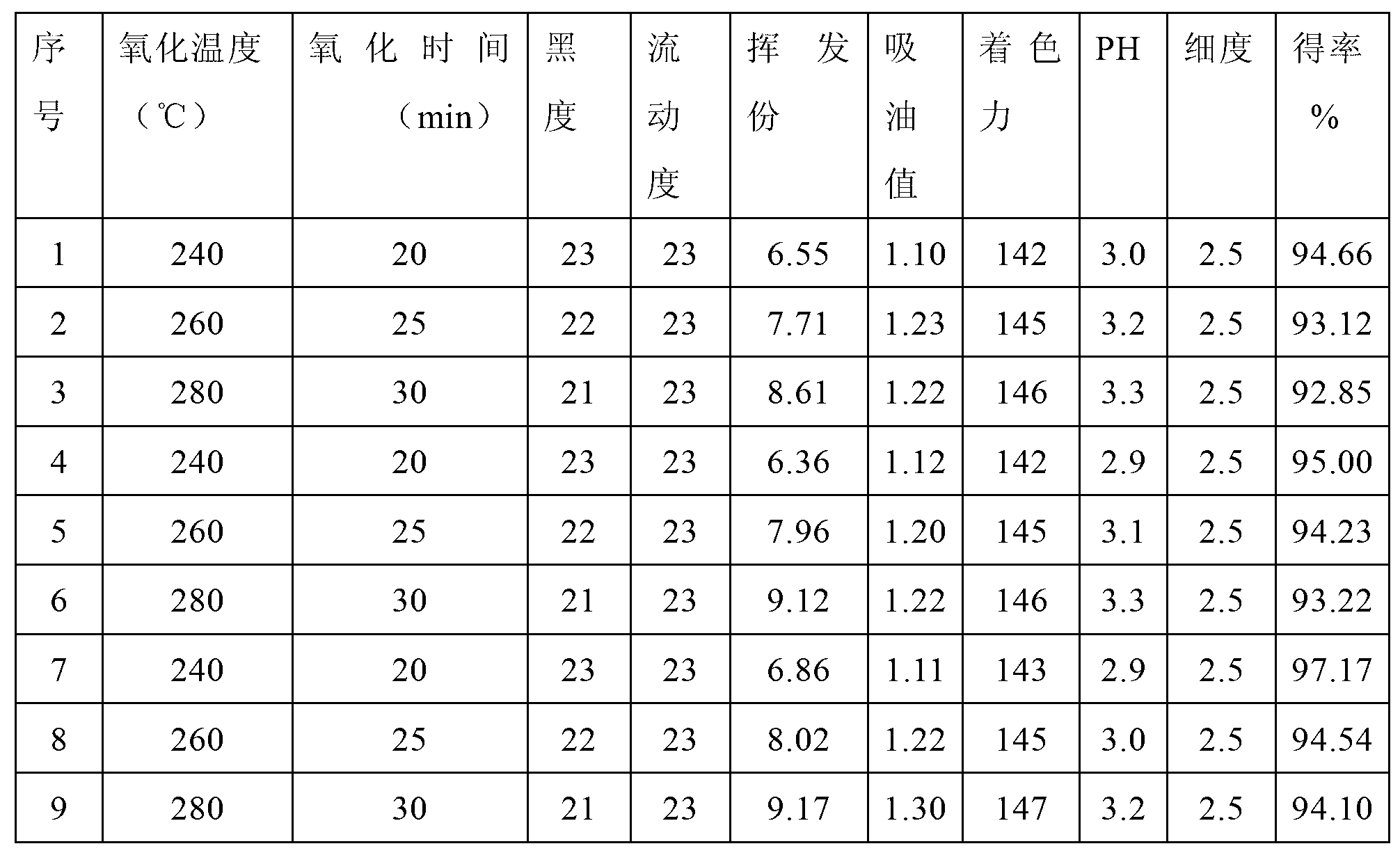

Improved method for producing pigment carbon black

The invention relates to an improved method for producing pigment carbon black. The method comprises the following steps: heating and dehydrating raw oil, conveying the heated raw oil to a vaporizing tank through a pipeline, heating the vaporizing tank so as to vaporize the raw oil, enabling preheated combustible gas to pass through a liquid level of the raw oil in the vaporizing tank so as to mix the oil vapor with the combustible gas, conveying the mixed gas to a carbon black reactor for incomplete combustion and cracking through an oil gas header pipe to produce carbon black, cooling the carbon black and then conveying the cooled carbon black into a pelletizer for pelletizing, performing magnetic separation on the pelletized carbon black, then conveying into an oxidizing machine for performing thermal oxidation treatment, conveying the thermal oxidation-treated carbon black into a cooling tank for cooling to normal temperature, and then conveying to a carbon black storage tank for packaging and storing. The water-soluble pigment carbon black produced by adopting the method is high in volatile matters and dispersity as well as color intensity and low in pH value. The application performances of the pigment carbon black on oil ink, leather, coating, paint and the like can be greatly improved.

Owner:上海焦化化工发展商社

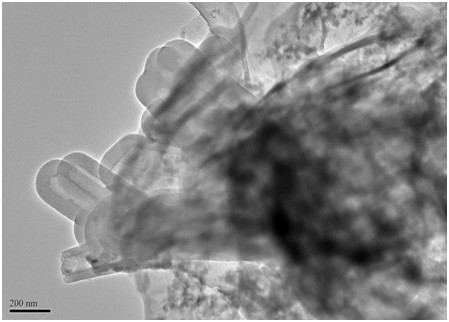

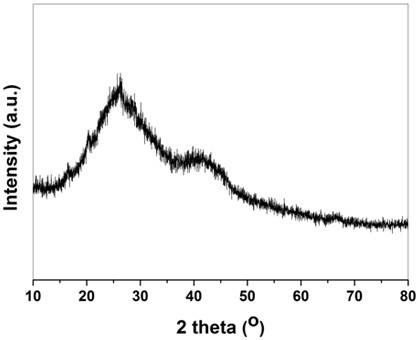

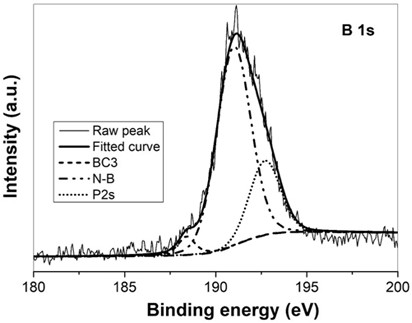

Boron-nitrogen-phosphorus ternary doped metal-free carbon material as well as preparation method and application thereof

InactiveCN111613801AImprove catalytic performanceHigh electrochemical capacitive performanceHybrid capacitor electrodesCell electrodesElectrochemistryPolymerization

The invention belongs to the field of energy materials and electrochemical catalysis and energy storage, and aims to provide a boron-nitrogen-phosphorus ternary doped metal-free carbon material as well as a preparation method and application thereof. The boron-nitrogen-phosphorus ternary doped metal-free carbon material is obtained by taking a phenolic aromatic hydrocarbon compound or a derivativethereof as a carbon source, a phosphorus-containing organic matter or inorganic matter as a phosphorus source, a nitrogen-containing organic matter as a nitrogen source and a boron-containing organicmatter or inorganic matter as a boron source; after sufficient polymerization by a solvothermal method, oxidizing at a low temperature of 100-350 DEG C, and roasting at a high temperature of 600-1200DEG C under the protection of N2 atmosphere. The carbon material is wide in raw material source, and the preparation method is mature in process, is simple to operate, and is convenient for the large-scale production.

Owner:SHANXI UNIV

Carbon-coated ternary cathode material, and preparation method thereof

ActiveCN106571462AAvoid destructionPrevent precipitationCell electrodesCarbon coatedSurface chemical

The invention discloses a carbon-coated ternary cathode material. The chemical formula of the carbon-coated ternary cathode material is LiNi<x>Co<y>Mn<z>O<2>, wherein 0.2<=x<=0.7, 0.1<=y<=0.5, 0.2<=z<=0.3, and x+y+z=1. The outer surface of the carbon-coated ternary cathode material is coated with a carbon carbon network. The invention also provides a preparation method. The carbon-coated ternary cathode material is capable of improving electrode electrical conductivity effectively, improving surface chemical properties of active materials, protecting electrodes from direct contact with electrolyte, and prolonging cycle life.

Owner:湖南裕能新能源电池材料股份有限公司

Method for preparing nanocomposite of MnO2/C/Fe2O3 layer-upon-layer structure

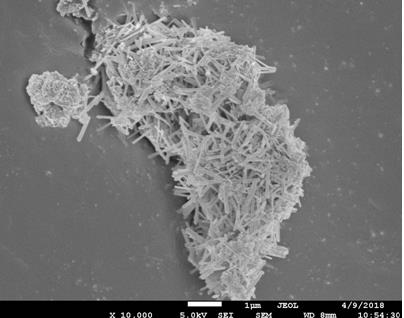

InactiveCN104851597AReduce pollutionThe synthesis process is simpleMaterial nanotechnologyHybrid capacitor electrodesPorous carbonIonic liquid

The invention relates to a method for preparing a nanocomposite compounded by MnO2, porous carbon and Fe2O3 layer upon layer. The composite is a nanocomposite of a layer-upon-layer structure with Fe2O3 being a core, porous carbon being a middle layer and MnO2 being an outer shell. First ferric slat, urea, sugar and ion liquid are used as raw materials, a monodispersed C / Fe2O3 composite is obtained through hydrothermal synthesis in one step, then the C / Fe2O3 is used as the core, potassium permanganate and manganese salt are used as raw materials, and the MnO2 / C / Fe2O3 nanocomposite having the layer-upon-layer structure is obtained through hydrothermal synthesis. The composite is uniform in size, and has broad application prospects as a supercapacitor electrode material.

Owner:BEIJING JIAOTONG UNIV

Nitric acid modified porous carbon and applications thereof

InactiveCN107694515AEasy to prepareEasy to operateOther chemical processesPetroleum wax refiningCarbon sourceHydrothermal synthesis

The invention discloses a nitric acid modified porous carbon and applications thereof. The nitric acid modified porous carbon is prepared by the following steps: taking melamine as the nitrogen sourceand calcium citrate as the carbon source; carrying out one-step hydrothermal synthesis to obtain a precursor; sintering the precursor at a high temperature to obtain N doped porous carbon; and finally subjecting N doped porous carbon to a nitration modification treatment to obtain the nitric acid modified porous carbon, which has the advantages of large specific surface area and abundant porous structure. The porous carbon can be used to adsorb aromatic hydrocarbons in liquid wax oil and the effect is good.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Preparation method of heavy oil hydrodemetallization catalyst

ActiveCN111821993AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetal catalyst

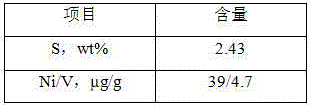

The invention discloses a preparation method of a heavy oil hydrodemetallization catalyst, and the method comprises the following steps: (1) pulverizing a waste hydrotreating catalyst, and roasting; (2) soaking the material obtained in the step (1) into an ammonium bicarbonate aqueous solution, carrying out sealed heat treatment, drying, soaking with a polyethylene glycol solution, and drying to obtain a pretreated material A; (3) performing high-temperature activation treatment on kaolin, then soaking into an ammonium bicarbonate aqueous solution, performing sealed heat treatment, and dryingthe material subjected to heat treatment to obtain a pretreated material B; and (4) kneading and molding pseudo-boehmite, the pretreated material A and the pretreated material B, drying and roasting the molded product to obtain a carrier, and loading a hydrogenation active component onto the carrier to obtain the catalyst. According to the method, the hydrodemetallization catalyst is prepared fromthe waste catalyst and kaolin, environmental pollution is reduced while the production cost is reduced, the content of macropores of the hydrodemetallization catalyst is appropriate, and the hydrodemetallization catalyst has high hydrodemetallization activity and hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

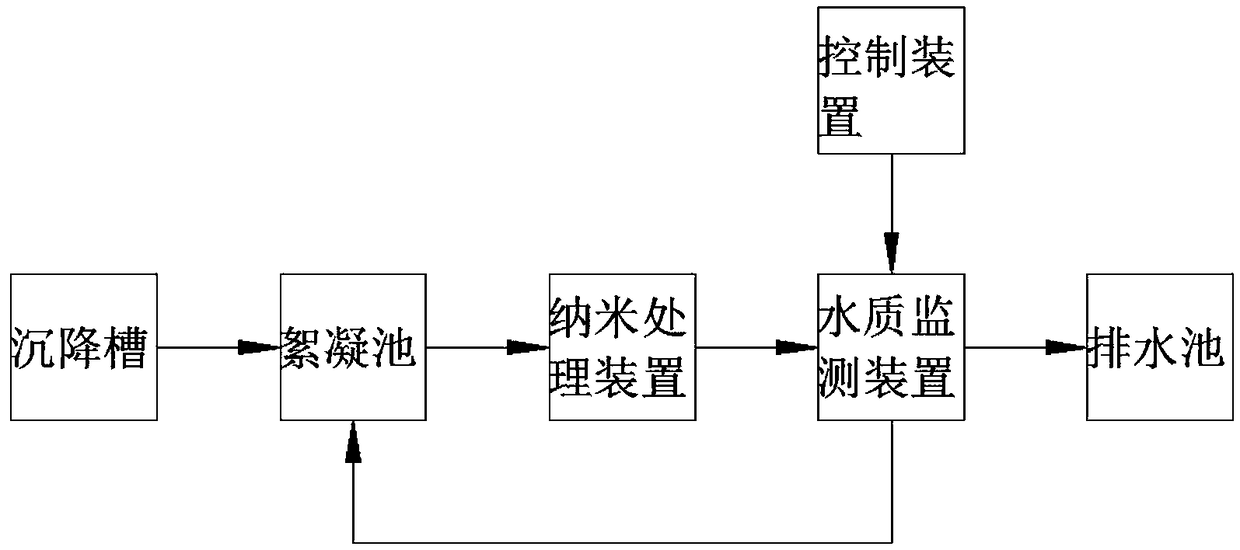

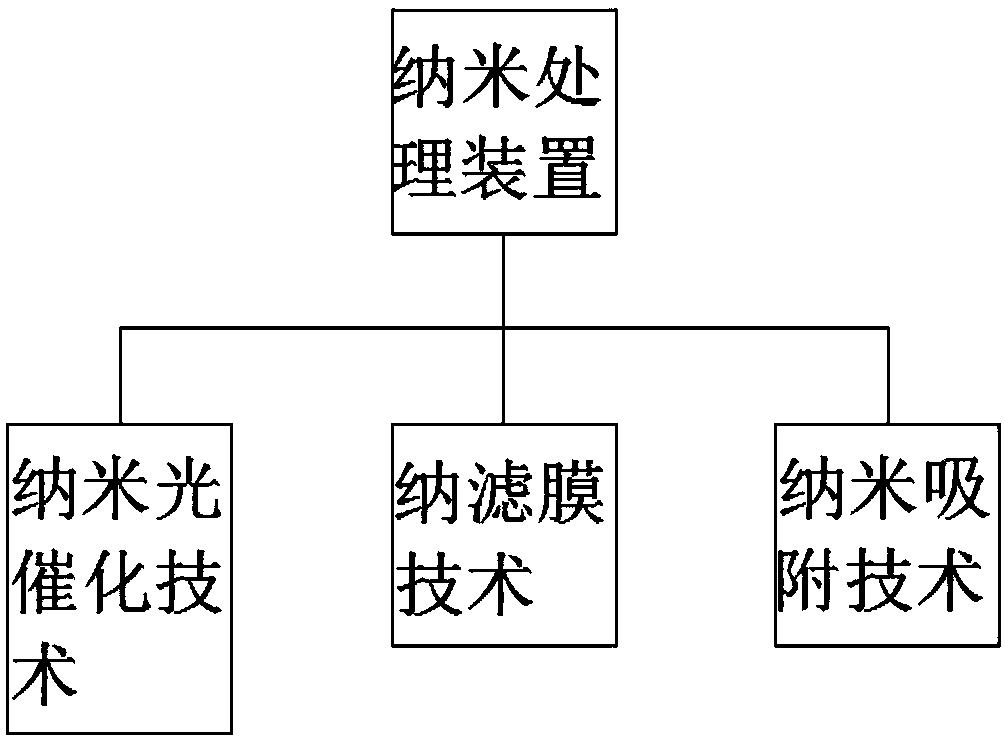

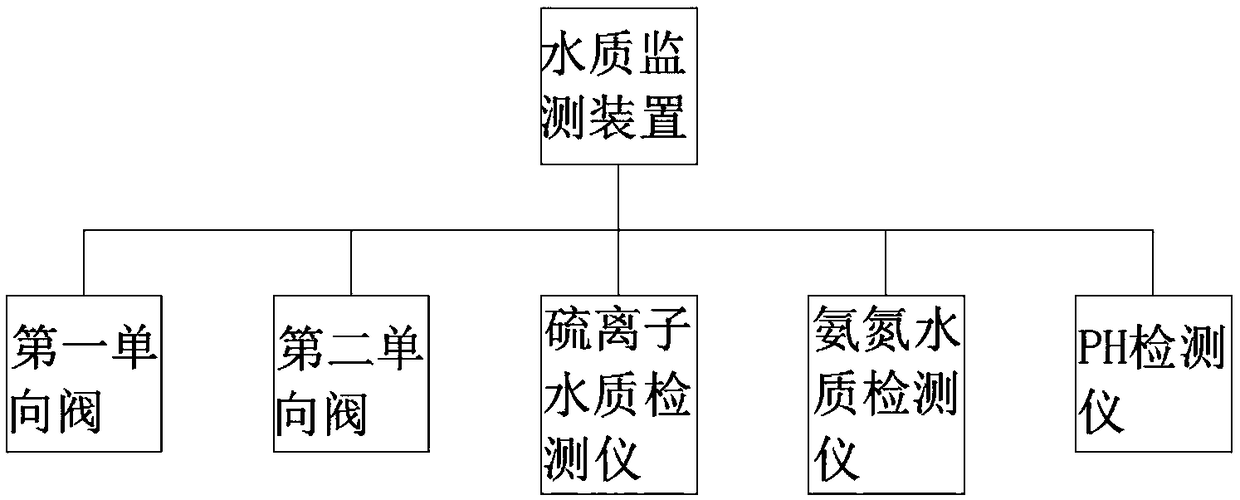

Nanometer water treatment system with water quality monitoring function

InactiveCN108862831AEasy to handleImprove precipitation effectWater treatment parameter controlTreatment by combined electrochemical biological processesAfter treatmentPrecipitation

The invention discloses a nanometer water treatment system with a water quality monitoring function. The nanometer water treatment system comprises a precipitation tank, a flocculation tank, a nanometer treatment device, a water quality monitoring device, a control device and a water drainage tank, wherein the precipitation tank, the flocculation tank, the nanometer treatment device, the water quality monitoring device and the water drainage tank are sequentially communicated through water conveying pipes; the water quality monitoring device is communicated with a flocculation tank box througha water return pipe, and is electrically connected with the control device through a conducting wire; the water quality monitoring device is used for collecting the sewage data after treatment, and sending the sewage data to the control device; the control device is used for comparing the collected sewage data, and sending a sewage drainage or sewage reflux instruction to the water quality monitoring device. The nanometer water treatment system has the advantages that the nanometer treatment device is used for replacing the traditional secondary precipitation technology, and the sewage is strictly monitored by the water quality monitoring device, so that the purifying effect of finally drained water flow is good, and the treatment is thorough; the national drainage standard is completelyreached.

Owner:安徽恒宇环保设备制造股份有限公司

Polyamide composite fibers with intelligent surfaces and preparation method and application of polyamide composite fibers

ActiveCN109989262ASpecial surface structureImprove hydrophilicity and hydrophobicityPhysical treatmentFibre typesFiber matrixWoven fabric

The invention discloses polyamide composite fibers with intelligent surfaces and a preparation method and application of the polyamide composite fibers. The polyamide composite fibers comprise a polyamide fiber matrix and particles which cover the polyamide fiber matrix, so that the roughness of the fibers can be improved by covering the surface of the fiber matrix with the particles, the hydrophobicity of the fibers is further improved, and the condition of poor dimensional stability caused by strong hygroscopicity of the polyamide fibers is improved. The preparation is carried out as follows: firstly, obtaining a polyamide fiber matrix with reactive groups on the surface; secondly, obtaining particles with reactive functional groups; and finally, mixing and reacting the polyamide fiber matrix and the particles to obtain the polyamide composite fibers. The polyamide composite fibers can be used for intelligent textiles, non-woven fabrics, porous films, composite materials and oil-water separators, and is preferably used for intelligent textiles and oil-water separators.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Polyolefin composite material with intelligent surface, and preparation method and application thereof

InactiveCN109385894ASpecial surface structureImprove hydrophilicity and hydrophobicityFibre typesPolyolefinPolymer science

The invention discloses a polyolefin composite material with an intelligent surface, and a preparation method and application thereof. The polyolefin composite material comprises a polyolefin matrix and particles covering the polyolefin matrix, wherein the particles and the polyolefin matrix are chemically bonded; preferably, the particles are polymer particles; more preferably, the particles arepolymer particles with environmental response; thus, covering of the surface of the polyolefin matrix with the particles can improve the hydrophilicity and hydrophobicity of the material and endows the material with certain environmental response. The preparation method comprises the following steps: preparing the polyolefin matrix having reactive groups on the surface at first; then preparing theparticles having reactive functional groups; and finally, mixing the polyolefin matrix and the particles for a reaction so as to obtain the polyolefin composite material. The polyolefin composite material of the invention can be used for smart textiles, non-woven fabrics, porous films, waterproof gas-permeable membranes, battery diaphragms, composite materials, and switch films.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Improved method for extracting meilingmycin from nanchang streptomycete fermenting liquor

InactiveCN1394868AGuaranteed qualityImprove filter characteristicsSugar derivativesStreptomyces nanchangensisSolvent

The improved method for extracting melingmycin from Nanchang streptomycete fermented liquor is mainly formed from the following steps: pretreatment process of fermented liquor, liquid-solid separation process, extracting melingmycin from residual filtrate and recovering process, pretreatment process of filter cake (mycelium), further solvent leaching of mycelium and concentration process of leaching liquor and one-step extraction process of concentrated leaching liquor. The total recovery rate of melingmycin can be up to above 85%.

Owner:EAST CHINA UNIV OF SCI & TECH

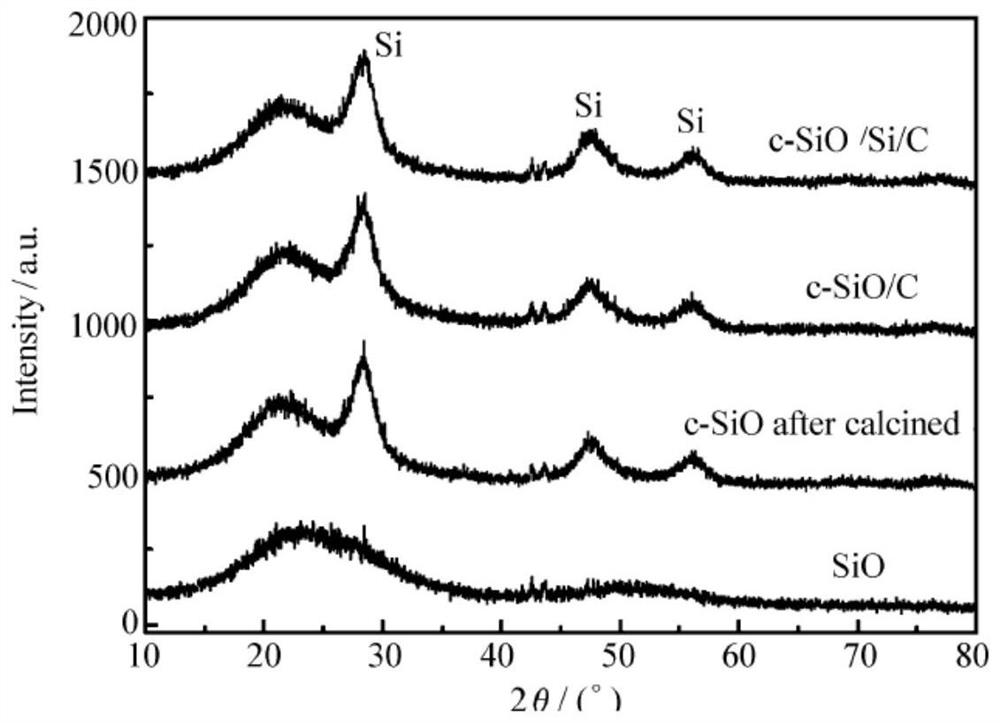

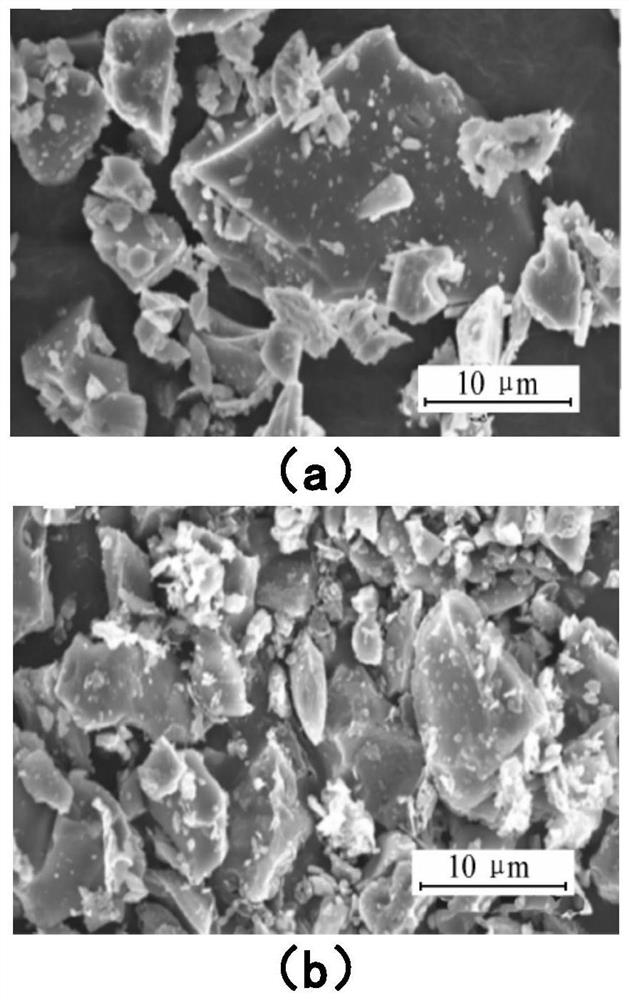

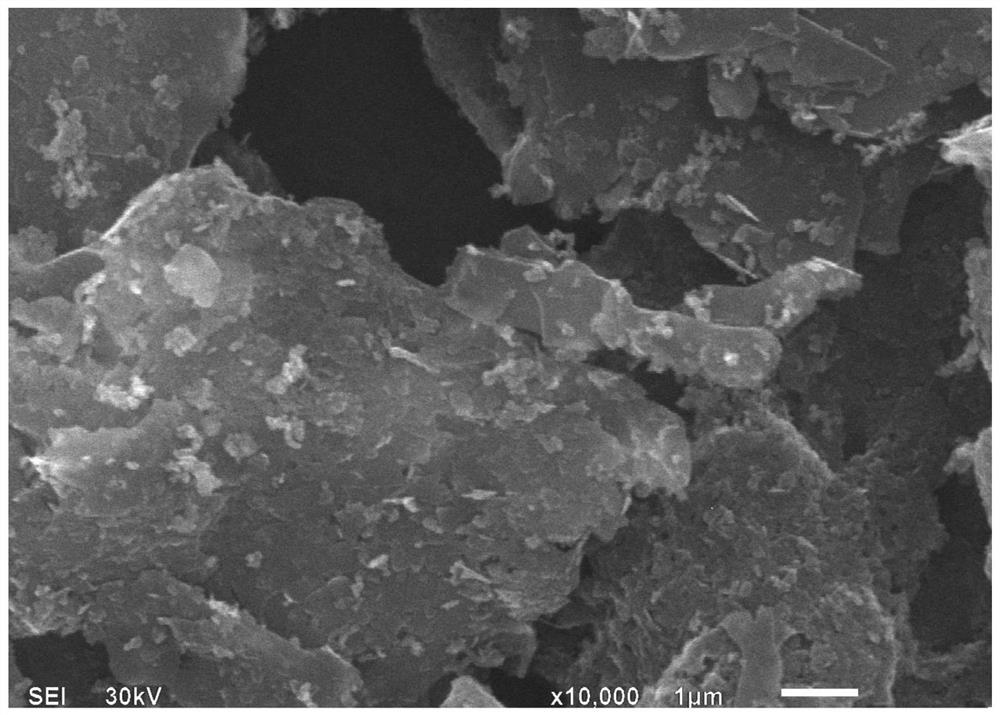

Preparation method of silicon carbon negative electrode material, silicon carbon negative electrode material and lithium ion battery

ActiveCN107565115BWide variety of sourcesLow costCell electrodesSecondary cellsSilicon monoxideSilicon oxide

The invention belongs to the technical field of a lithium ion battery, and relates to a silicon carbon negative electrode material and a preparation method therefor, and the lithium ion battery. The preparation method for the silicon carbon negative electrode material comprises the following steps of (a), by taking silicon monoxide as the substrate material, performing heating treatment on siliconmonoxide to enable silicon monoxide to be subjected to a disproportionation reaction to generate c-SiO; (b), putting c-SiO into a chemical vapor deposition furnace, heating in protective atmosphere until a reaction temperature is reached, and pumping a carbon source to be subjected to a vapor deposition reaction to obtain c-SiO / C, wherein the carbon source is a liquid-state or solid-state compound; and (c), performing corrosion of the c-SiO / C by a corrosive liquid to obtain the silicon carbon negative electrode material c-SiO / Si / C. The preparation method is simple in process and easy to operate; and the prepared silicon carbon negative electrode material has the high lithium storage characteristic as the silicon type material and the high cycling stability as the carbon type material, aswell as high specific capacity, high conductivity and high cycling performance.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

Carbon-coated ternary positive electrode material and preparation method thereof

InactiveCN112349897AImprove conductivityImprove surface chemistrySecondary cellsPositive electrodesElectrical batteryLithium electrode

The invention discloses a carbon-coated ternary positive electrode material which comprises a ternary positive electrode material, the ternary positive electrode material is LinNi1-x-yCoxMnyO2, x is more than 0 and less than 0.5, y is more than 0 and less than 0.5, and n is more than 0.9 and less than 1.5; the invention also provides a preparation method of the carbon-coated ternary positive electrode material, the method can improve the electronic conductivity of the carbon-coated layer, and the material shows excellent electrochemical performance when being used as the positive electrode material of the lithium ion battery; the carbon material has the advantages of excellent electrical conductivity, ultrahigh chemical and electrochemical stability, unique physical properties, low cost and the like, the problem of poor electrical conductivity of the carbon-coated lithium ion positive electrode material can be improved by adopting the carbon-coated lithium ion positive electrode material, the electrical conductivity of the carbon material can be effectively improved, and the electrical conductivity of the carbon-coated ternary positive electrode material is further improved; and furthermore, the electrochemical performance of the positive electrode material is improved.

Owner:SHANDONG FENGYUAN CHEM CO LTD

Glycosaminoglycan and synthetic polymer materials for blood-contacting applications

ActiveUS20180305528A1Improve surface chemistryFeasible at commercial productionLow-density polyethyleneLinear low-density polyethylene

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

A kind of carbon/silicon/carbon composite material and its preparation method and application

ActiveCN108172785BMake up for the problem of poor conductivityImprove cycle performanceCell electrodesCarbon compositesCarbon layer

The invention relates to a carbon / silicon / carbon composite material and preparation method and application thereof. The composite material takes a carbon material as a core, and a nanometer silicon layer and a nanometer carbon layer wrap a surface of the carbon material. According to the preparation method of the carbon / silicon / carbon composite material, a silicon oxide layer is coated on the surface of the carbon material by a mode of absorbing organosilane with microwave, the preparation period is greatly shortened, and the production efficiency is improved; a silicon oxide is reduced to silicon by mechanical ball-grinding of nanometer metal particles with high reduction performance under a room temperature, and the energy consumption is reduced; and a carbon layer is coated on a siliconlayer by high-temperature roasting to obtain the carbon / silicon / carbon composite material. During the charge-discharge process of the carbon / silicon / carbon composite material, the volume change of asilicon electrode material can be effectively controlled, the electrode structure is maintained complete, and the carbon / silicon / carbon composite material is large in cycle capacity and long in service lifetime and has wide application market.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Dewaxing liquid for LED (light-emitting diode) manufacturing process

PendingCN114806726AImprove solubilityExtended service lifeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic solventAdhesive

The invention discloses a dewaxing liquid for an LED (light-emitting diode) manufacturing process, belongs to the field of wet electronic chemicals, and is mainly applied to semiconductor wafer manufacturing. Through optimal combination of the specific anionic surfactant, the organic solvent, the cosolvent and the latent solvent, the dewaxing liquid greatly reduces the surface tension of a system, has outstanding permeation and dispersion performance, meanwhile, has relatively strong temperature resistance, low cost and high dewaxing efficiency, can also meet process requirements at relatively low working temperature, and is suitable for industrial production. The adhesive has the advantages of high solubility to bonding wax, long service life and environment-friendly material composition, and can meet the technological requirements of LED (light-emitting diode) manufacture procedures.

Owner:福建省佑达环保材料有限公司

A kind of polyamide composite fiber with intelligent surface and its preparation method and application

ActiveCN109989262BSpecial surface structureImprove hydrophilicity and hydrophobicityPhysical treatmentFibre typesPolymer sciencePorous membrane

The invention discloses a polyamide composite fiber with an intelligent surface and its preparation method and application. The polyamide composite fiber includes a polyamide fiber matrix and particles covering it. In this way, covering the particle on the surface of the fiber matrix can improve fiber The roughness, and then improve the hydrophilic and hydrophobic properties of the fibers, so that the poor dimensional stability of polyamide fibers caused by strong hygroscopicity is improved. The preparation is carried out as follows: first obtain the polyamide fiber matrix with reactive groups on the surface, then obtain particles with reactive functional groups, and finally mix the polyamide fiber matrix with the particles for reaction to obtain the polyamide composite fiber. The polyamide composite fiber of the present invention can be used in smart textiles, non-woven fabrics, porous membranes, composite materials and oil-water separators, preferably smart textiles and oil-water separators.

Owner:BEIJING INST OF CLOTHING TECH

Preparation method of PLA modified material

PendingCN113354931AImprove surface chemistryImprove anti-corrosion performanceActivated carbonPolyamide

The invention discloses a preparation method of a PLA modified material. The method comprises the following steps: S1, preparing the following raw materials in parts by mass: 22 to 30 parts of PLA, 22 to 26 parts of polyamide resin, 19 to 21 parts of carbon fiber, 13 to 17 parts of sodium perborate, 11 to 15 parts of montmorillonite, 12 to 14 parts of diphenylmethane diisocyanate, 9 to 14 parts of activated carbon, 9 to 14 parts of modified nano titanium dioxide, 8 to 10 parts of polyol, 6 to 10 parts of polyvinyl alcohol, 3 to 7 parts of an ultraviolet light absorber, 3-7 parts of a flame retardant, 2-6 parts of a plasticizer, 1-3 parts of an antibacterial agent and 0.5-2 parts of an initiator; and S2, adding the PLA, the polyamide resin, the montmorillonite, the diphenylmethane diisocyanate and the polyvinyl alcohol in the step S1 into an ultrasonic dispersion machine. The flame-retardant rubber has the advantages of excellent flame-retardant effect, high tensile strength and wear resistance, long service cycle and environmental friendliness.

Owner:福建凯基高分子材料股份有限公司

A kind of carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN106571462BAvoid destructionPrevent precipitationCell electrodesCarbon coatedSurface chemical

The invention discloses a carbon-coated ternary cathode material. The chemical formula of the carbon-coated ternary cathode material is LiNi<x>Co<y>Mn<z>O<2>, wherein 0.2<=x<=0.7, 0.1<=y<=0.5, 0.2<=z<=0.3, and x+y+z=1. The outer surface of the carbon-coated ternary cathode material is coated with a carbon carbon network. The invention also provides a preparation method. The carbon-coated ternary cathode material is capable of improving electrode electrical conductivity effectively, improving surface chemical properties of active materials, protecting electrodes from direct contact with electrolyte, and prolonging cycle life.

Owner:湖南裕能新能源电池材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com