Boron-nitrogen-phosphorus ternary doped metal-free carbon material as well as preparation method and application thereof

A metal-free, carbon-free technology, applied in the preparation/purification of carbon, electrical components, battery electrodes, etc., can solve the problem that the research on the capacitance performance of ternary doped carbon materials has not yet been reported, and achieve the improvement of catalytic performance and electrochemical performance. Capacitance performance, good electrochemical capacitance performance, the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

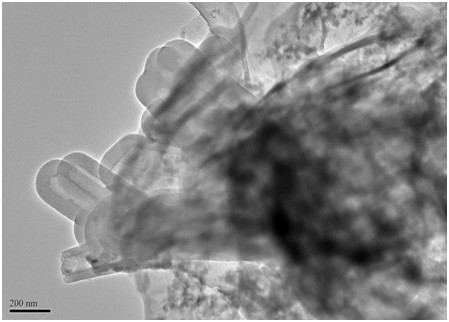

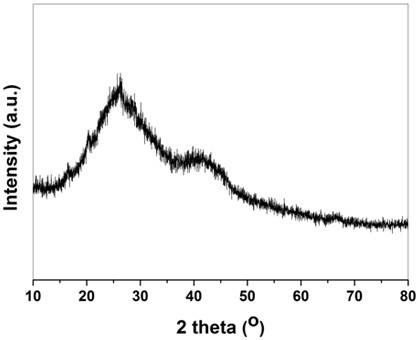

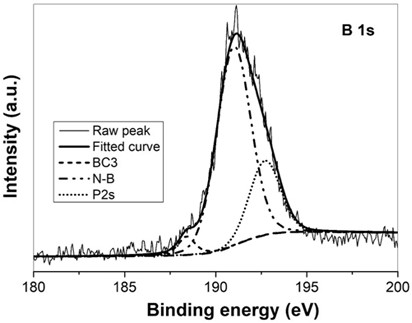

[0044] Put 15.33mmol of phenol, 2.18mmol of hexachlorotrimeric phosphazene, 10.19mmol of formaldehyde, 4.10mmol of melamine and 2.35mmol of boric acid into a conical flask in sequence, add 6mL of distilled water and 28mL of ethanol, stir well at 50°C, and react for 24h; React in a hydrothermal kettle at 115°C for 24 hours; continue to raise the temperature to 200°C at a rate of 10°C / min in the oxidation furnace and keep the temperature for 5 hours and then drop to room temperature; The heating rate was raised to 600°C and kept at a constant temperature for 3 hours; after cooling down, the sample was taken out, washed 3-5 times with deionized water, and dried to obtain a boron-nitrogen-phosphorus ternary doped metal-free carbon material, numbered BNPC-1. The appearance of the obtained carbon material is black powder, and it is tested by ICP-AES (inductively coupled atomic emission spectrometer) and N 2 The composition and specific surface area of the carbon material were anal...

Embodiment 2

[0046] Put 16.27mmol hydroquinone, 3.61mmol hexamethylphosphoric triamide, 15.44mmol formaldehyde, 4.66mmol melamine and 4.28mmol boric acid in sequence in a conical flask, add 6mL distilled water and 28mL ethanol, stir fully at 50°C, and react for 18h; React in a hydrothermal kettle at 115°C for 20 hours; continue to heat up to 200°C in an oxidation furnace at a rate of 5°C / min and keep the temperature for 6 hours and then drop to room temperature; The heating rate per minute was raised to 800°C and kept at a constant temperature for 3 hours; after cooling down, the sample was taken out, washed 3-5 times with deionized water, and dried to obtain a boron-nitrogen-phosphorus ternary doped metal-free carbon material, numbered BNPC-2. The appearance of the obtained carbon material is black powder, and it is tested by ICP-AES (inductively coupled atomic emission spectrometer) and N 2 The composition and specific surface area of the carbon material were analyzed by adsorption and...

Embodiment 3

[0048] Put 15.33mmol of aminophenol, 6.88mmol of sodium dihydrogen phosphate, 15.12mmol of formaldehyde, 6.01mmol of melamine and 3.61mmol of boron chloride into a conical flask in sequence, add 34mL of chloroform, stir thoroughly at 80°C, and react for 10h; React in the kettle at 180°C for 12h; continue to heat up to 180°C in the oxidation furnace at a rate of 1°C / min and keep the temperature for 8h and then drop to room temperature; The heating rate was increased to 900°C and the temperature was kept constant for 2 hours; after cooling down, the sample was taken out, washed 3-5 times with deionized water, and dried to obtain a boron-nitrogen-phosphorous ternary doped metal-free carbon material, numbered BNPC-3. The appearance of the obtained carbon material is black powder, and it is tested by ICP-AES (inductively coupled atomic emission spectrometer) and N 2 The composition and specific surface area of the carbon material were analyzed by adsorption and desorption tests. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com