Method for preparing nanocomposite of MnO2/C/Fe2O3 layer-upon-layer structure

A nano-composite material, fe2o3 technology, applied in the field of nano-composite material preparation, can solve problems such as poor electrical conductivity, achieve the effects of inhibiting agglomeration, less environmental pollution, and improving surface chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh ferric salt, urea, glucose, and 1-butyl-3-methylimidazolium tetrafluoroborate in a molar ratio of 1:5:1:0.1, mix them in 60ml deionized water, stir evenly, and transfer to 100ml In a high-pressure reactor, react at 90°C for 1h. The product obtained from the reaction was calcined at 250 °C for 1 h in an Ar atmosphere to obtain C / Fe 2 o 3 Structured nanocomposites.

[0027] Get the C / Fe prepared by the above steps 2 o 3 , ultrasonically dispersed in the aqueous solution, and then introduced potassium permanganate and manganese chloride according to the molar ratio of 1:1, stirred and mixed evenly, transferred to a 100ml autoclave, and reacted at 120°C for 3h. The product obtained from the reaction was filtered, washed, and dried to obtain MnO 2 / C / Fe 2 o 3 Layer-by-layer nanocomposites.

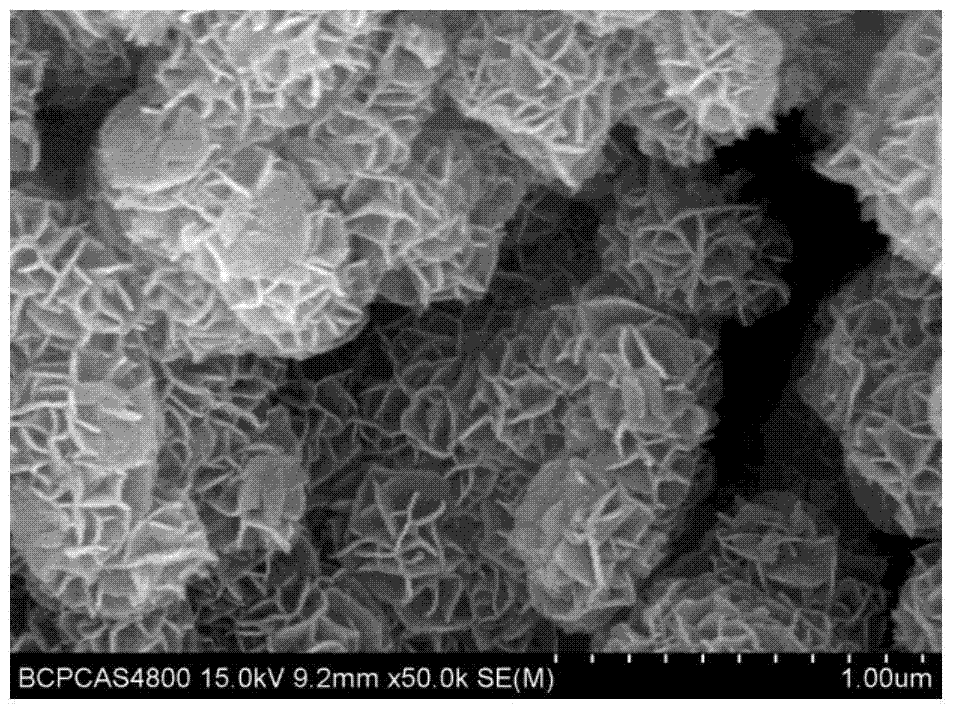

[0028] The morphology of the obtained nanocomposite is as follows figure 1 , it can be observed from the figure that the MnO 2 / C / Fe 2 o 3 The nanocomposite has a petal...

Embodiment 2

[0031] Weigh ferric chloride, urea, fructose, and N-ethylpyridine tetrafluoroborate in a molar ratio of 1:30:30:10, mix them in 60ml of deionized water, stir evenly, transfer to a 100ml high-pressure reactor, 200 ℃ reaction 48h. The product obtained from the reaction was calcined at 700 °C for 24 h in an Ar atmosphere to obtain C / Fe 2 o 3 Structured nanocomposites.

[0032] Get the C / Fe prepared by the above steps 2 o 3 , ultrasonically dispersed in the aqueous solution, and then introduced potassium permanganate and manganese sulfate according to the molar ratio of 1:0.1, stirred and mixed evenly, transferred to a 100ml high-pressure reactor, and reacted at 200°C for 60h. The product obtained from the reaction was filtered, washed, and dried to obtain MnO 2 / C / Fe 2 o 3 Layer-by-layer nanocomposites.

Embodiment 3

[0034] Weigh iron sulfate, urea, maltose, and 1-ethyl-3-methylimidazolium tetrafluoroborate in a molar ratio of 1:15:15:5, mix them in 60ml deionized water, stir evenly, and transfer to 100ml high-pressure reaction In the kettle, react at 150°C for 24h. The product obtained from the reaction was calcined at 450 °C for 12 h in an Ar atmosphere to obtain C / Fe 2 o 3 Structured nanocomposites.

[0035] Get the C / Fe prepared by the above steps 2 o 3 , ultrasonically dispersed in an aqueous solution, and then introduced potassium permanganate and manganese acetate according to a molar ratio of 1:0.5, stirred and mixed evenly, transferred to a 100ml high-pressure reactor, and reacted at 150°C for 30h. The product obtained from the reaction was filtered, washed, and dried to obtain MnO 2 / C / Fe 2 o 3 Layer-by-layer nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com