Polyolefin composite material with intelligent surface, and preparation method and application thereof

A composite material, polyolefin technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of affecting the function of functional substances and the weak bonding surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

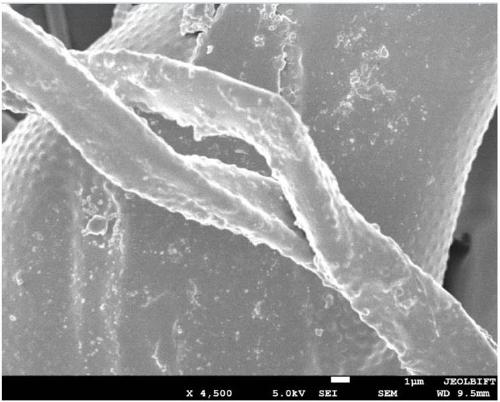

[0021] According to a preferred embodiment of the present invention, the particles are connected to the polyolefin matrix through ester bonds, amide bonds, ether bonds, C=N bonds, N-N bonds, C-C bonds, C=C bonds, S-S bonds, C-S bonds And / or S-O bonding.

[0022] In a further preferred embodiment, the particles are bonded to the polyolefin matrix through ester bonds, amide bonds, ether bonds, C=N bonds, S-S bonds and / or C-S bonds.

[0023] In a further preferred embodiment, the particles are bonded to the polyolefin matrix through ester bonds, amide bonds and / or ether bonds.

[0024] Wherein, the particles are combined with the polyolefin matrix through chemical bonds, so that the material of the present invention has a very stable structure compared with simple blending or bonding through adhesive action.

[0025] In the present invention, the particles on the surface of the polyolefin composite material did not fall off after the polyolefin composite material was washed by u...

Embodiment 1

[0113] For the preparation of poly(N-isopropylacrylamide) particles containing epoxy groups in Example 1, refer to Document 1 (Penghui Li et al., Colloid Surface B 2013, 101, 251-255.);

Embodiment 2

[0114] For the preparation of poly(acrylic acid-styrene) particles in Example 2, refer to Document 2 (Xinlong Fan, etal. Polym. Chem., 2015, 6, 703-713);

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com