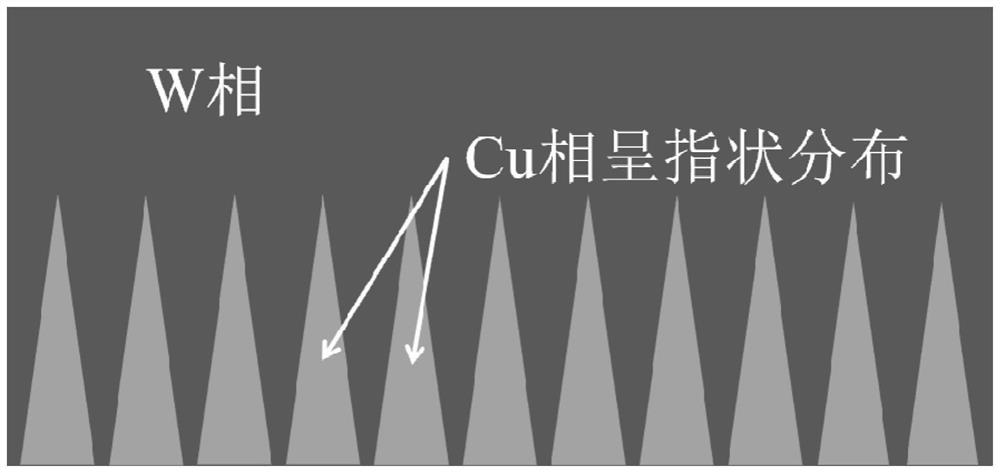

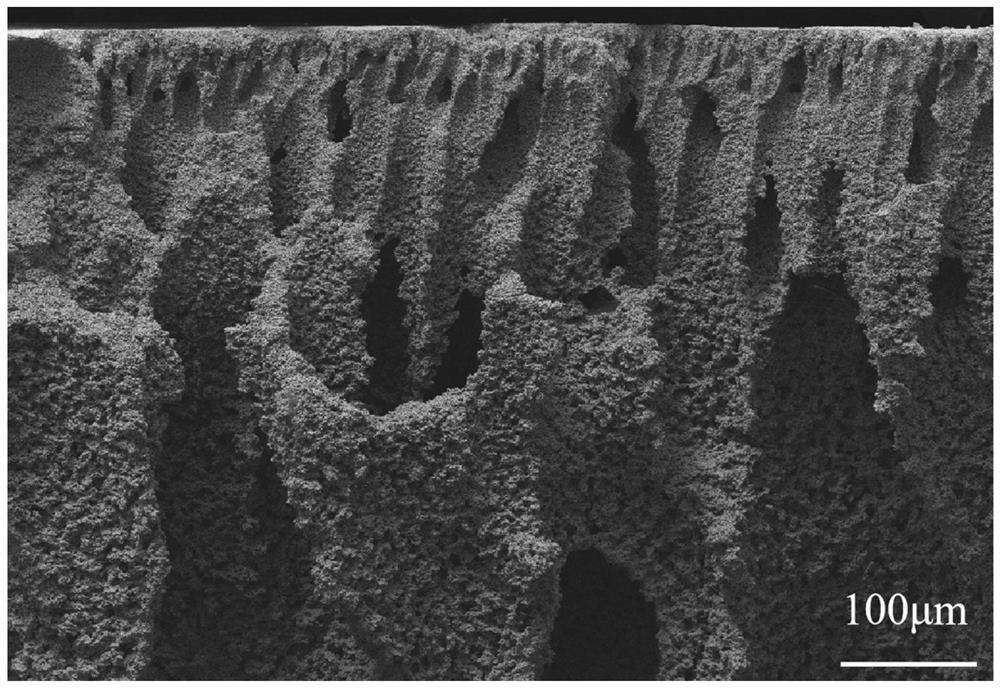

A kind of preparation method of w-cu composite plate with cu phase in finger-like gradient distribution

A technology of gradient distribution and composite board, which is applied in the field of preparation of W-Cu composite board, can solve the problems of less research and achieve the effect of simple process, good sintering activity and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

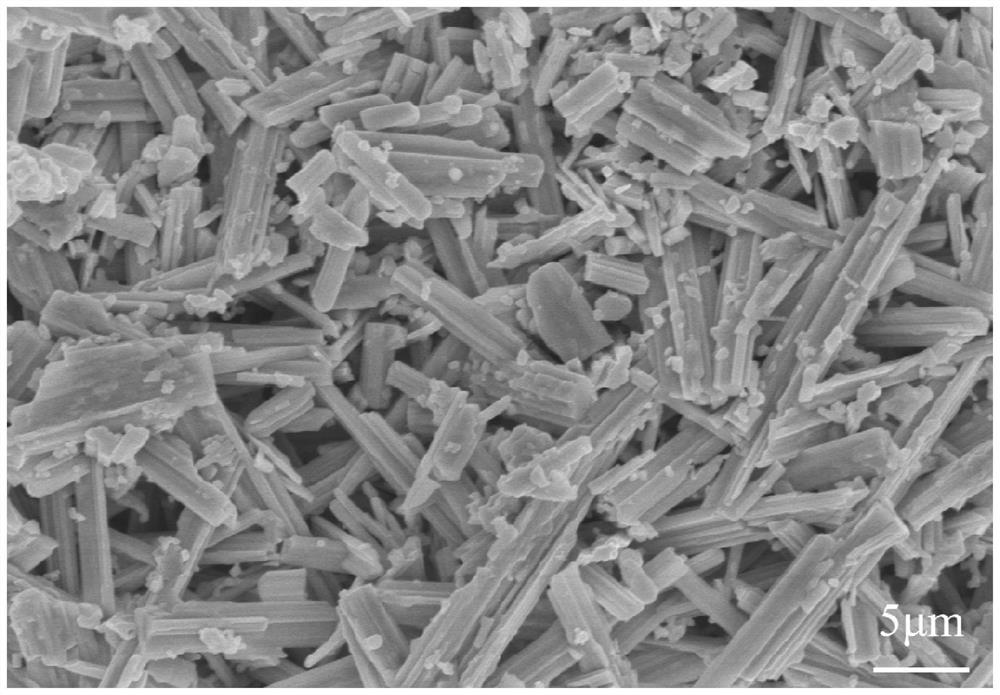

[0033] (1) After mixing ammonium metatungstate, ammonium nitrate, glycine and ethylenediaminetetraacetic acid, add deionized water to disperse, and then put it into a muffle furnace under an air atmosphere at 200 °C for constant temperature combustion for 2 hours to obtain WO X Powder; mass ratio of ammonium metatungstate, ammonium nitrate, glycine, EDTA and deionized water 12:19.2:7:0.7:50. figure 2 for the income WO X From the SEM photograph of the powder, it can be seen that the obtained powder is in the shape of a short rod, with a diameter of 0.5-2 μm and a length of 2-10 μm.

[0034] Weigh WO X50g of powder, 100g of 0.8μm W powder, 4g of polyethersulfone, 2.67g of polyvinylpyrrolidone, and 26.7g of N-methylpyrrolidone were added together into a ball milling tank, the ratio of ball to material was 1:5, and the ball was milled for 12 hours at a speed of 400 r / min to obtain Slurry with a solids content of 82%.

[0035] (2) the obtained slurry is casted on the PET film t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com