An aluminum alloy coupled bionic self-cleaning surface and its preparation method

An aluminum alloy, self-cleaning technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as complicated preparation methods, inconvenient operation, and environmental pollution, and achieve good hydrophobicity, improved controllability, and low viscosity The effect that goes along with the self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

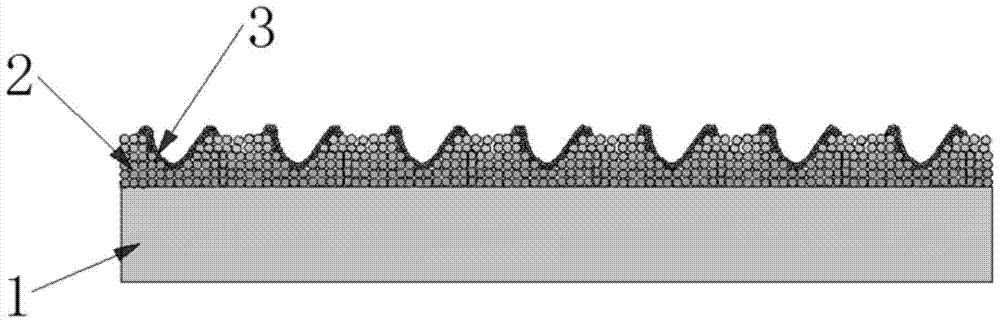

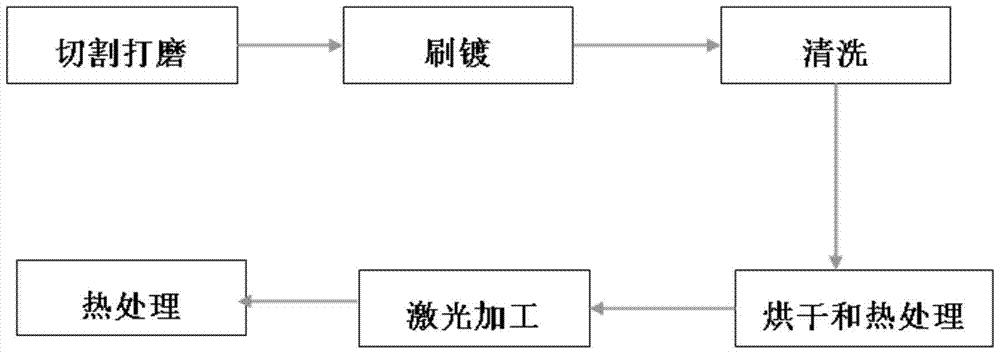

[0025] like figure 2 Shown, a kind of its preparation method of aluminum alloy coupling biomimetic self-cleaning surface, this method comprises the following steps:

[0026] Step 1: Cut the substrate wire into the required size, and polish the surface of the substrate with 600 mesh, 800 mesh and 1500 mesh sandpaper to make the surface relatively smooth.

[0027] Step 2: Brush-plating the pre-grinded substrate: the plating solution used for brush-plating is ultra-fast nickel, and the main component is: NiSO 4 .6H 2 O (265g / L), triammonium citrate (55g / L), ammonia water (105g / L) and ammonium acetate (23g / L); the pH of the plating solution is about 7.5; the brush plating voltage is 8V DC, and the plating pen and The relative speed of the substrate is controlled at 8-12m / min, the brush-plating temperature is controlled at 15°C-35°C, and the surface brush-plating time is selected as 10min.

[0028] Step 3: The brush-plated substrate is ultrasonically cleaned in acetone to preve...

Embodiment 2

[0033] Step 1 and Step 4 to Step 6, the above steps are completely the same as the corresponding steps in Example 1, the difference is that in Step 2, the brush plating voltage is 10V DC.

Embodiment 3

[0035] Step 1 and Step 4 to Step 6, the above steps are completely the same as the corresponding steps in Embodiment 1, the difference is that in Step 2, the brush plating voltage is 12V DC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com