Pharmacy wastewater preprocessing system, method, and catalyst

A pharmaceutical wastewater, pretreatment technology, applied in water/sewage treatment, natural water treatment, special compound water treatment, etc., can solve problems such as no good solution, to improve hydroxyl utilization efficiency, strong impact resistance, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 is used for the system of pharmaceutical wastewater pretreatment

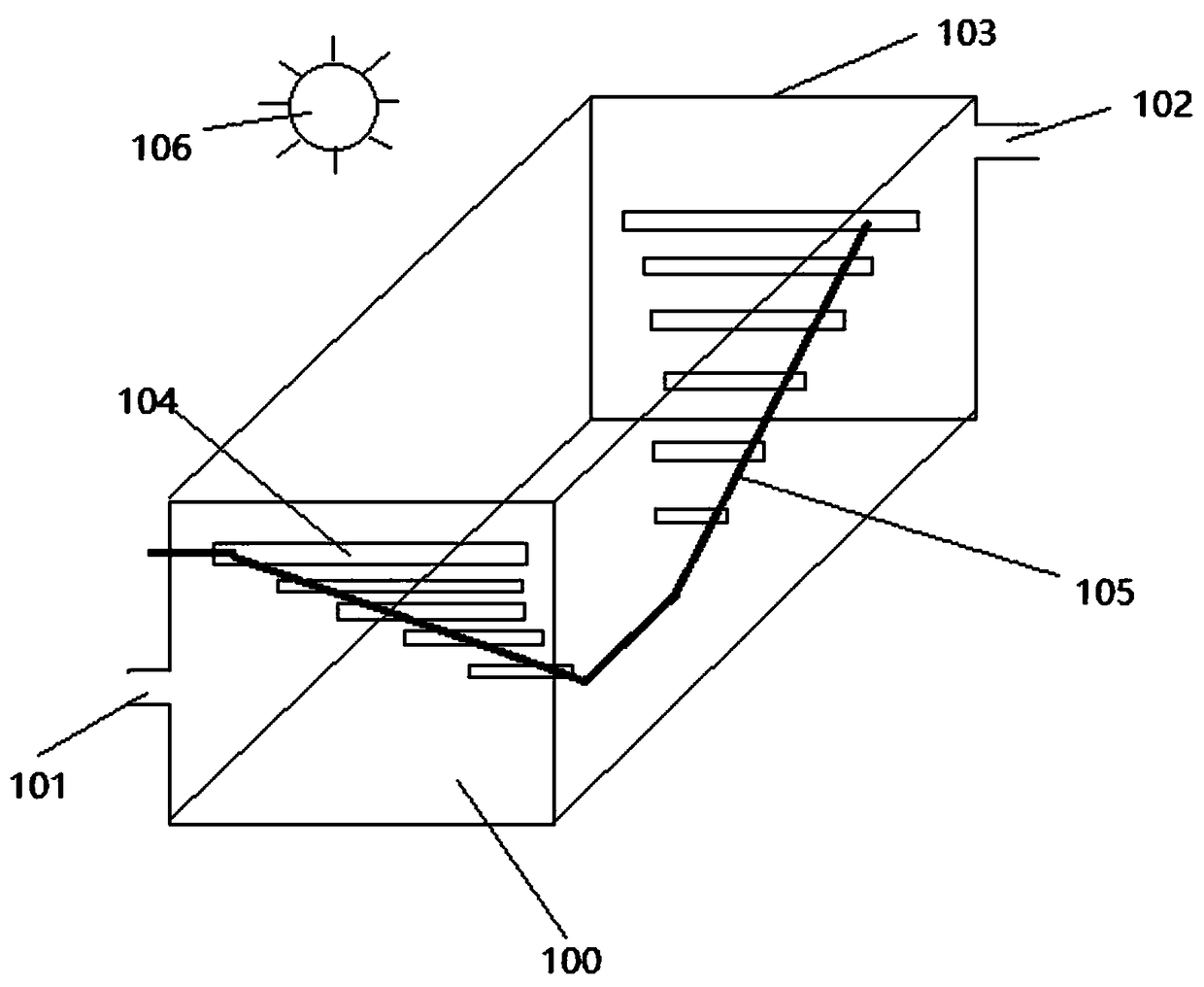

[0037] The system for the pretreatment of pharmaceutical wastewater according to the present invention includes: a reservoir 100, which includes a water inlet 101 and a water outlet 102, and the level of the water inlet 101 is lower than the level of the water outlet 102, so as to Facilitate the settling of particulate matter. A transparent upper cover 103 is provided on the top of the reservoir 100. The transparent upper cover 103 may be made of quartz or plexiglass to have better light transmission, improve the transmittance of visible light and ultraviolet light, and improve the oxidation efficiency. A light source 106 is arranged above the transparent upper cover 103, and the light source 106 is selected from one or both of fluorescent lamps and ultraviolet light lamps. Therefore, the method of aeration can be appropriately selected according to the type and concentration of pharmaceutic...

Embodiment 2

[0039] Embodiment 2 catalyst and preparation method thereof

[0040] The oxidation tube of the pharmaceutical wastewater treatment system according to the present invention is filled with a catalyst, and the catalyst is preferably a supported catalyst. Among them, the supported catalyst is prepared by using a material with a large specific surface area as a carrier, and the nano-heteropolyacid salt is loaded on the carrier by an impregnation method, and the carrier is selected from activated carbon, attapulgite, silicon dioxide or zeolite.

[0041] Wherein, the nano-heteropolyacid salt catalyst is prepared by a method comprising the following steps:

[0042] Weigh a certain amount of molybdate and put it in an appropriate amount of distilled water, dissolve it and add it to a certain amount of metavanadate boiling water solution, cool it down, add concentrated sulfuric acid to adjust its pH value below 4, heat the mixture under reflux for 8 hours and slowly Add concentrated s...

Embodiment 3

[0047] (1) Loading a load-type catalyst (10% loading capacity, 2% wastewater treatment quality) with a quality of 1kg into the oxidation tube;

[0048] (2) Pass 50kg of chemical and pharmaceutical wastewater (COD 12000) into the oxidation tube, turn on the ultraviolet light source, control the ozone pressure at 0.09MPa, and mix it thoroughly with ultrasonic waves before entering the oxidation tube. The particle size of the ozone bubbles is controlled at 100nm-2μm between;

[0049] (3) Turn on the gas recovery and circulation device, collect the unreacted ozone and enter the bubble generating device to realize recycling;

[0050] (4) After the wastewater reacts in the catalytic oxidation tube for 80 minutes, the COD of the water is detected to be 1530 mg / L, and it enters the subsequent treatment process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com