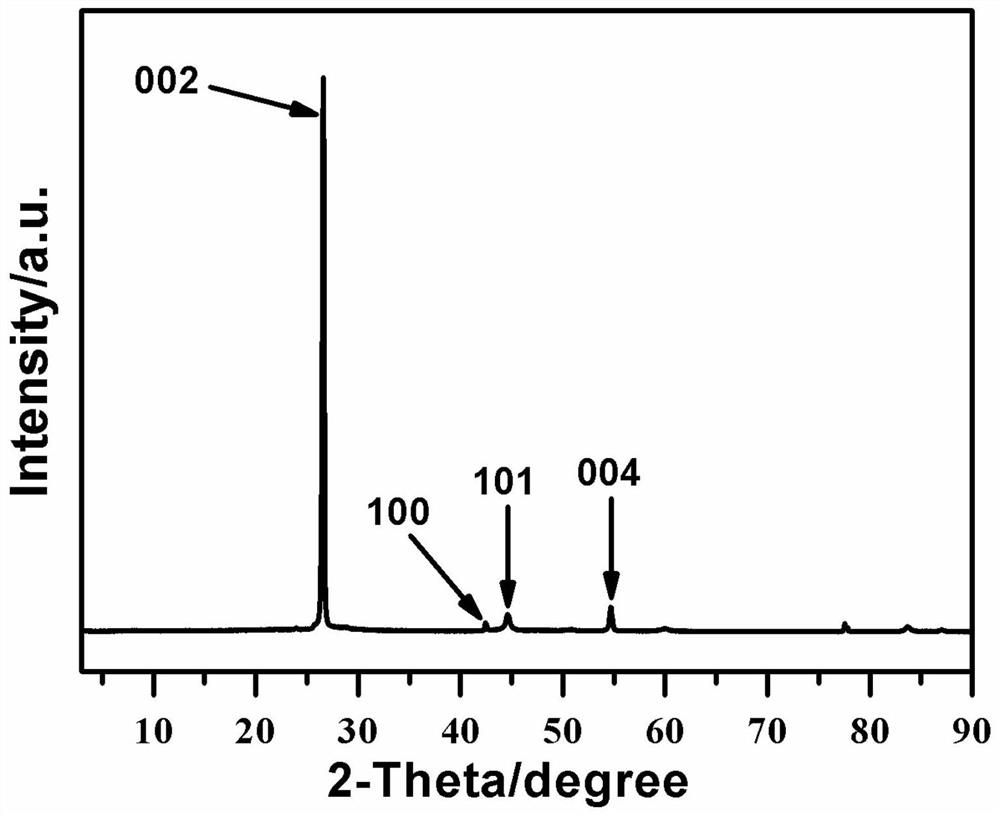

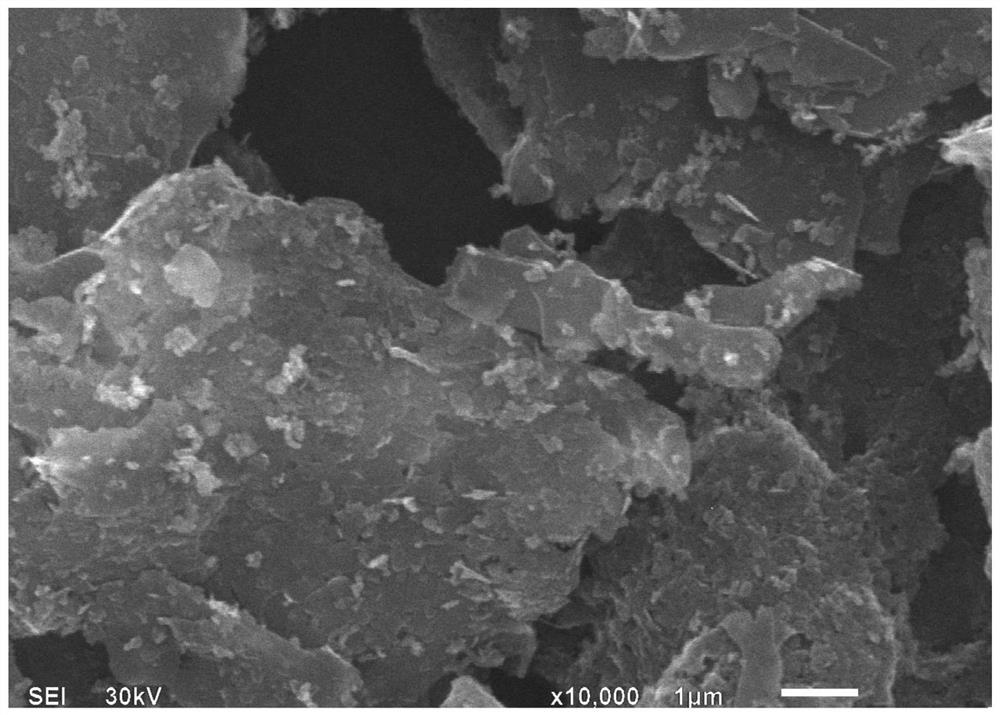

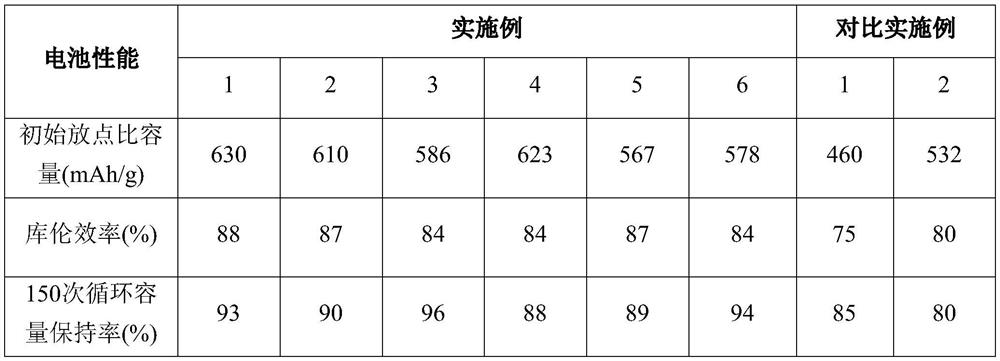

A kind of carbon/silicon/carbon composite material and its preparation method and application

A carbon composite material and carbon material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of difficulty in meeting the high requirements of lithium-ion batteries, low cycle capacity retention rate, equipment requirements and high energy consumption, and achieve The effect of shortening the preparation cycle, improving the interface compatibility, and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1: Add 15g of artificial graphite to 450mL of 30% hydrogen peroxide, react at 50°C for 3h under stirring conditions of 800r / min to oxidize the artificial graphite, filter the reacted mixture and wash the filter cake with deionized water, when washing After the liquid pH=7, the filter cake was dried to a constant weight to obtain 14.52 g of oxidized artificial graphite.

[0051] Step 2: Add 10g of oxidized artificial graphite to the flat bottom flask, then add 10mL of deionized water and 30mL of absolute ethanol, adjust the resulting mixture to pH = 2 with 0.1mol / L hydrochloric acid, then add 2g of vinyl triethoxy Silane and 7.5g tetraethyl orthosilicate, the mixture was ultrasonically treated for 20min, then transferred to a microwave reactor with a power of 300W, microwaved at 50°C for 2min, filtered, the filter cake was washed with absolute ethanol, and vacuum-dried at 150°C After 2h, 11.12g of precursor 1 was obtained.

[0052] Step 3: Mix 5g of precursor 1 and...

Embodiment 2

[0056] Step 1: Add 15g of natural graphite to 400mL of 65% nitric acid, react at 25°C and 800r / min for 4h to oxidize the natural graphite, filter the reacted mixture and wash the filter cake with deionized water, when the pH of the washing solution After =7, the filter cake was dried to constant weight to obtain 14.34g of oxidized natural graphite.

[0057] Step 2: Add 10g of oxidized natural graphite to a flat-bottomed flask, then add 10mL of deionized water and 40mL of isopropanol, adjust the resulting mixture to pH = 2 with 0.1mol / L nitric acid, then add 2.5g of aminopropyl triethoxy Silane and 6.8g tetraethyl orthosilicate, the mixture was ultrasonically treated for 15min, then transferred to a microwave reactor with a power of 200W, microwaved at 30°C for 1min, filtered, the filter cake was washed with absolute ethanol, and vacuum-dried at 150°C After 2h, 10.62g of precursor 1 was obtained.

[0058] Step 3: Mix 5g of precursor 1 and 2g of nano-magnesium powder and place ...

Embodiment 3

[0062] Step 1: Add 17g of mesocarbon microspheres to 400mL of 98% concentrated sulfuric acid, react at 40°C for 3h under 600r / min stirring conditions to oxidize the mesocarbon microspheres, filter the reacted mixture and use deionized The filter cake was washed with water, and when the pH of the washing solution was 7, the filter cake was dried to a constant weight to obtain 15.89 g of oxidized mesocarbon microspheres.

[0063] Step 2: Add 10 g of oxidized mesophase carbon microspheres to a flat-bottomed flask, then add 10 mL of deionized water and 25 mL of ethyl acetate, adjust the resulting mixture to pH = 2 with 1 mol / L sulfuric acid, and then add 8 g of ethyl orthosilicate , after the mixture was sonicated for 20 min, it was transferred to a microwave reactor with a power of 400 W, microwaved at 35 °C for 5 min, filtered, the filter cake was washed with absolute ethanol, and 10.82 g of precursor 1 was obtained after vacuum drying at 150 °C for 2 h.

[0064] Step 3: Mix 5g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com