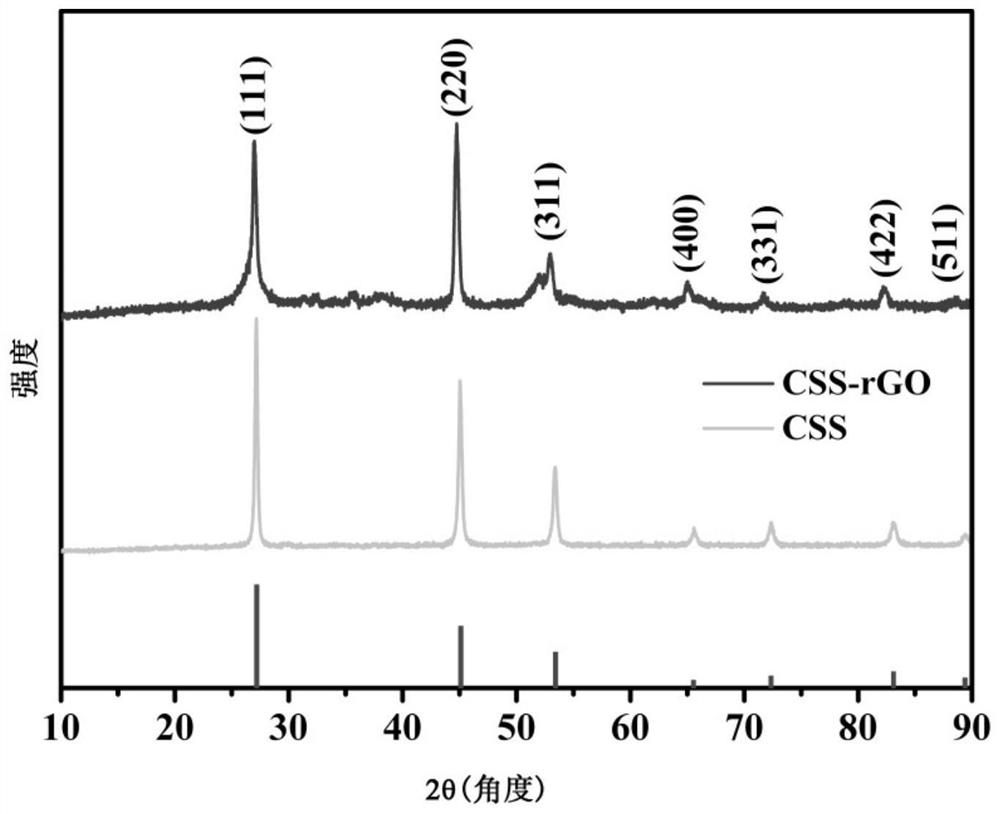

Selenide-containing composite material and preparation method and application thereof

A composite material and a selenide technology, which are applied in the field of selenide-containing composite materials and the preparation thereof, can solve the problems of difficult control of the structure of the selenide material, difficulty in the preparation of the high-performance multi-element metal selenide composite structure, etc. Controllable, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

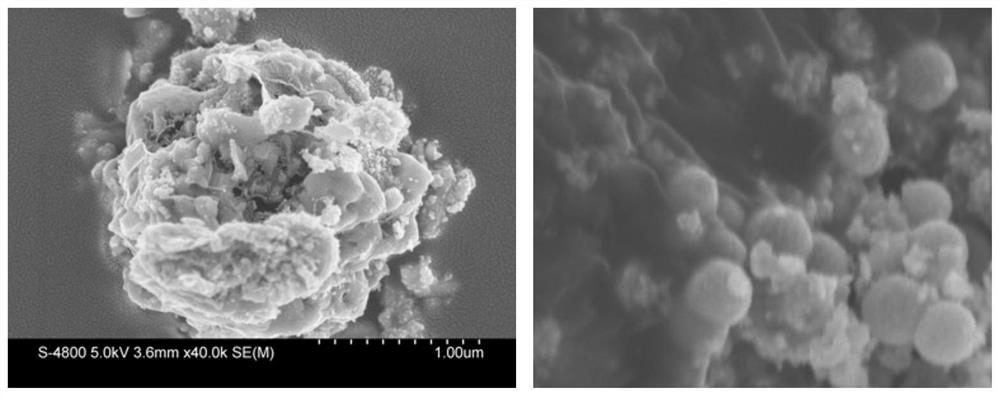

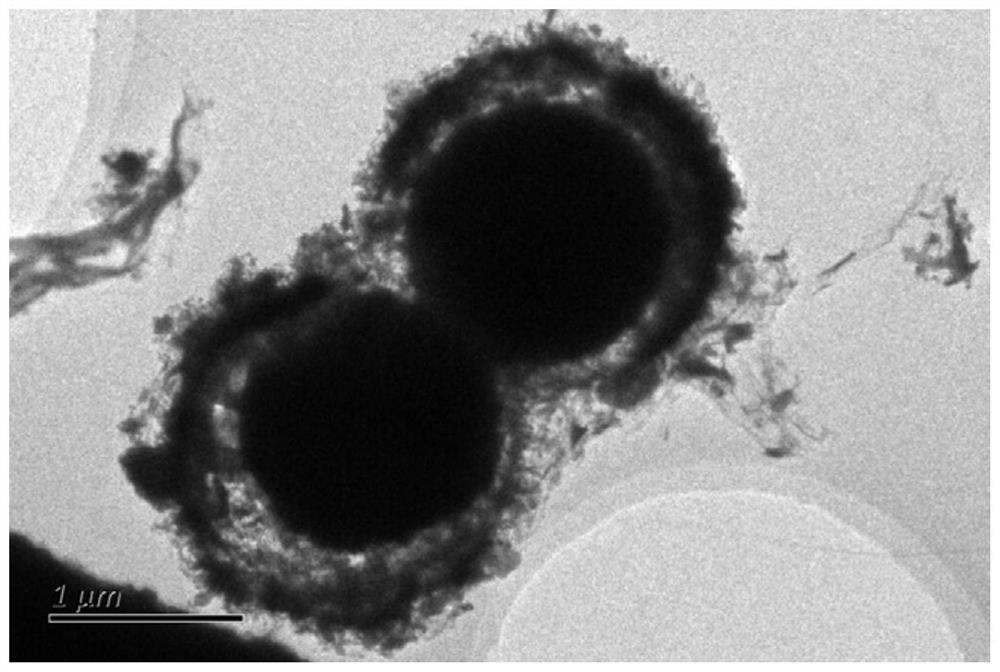

Embodiment 1

[0044] This embodiment provides a method for preparing a composite material containing selenide, which specifically includes the following steps,

[0045] (1) Take 3.2mmol NaSnO 3 Add to 60mL deionized water to form NaSnO 3 Aqueous solution; ultrasonically disperse 50mg of graphene oxide powder into 95mL of deionized water for 30min to form an aqueous solution of graphene oxide; dissolve 3.2mmol of CuSO 4 ·5H 2 O was added to the graphene oxide aqueous solution, placed in a cold bath, stirred and cooled to 0°C, 800mL of ammonia water was added to it, the pH was adjusted to 9, and the solution was stirred rapidly until the color of the solution turned dark blue, and then NaSnO was added drop by drop. 3 Aqueous solution, dropwise time is 30min, obtain CuSn(OH) 6 Precipitation; CuSn(OH) 6 After the precipitate was centrifuged at high speed, washed with water and alcohol until the filtrate was neutral, it was dried in an oven for 24 hours to obtain CuSn(OH) 6 powder; then the...

Embodiment 2

[0057] This embodiment provides a method for preparing a composite material containing selenide, which specifically includes the following steps,

[0058] (1) Take 2.8mmol NaSnO 3 Add to 60mL deionized water to form NaSnO 3 aqueous solution; ultrasonically disperse 55 mg of graphene oxide powder into 95 mL of deionized water for 30 min to form an aqueous solution of graphene oxide; 3.2 mmol of Fe(NO 3 ) 2 Add graphene oxide aqueous solution, put it in a cold bath, stir and cool to 0°C, add 700mL ammonia water to it, adjust the pH to 8, stir quickly, and then add NaSnO drop by drop 3 Aqueous solution, dropwise time is 30min, obtain FeSn(OH) 6 Precipitation; FeSn(OH) 6 After the precipitate is centrifuged at high speed, washed with water and alcohol until the filtrate is neutral, it is dried in an oven for 24 hours to obtain FeSn(OH) 6 powder; then the powder was calcined in a tube furnace at 350°C for 2h to obtain FeSnO 3 powder. Wherein, the centrifugation time is 10 mi...

Embodiment 3

[0062] This embodiment provides a method for preparing a composite material containing selenide, which specifically includes the following steps,

[0063] (1) Take 3.4mmolNaSnO 3 Add to 60mL deionized water to form NaSnO 3 aqueous solution; ultrasonically disperse 60 mg of graphene oxide powder into 95 mL of deionized water for 30 min to form an aqueous solution of graphene oxide; dissolve 3.2 mmol of NiSO 4 ·6H 2 O was added to the graphene oxide aqueous solution, placed in a cold bath and stirred to cool to 0°C, and 1000mL of ammonia water was added to it, and the pH was adjusted to 10, stirred rapidly, and then NaSnO was added drop by drop. 3 Aqueous solution, dropwise time is 30min, get NiSn(OH) 6 Precipitation; NiSn(OH) 6 After the precipitate is centrifuged at high speed, washed with water and alcohol until the filtrate is neutral, it is dried in an oven for 24 hours to obtain NiSn(OH) 6 powder; then the powder was calcined in a tube furnace at 350°C for 2h to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com