Palladium/titanium dioxide/graphene catalyst and preparation method thereof

A technology of titanium dioxide and graphene, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to improve corrosion resistance, simple method and process, and good oxygen reduction catalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

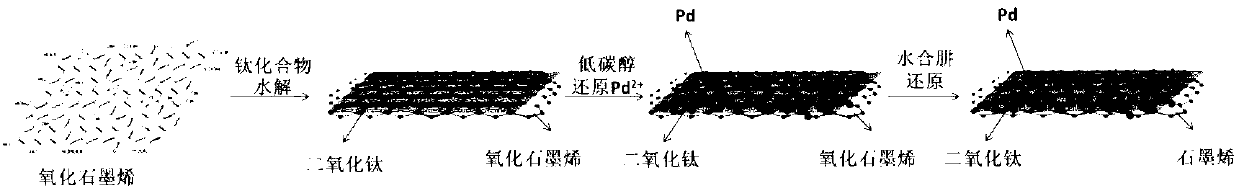

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of graphite oxide: take 2 grams of graphite to prepare graphite concentration of 40 grams per liter of H 2 SO 4 Suspension 0.05 L, then weigh 0.2 g KMnO 4 Slowly add to the above H under ice bath 2 SO 4 suspension, 30 o Stir and react for 3 hours at C; add deionized water to the above suspension, dilute the graphite concentration to 0.6 g / L, and raise the temperature to 90 o C reacted for 20 minutes; weighed 0.4 g of 0.5% H 2 o 2 The solution was added to the above reaction solution to terminate the reaction; washed with 1 mol / L HCl solution, centrifuged at 3000 rpm to remove the supernatant, and repeated several times until no SO4 was detected in the supernatant 4 2- ; the collected samples at 60 o C vacuum dried for 10 hours to obtain graphite oxide.

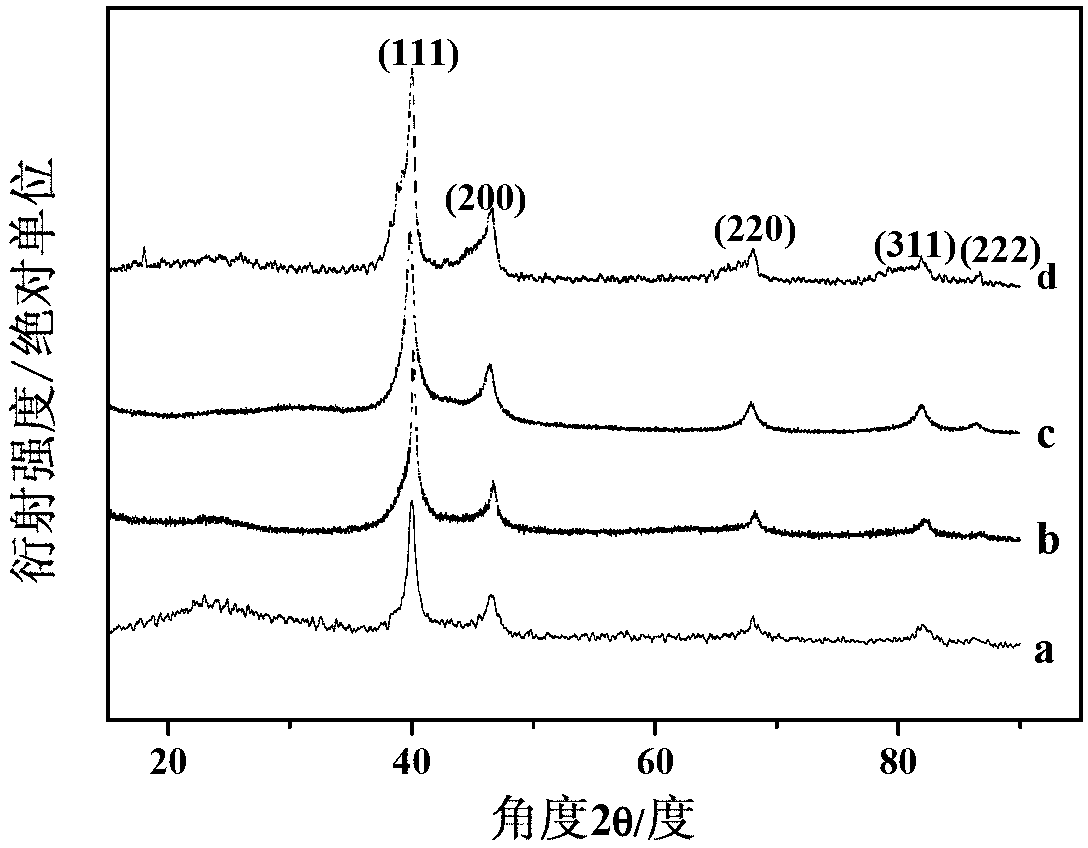

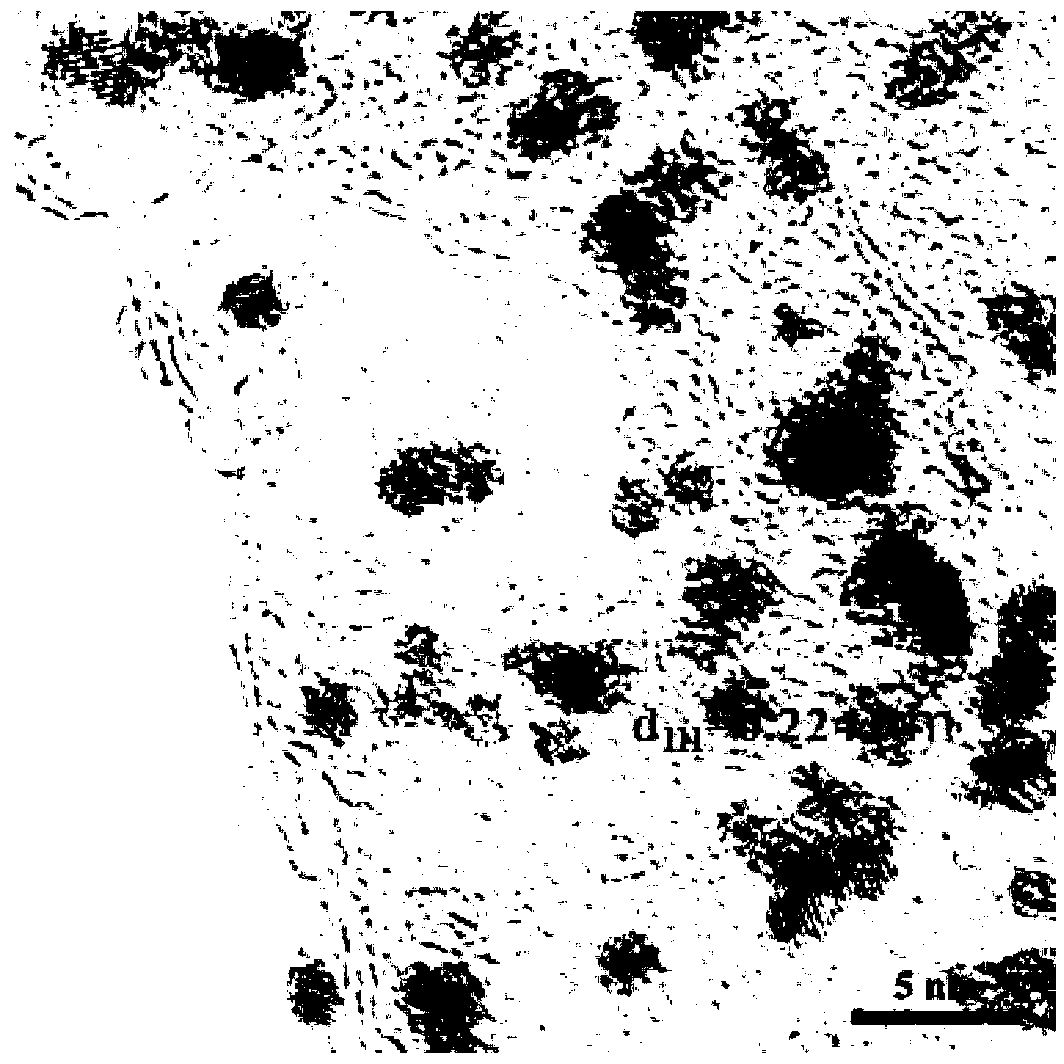

[0033] (2) Pd / TiO 2 Preparation of (5%) / G: Weigh 0.1 gram of graphite oxide and disperse it in methanol solvent to prepare 0.2 liters of a suspension with a graphite oxide concentration of 0.5 ...

Embodiment 2

[0037] (1) Preparation of graphite oxide: Weigh 2.174 grams of graphite to prepare graphite H with a graphite concentration of 43.48 grams per liter. 2 SO 4 Suspension 0.05 L, then weighed 0.145 g KMnO 4 Slowly add to the above H under ice bath 2 SO 4 suspension, 35 o Stir the reaction at C for 2 hours; add deionized water to the above suspension, dilute the graphite concentration to 0.9 g / L, and raise the temperature to 95 o C reacted for 15 minutes; Weighed 0.403 grams of H with a mass fraction of 0.6% 2 o 2 The solution was added to the above reaction solution to terminate the reaction; washed with 1.25 mol / L HCl solution, centrifuged at 4000 rpm to remove the supernatant, and repeated several times until no SO4 was detected in the supernatant 4 2- ; the collected samples at 50 o C vacuum dried for 12 hours to obtain graphite oxide.

[0038] (2) Pd / TiO 2 Preparation of / G: Weigh 0.1 gram of graphite oxide and disperse it in ethylene glycol solvent to prepare 0.12...

Embodiment 3

[0042] (1) Preparation of graphite oxide: take 2 grams of graphite to prepare graphite H with a graphite concentration of 50 g / L 2 SO 4 Suspension 0.04 L, then weigh 0.1 g KMnO 4 Slowly add to the above H under ice bath 2 SO 4 suspension, 40 o Stir the reaction at C for 1 hour; add deionized water to the above suspension, dilute the graphite concentration to 1.2 g / L, and raise the temperature to 100 o C reacted for 10 minutes; Weighed 0.333 grams of H with a mass fraction of 0.75% 2 o 2 The solution was added to the above reaction solution to terminate the reaction; washed with 1.5 mol / L HCl solution, centrifuged at 5000 rpm to remove the supernatant, and repeated several times until no SO4 was detected in the supernatant 4 2- ; Collected samples at 40 o C vacuum dried for 14 hours to obtain graphite oxide.

[0043] (2) Pd / TiO 2 Preparation of / G: Weigh 0.1 gram of graphite oxide and disperse it in a glycerol solvent to prepare 0.1 liter of a suspension with a graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com