Patents

Literature

37results about How to "Excellent oxygen reduction catalytic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

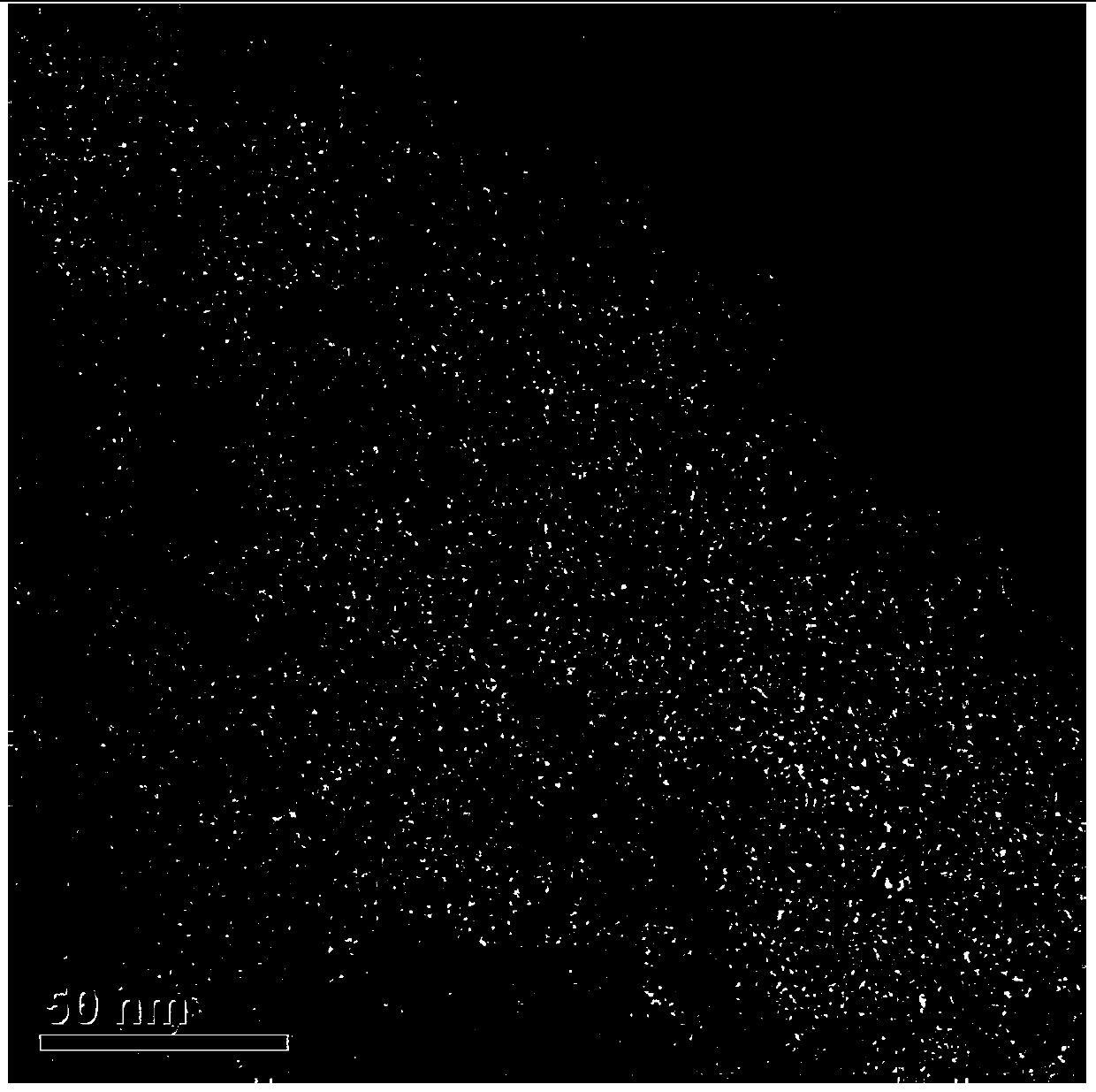

Non-noble metal catalyst used for catalytic oxygen reduction and preparation method thereof

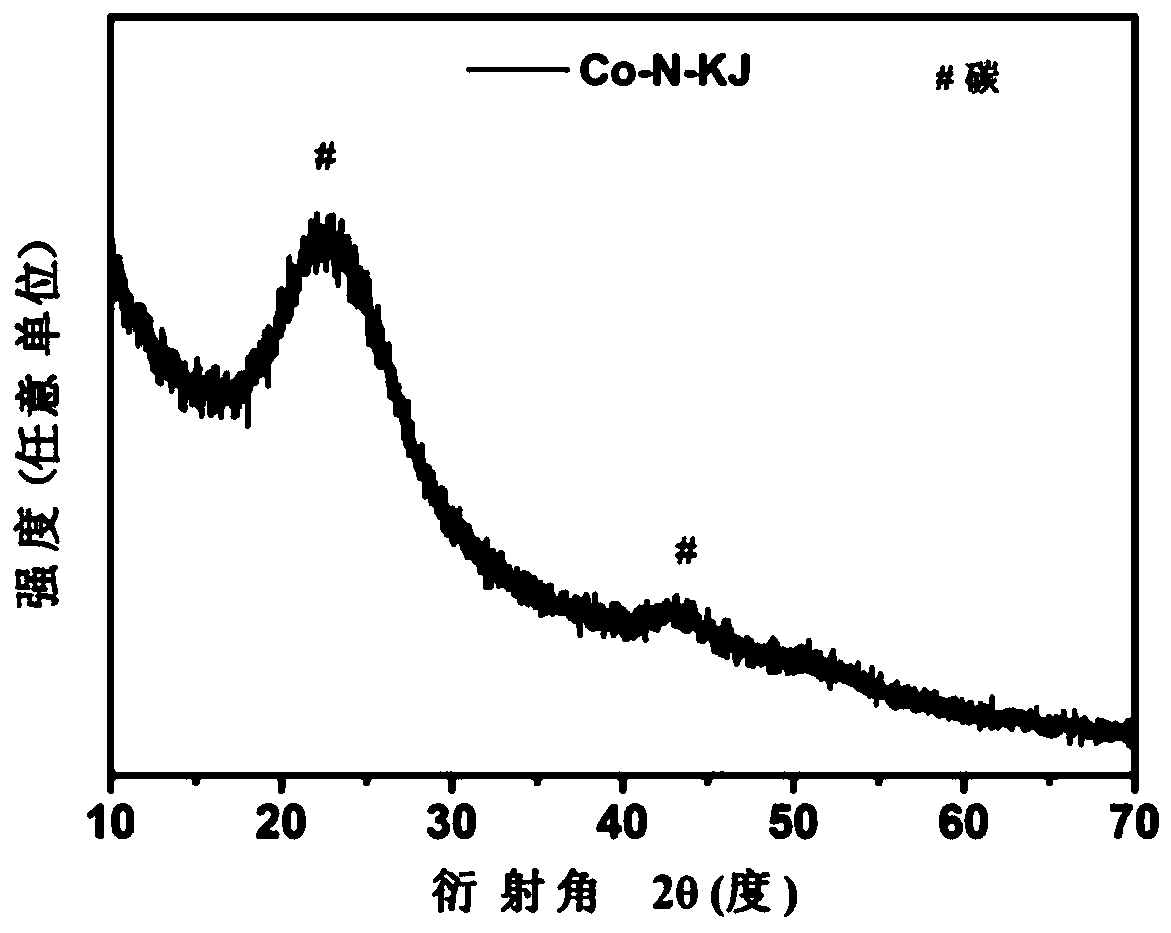

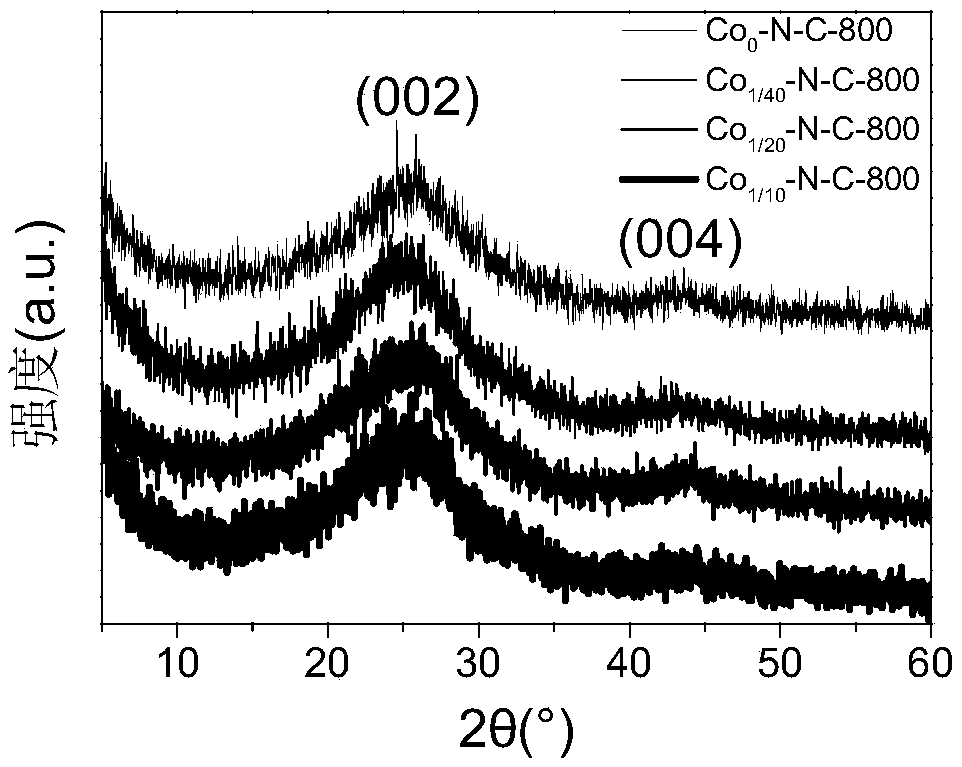

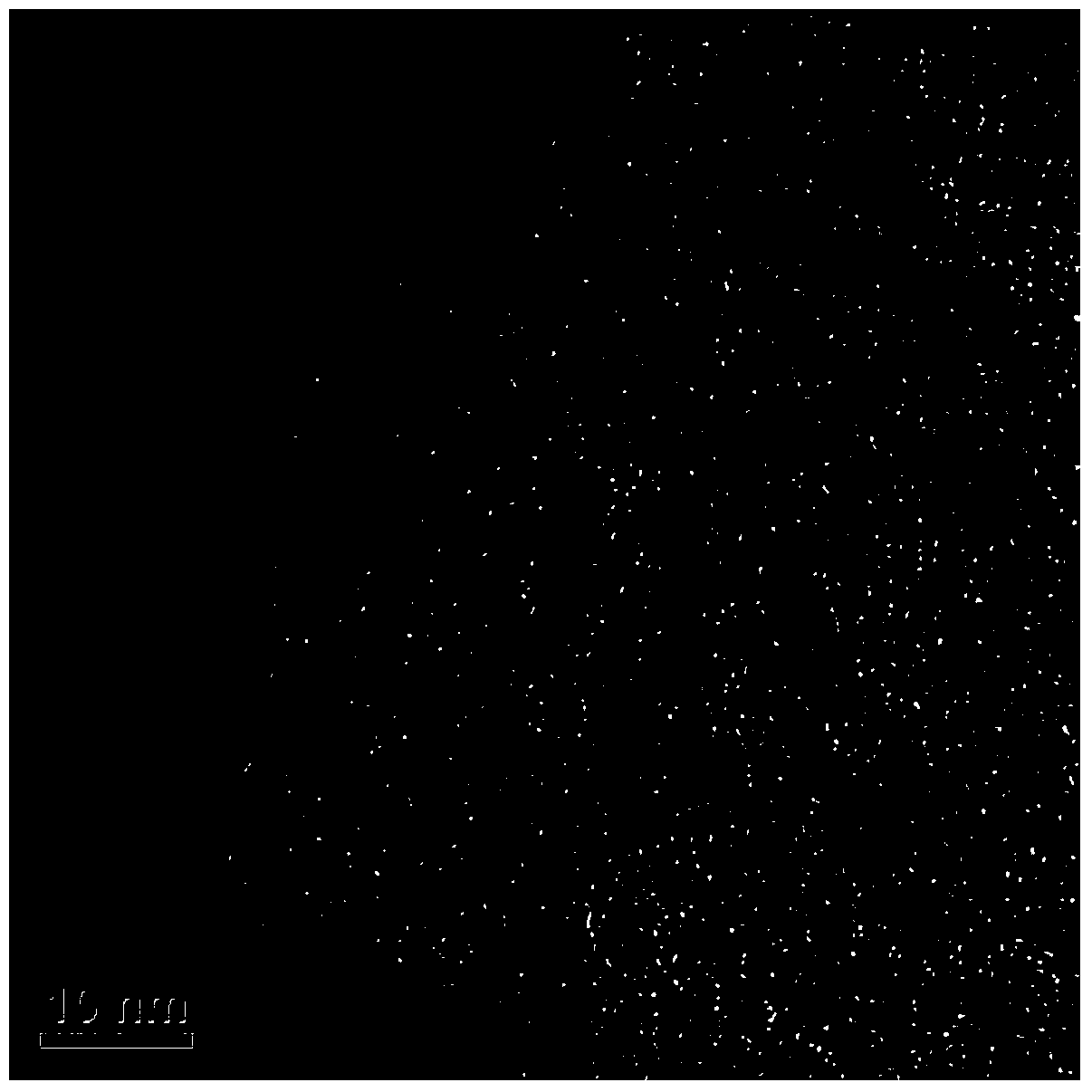

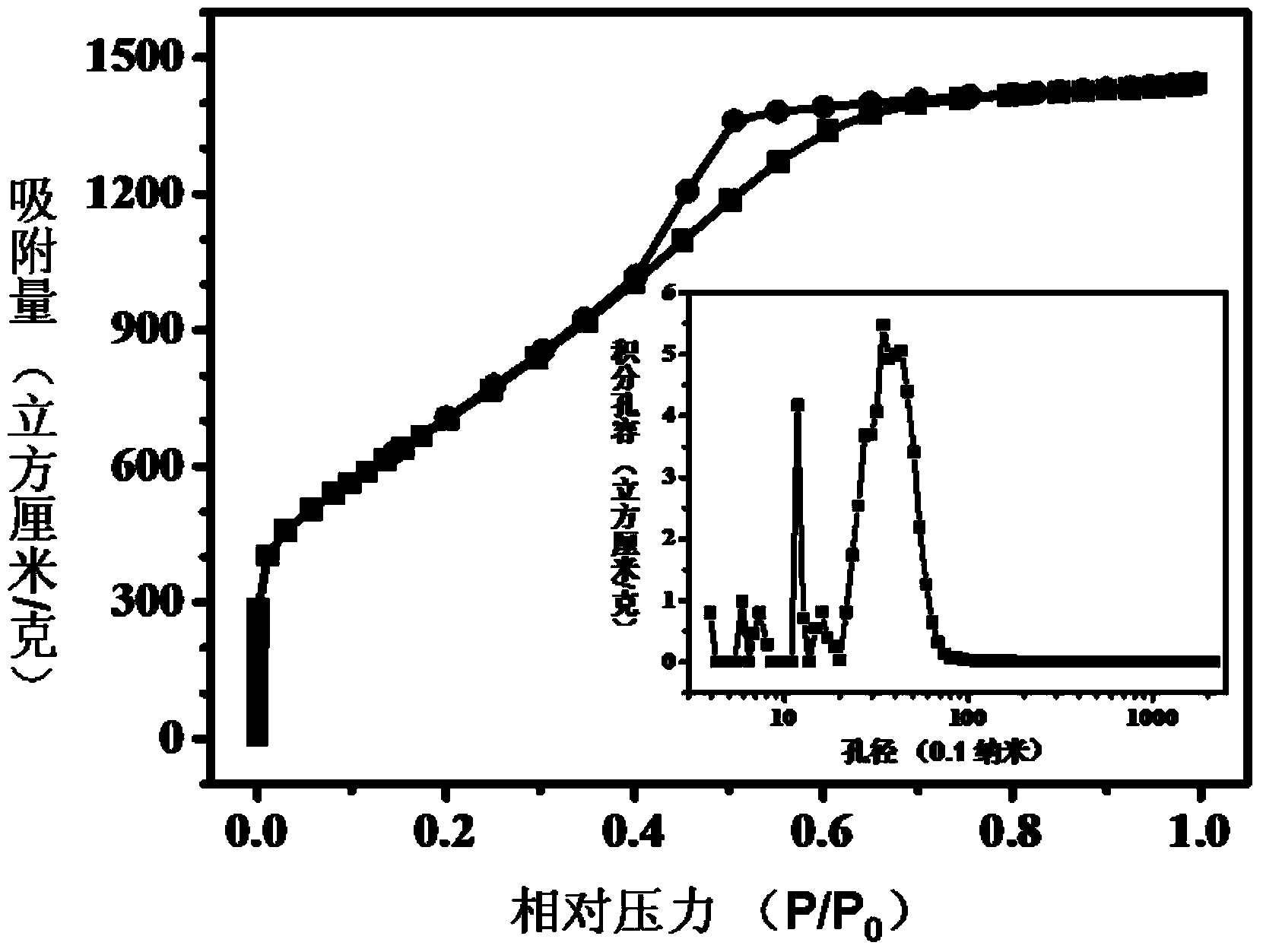

ActiveCN108963276AImprove conductivityCapable of single-atom dispersionFuel and secondary cellsCell electrodesOxygenCalcination

The invention relates to a non-noble metal catalyst used for catalytic oxygen reduction and a preparation method thereof. The catalyst has the general formula of Me-N-C. By means of adsorption capability and range-limited calcination of the active carbon, non-noble metal atoms, Me and N which are dispersed to the atomic scale, are adsorbed and limited in the pores in the active carbon C, so that on the basis of high-electro-conductivity of the active carbon, a high-effective oxygen reduction catalyst having single-atom-dispersing capability can be obtained. The non-noble metal catalyst is lowin metal content, can be prepared at low cost and has very large specific surface area, wherein the Me and N are distributed in interior of pores in the active carbon, in a mono-atom dipsersed manner,instead of on the surface of the active carbon, so that excellent mass transfer capability and conductivity are achieved. The catalyst has excellent oxygen reduction catalytic activity, can be applied to preparation of MEA membrane electrodes and cathode catalytic reaction process of large-scale Zn-air batteries, Al-air batteries and fuel cell stacks. The invention provides the high-effective andstable catalyst for the MEA membrane electrode.

Owner:UNIV OF SCI & TECH OF CHINA

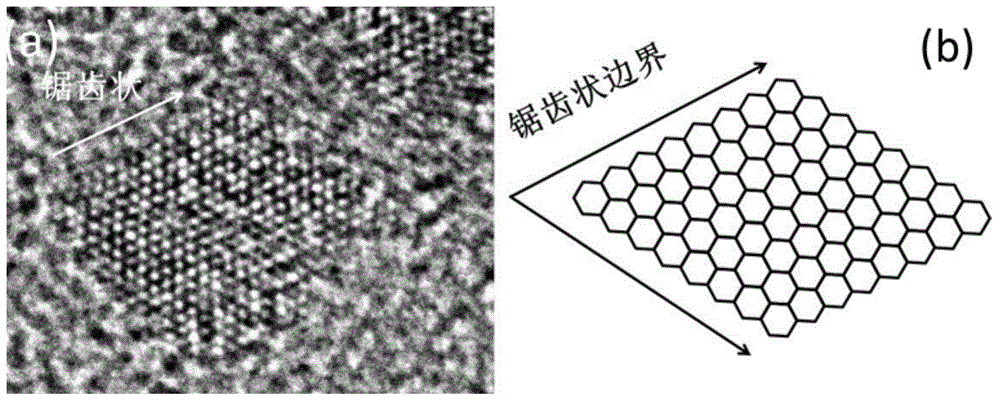

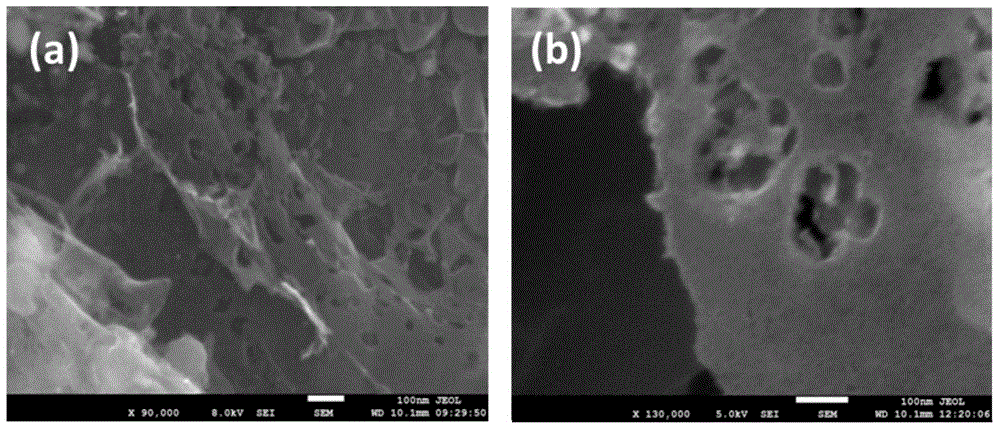

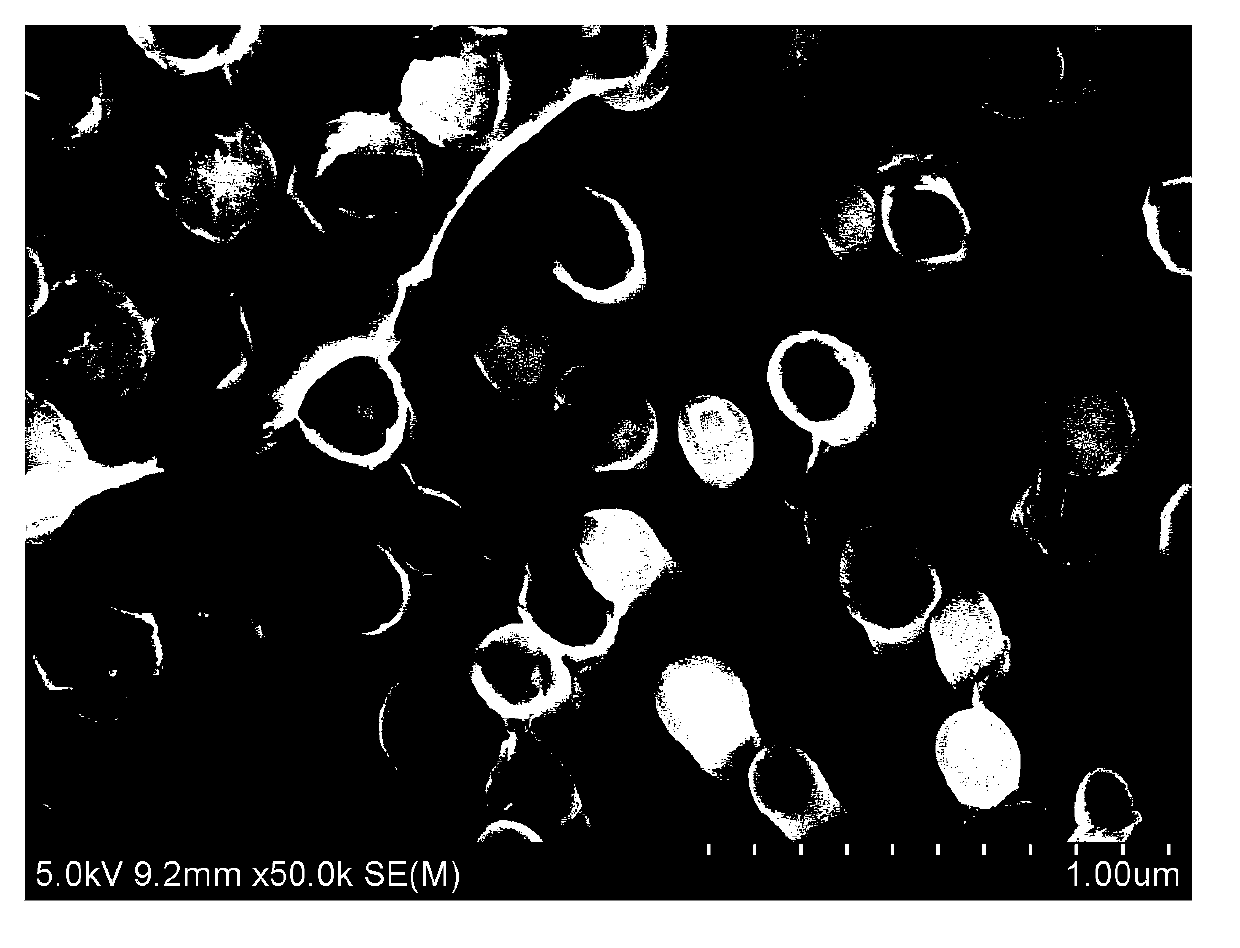

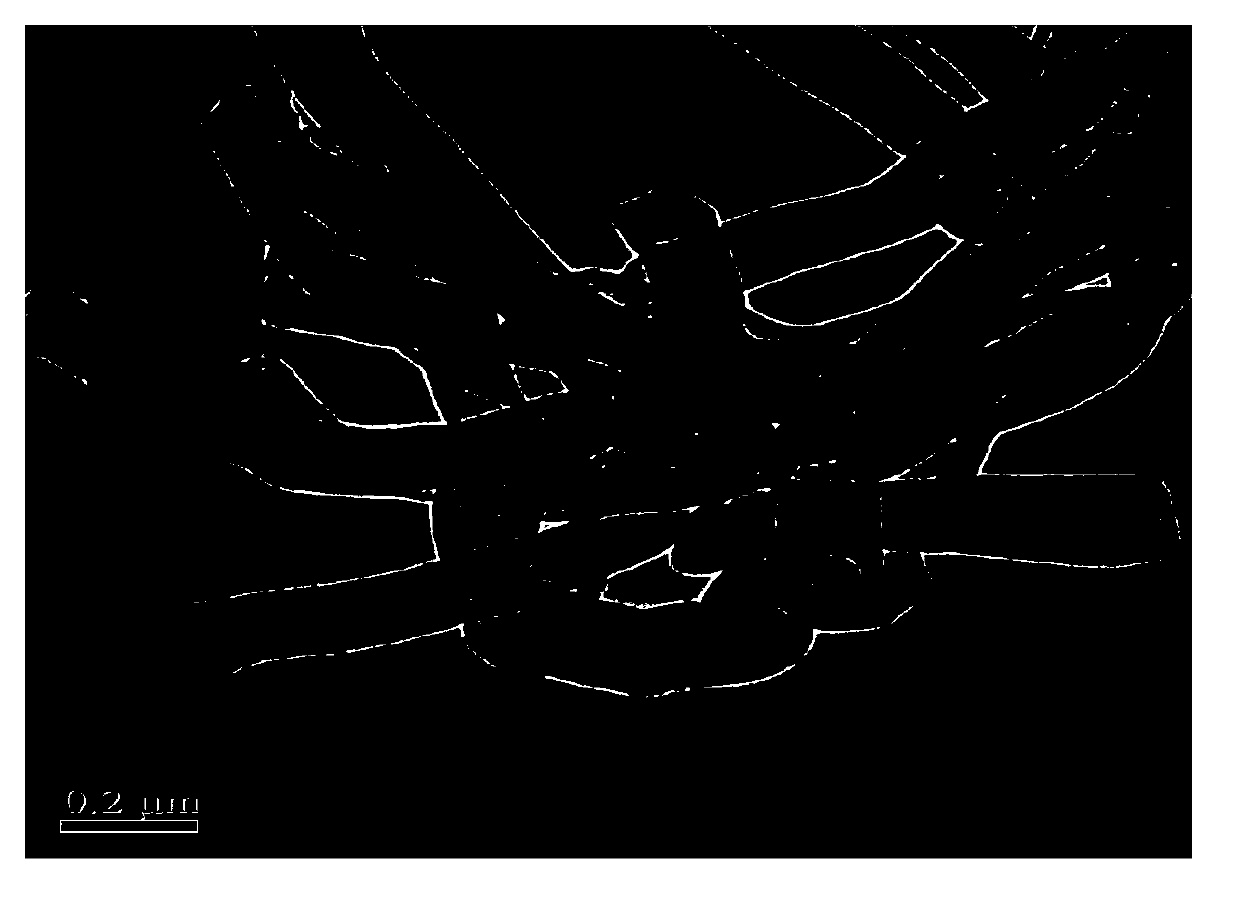

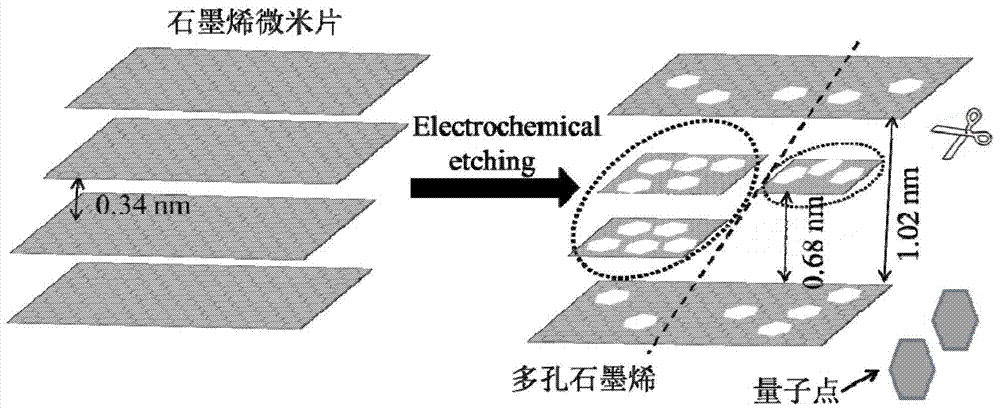

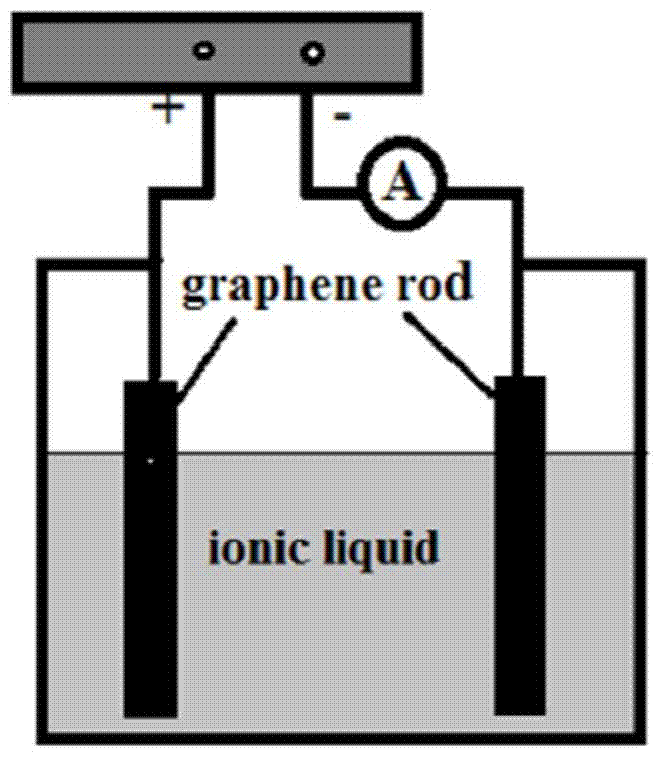

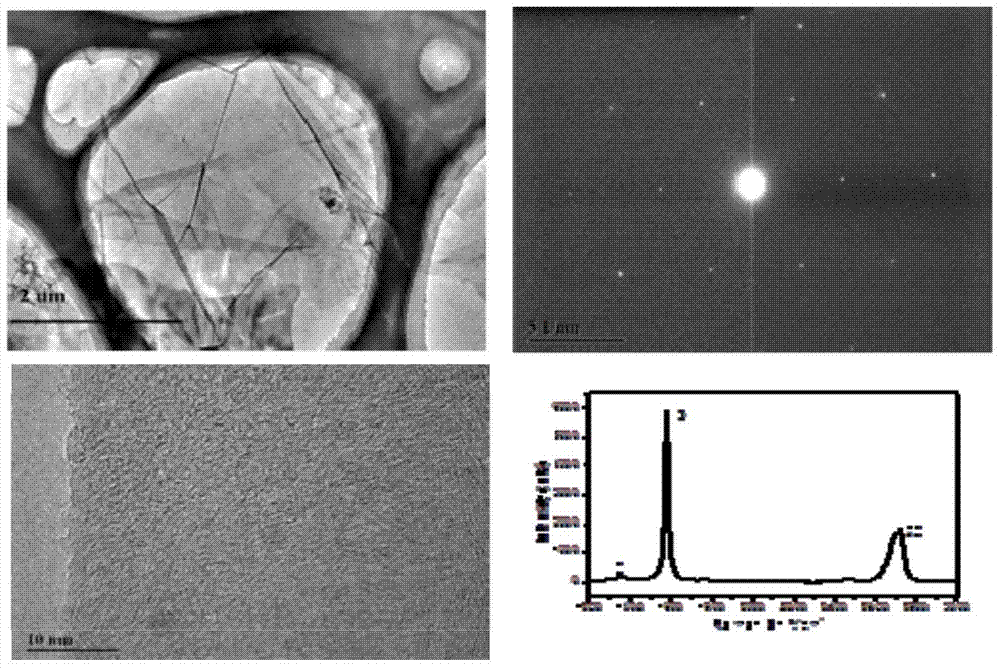

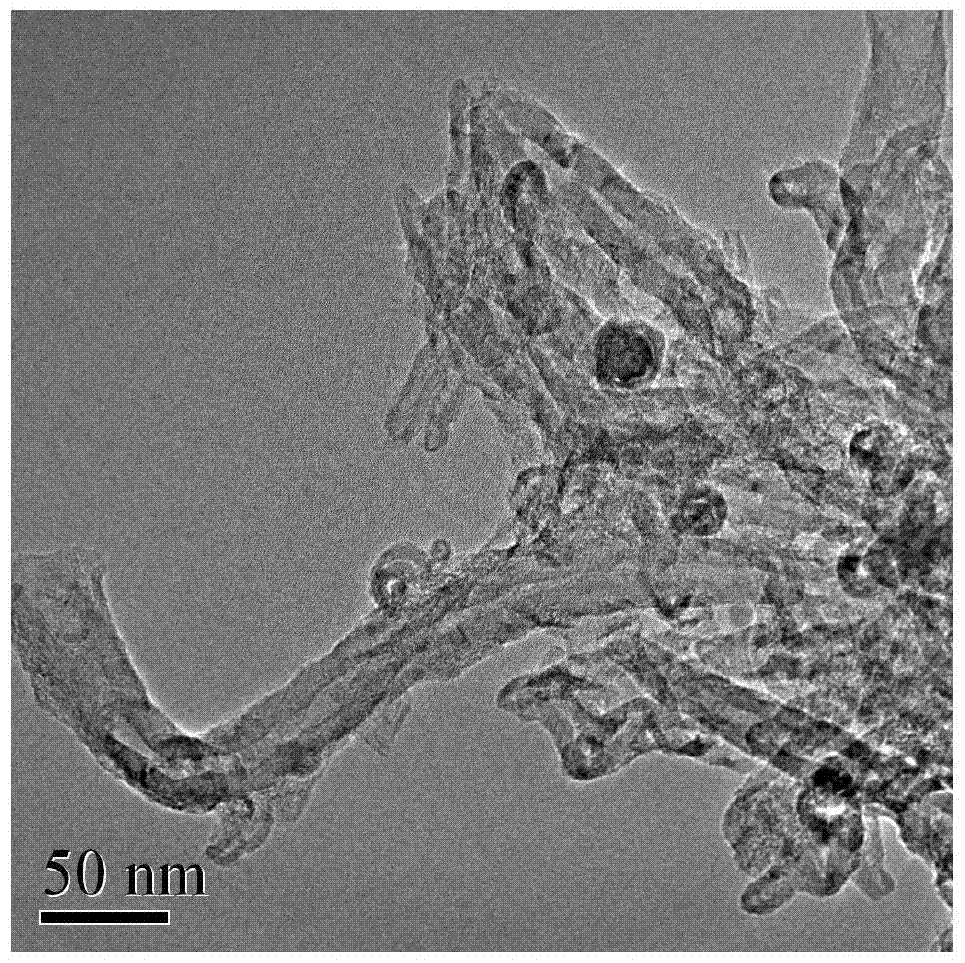

Porous graphene and graphene quantum dot and preparation method of porous graphene and graphene quantum dot

ActiveCN104555999AUniform pore size distributionExcellent oxygen reduction catalytic activityPorous grapheneCvd graphene

The invention discloses porous graphene and a graphene quantum dot. The porous graphene comprises, but is not limited to 2-9 atomic layers, wherein each atomic layer simultaneously comprises crystal lattices and holes of graphene, but is not limited to the holes of which the apertures are 2-10nm; the area of the holes accounts for about 5%-40% of total area of each atomic layer. The graphene quantum dot is characterized by comprising 1-5 atomic layers; the boundary is in a sawtooth shape; and the dimension of the quantum dot is 2-10nm. The porous graphene disclosed by the invention is uniform in aperture distribution, and not equal in interlayer spacing; and the graphene quantum dot has the advantages of high luminous efficacy, good crystal form and few defects.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Oxygen reduction non-noble metal catalyst and preparation method thereof

InactiveCN102626649AImprove conductivityHigh degree of graphitizationPhysical/chemical process catalystsCell electrodesInorganic compoundOxygen

The invention which provides an oxygen reduction non-noble metal catalyst and a preparation method thereof belongs to the technical field of fuel cells. The nitrogen doped non-noble metal fuel cell catalyst having a graphite-like structure is formed by introducing nitrogen-containing monomers into layered inorganic compound interlayers and carrying out interlayer polymerization-pyrolysis. The active nitrogen loss is effectively reduced and the graphitization degree of the catalyst is effectively improved by utilizing an almost closed effect of the layered compound to improve the catalytic activity and the stability of the non-noble metal catalyst. The method of the invention has the advantages of simplicity and easy implement, and low production cost; and the catalyst prepared through the method has the advantages of good oxygen reduction catalytic activity and good stability, and can be applied to a fuel cell with a proton exchange membrane as an electrolyte. The fuel cell manufactured with the catalyst can be widely applied to electric automobiles, various spacecrafts, and portable electronic devices, such as cameras, notebook computers, electric toys and the like.

Owner:CHONGQING UNIV

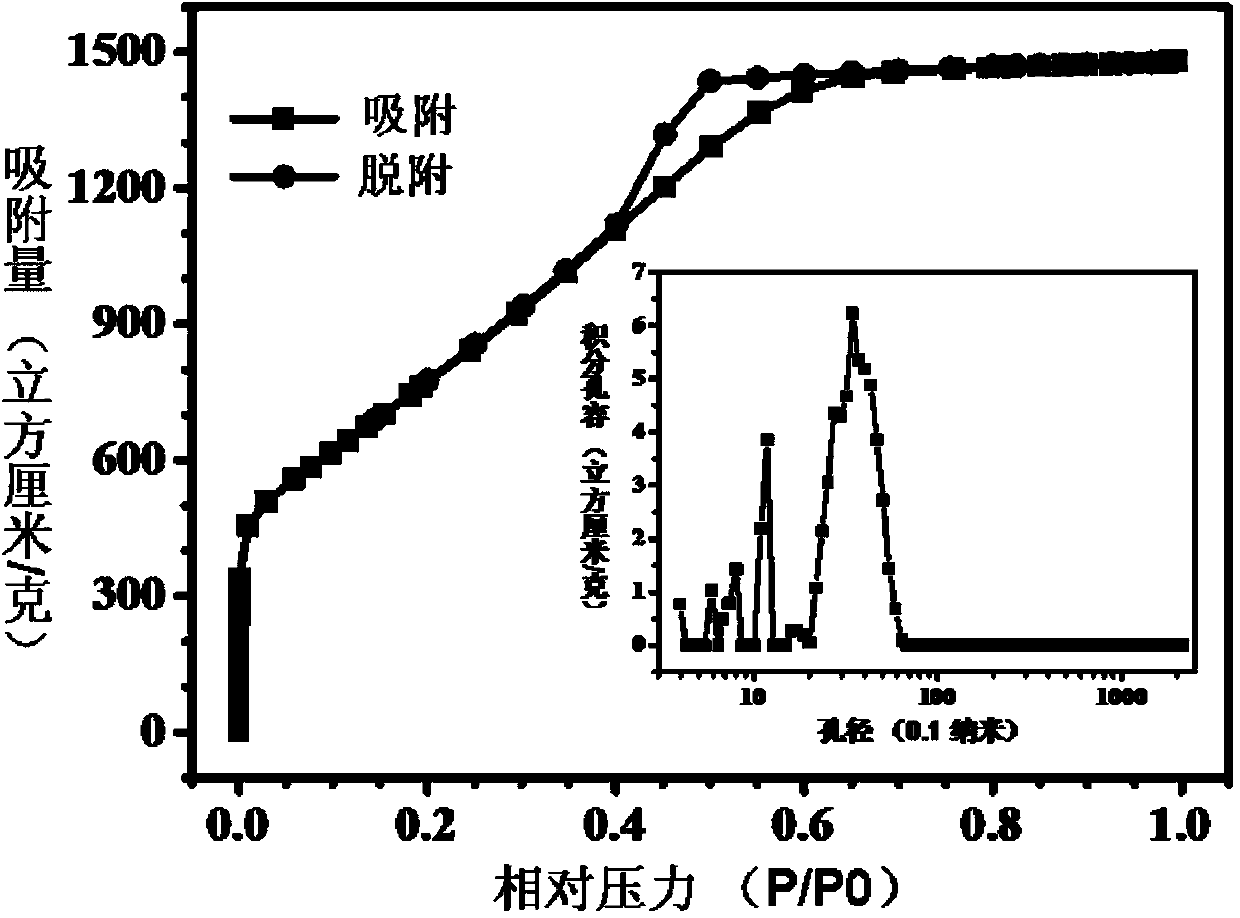

Preparation method for nitrogen-doped carbon oxygen reduction catalyst with hierarchical porous structure

ActiveCN105186010AExcellent oxygen reduction catalytic activitySimple methodCell electrodesFreeze-dryingOxygen

The invention provides a preparation method for a nitrogen-doped carbon oxygen reduction catalyst with a hierarchical porous structure, belonging to the technical field of a fuel cell. The preparation method comprises the following steps of: firstly, preparing a eutectic molten salt having a three-dimensional macro-porous structure by a freeze drying method; secondly, using the eutectic molten salt as a template, doping a nitrogen-containing precursor, and leading the nitrogen-containing precursor to be oxidized and polymerized on the surface of the eutectic molten salt by a solid-phase polymerization method, wherein ammonium persulfate serves as an oxidizing agent, and a ferric salt serves as a promoter; and finally, carrying out high-temperature pyrolysis and removing the eutectic molten salt. With the adoption of the nitrogen-doped carbon oxygen reduction catalyst with the hierarchical porous structure, the nitrogen-containing precursor can be effectively prevented from pyrolysis loss, structural collapse and sintering during the high-temperature carbonation process, the catalyst yield and the nitrogen doping efficiency are improved, moreover, a large amount of micropores, mesoporous and macropores can be generated, and the mass transfer efficiency of oxygen and water is improved. The method is simple and practical, the production cost is low, and the prepared catalyst has excellent oxygen reduction catalytic activity and can substitute the traditional commercial Pt / C catalyst.

Owner:重庆铈坦新材料技术研究院有限公司

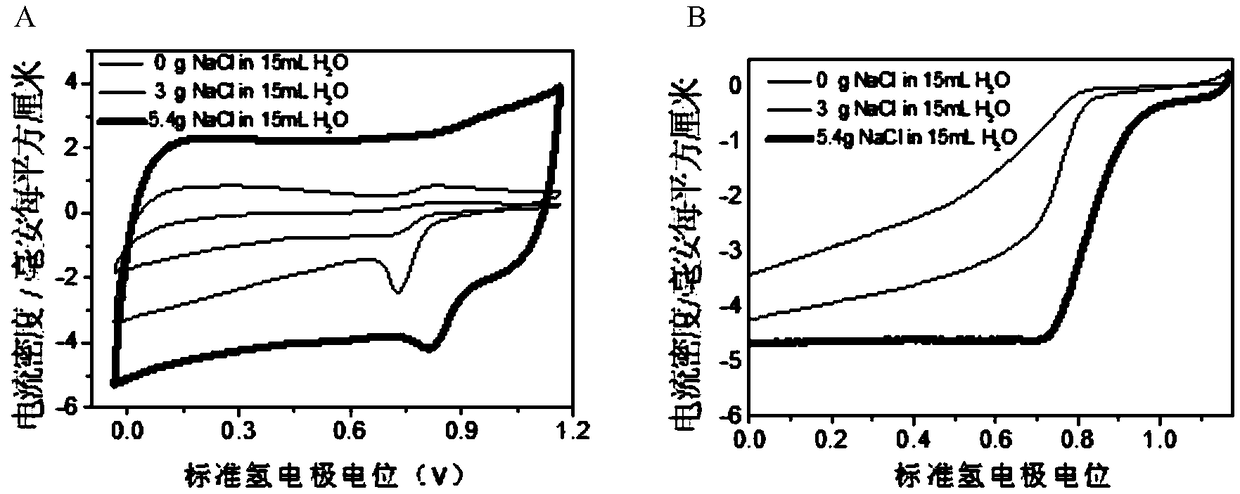

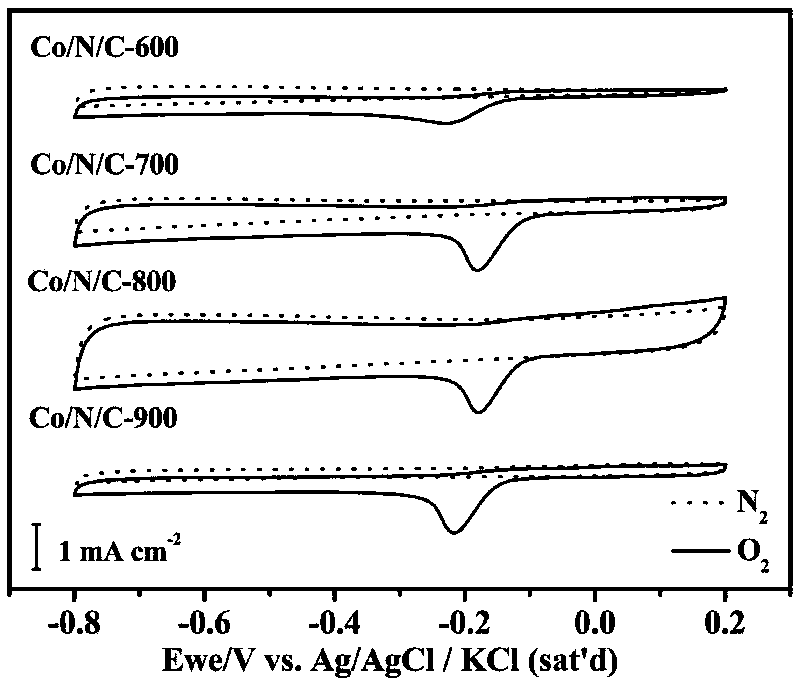

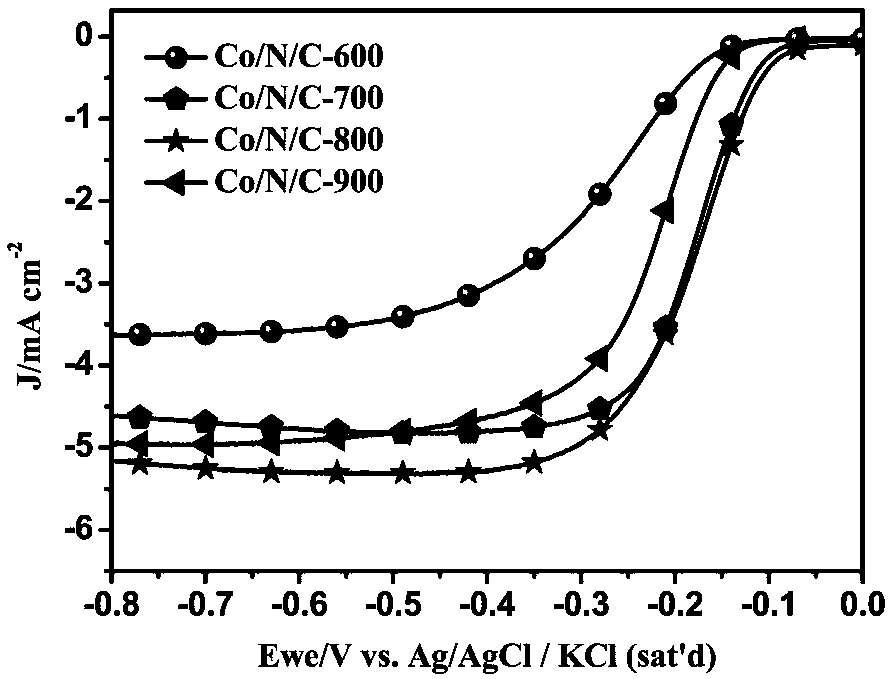

Cobalt-nitrogen co-doped porous carbon material and preparation and application thereof

InactiveCN108767272AImprove cycle stabilityImprove electrocatalytic performanceCell electrodesEnvironmental resistanceFreeze-drying

The invention relates to a cobalt-nitrogen co-doped porous carbon material, and preparation and application thereof. Riboflavin which is cheap, environmentally friendly and commercialized is simultaneously used as a carbon source and a nitrogen source. The riboflavin and cobalt acetate are dissolved into a saturated solution of sodium chloride that is a pore-forming agent at the same time, and then freeze-drying and carbonization are performed to obtain the cobalt-nitrogen co-doped porous carbon material. By utilization a pore-forming function of molten sodium chloride salt, a multi-stage porestructure is prepared, the carbon material having a special morphology can be prepared, and the oxygen reduction catalytic performance of the carbon material can be fully exerted. A simple route forpreparing a non-metal oxygen reduction catalytic material is provided and has a good application prospect.

Owner:DONGHUA UNIV

Carbon-based non-metallic oxygen reduction catalyst as well as preparation method and application thereof

ActiveCN104014367AThe content of the species is controllableStrong structural controllabilityCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsOxygenPt element

The invention belongs to the field of electrochemistry catalysis and particularly discloses a carbon-based non-metallic oxygen reduction catalyst as well as a preparation method and an application thereof. The carbon-based non-metallic oxygen reduction catalyst is a polymer which is prepared by doping other heteroatom (e.g. B, O, F, P, S, Cl, Br and I) derived from an N-contained polymerization product which is obtained by polymerizing aromatic nitrile compounds. The catalyst provided by the invention is high in conductivity, has a carbon skeleton structure with a high specific surface area and can be doped with many kinds of heteroatom. The catalyst has good oxygen reduction activity and high stability and is free from influence of methanol and carbon monoxide; besides, the catalyst is wide in application scope and is suitable for various systems containing oxygen reduction reaction, including a lithium air cell, a sodium air cell, kinds of fuel cells and so on; compared with an existing commercial platinum carbon (Pt / C) catalyst, the catalyst has the advantage of simple preparation, efficiency, environment friendliness, low cost and excellent performance.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

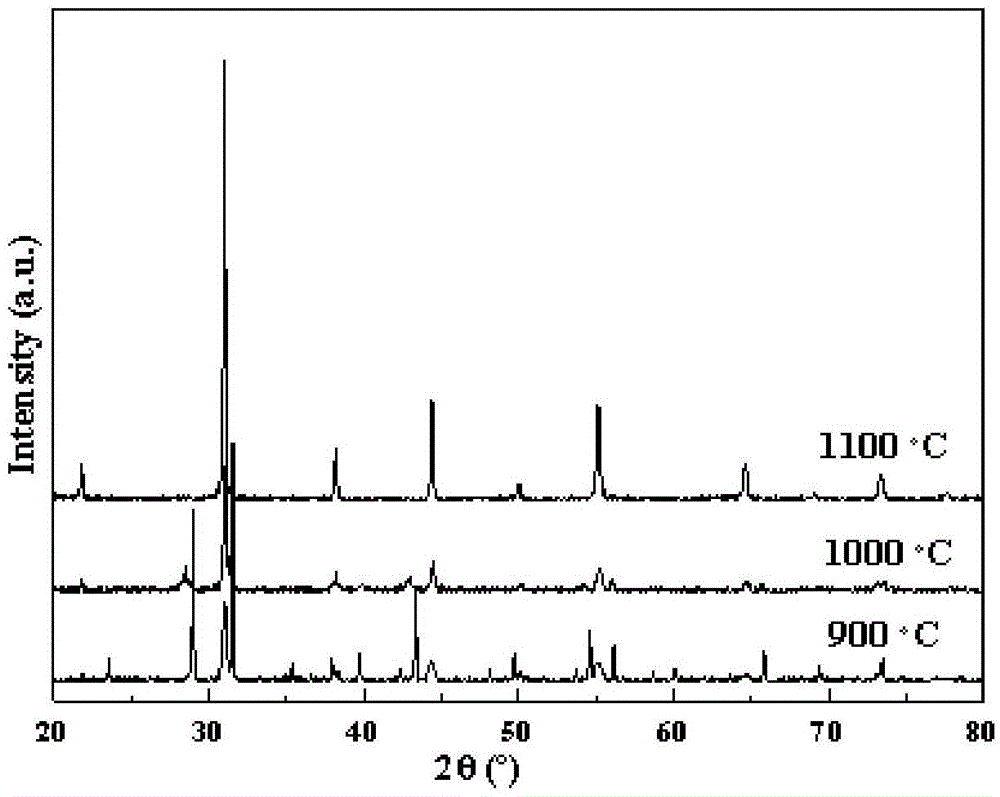

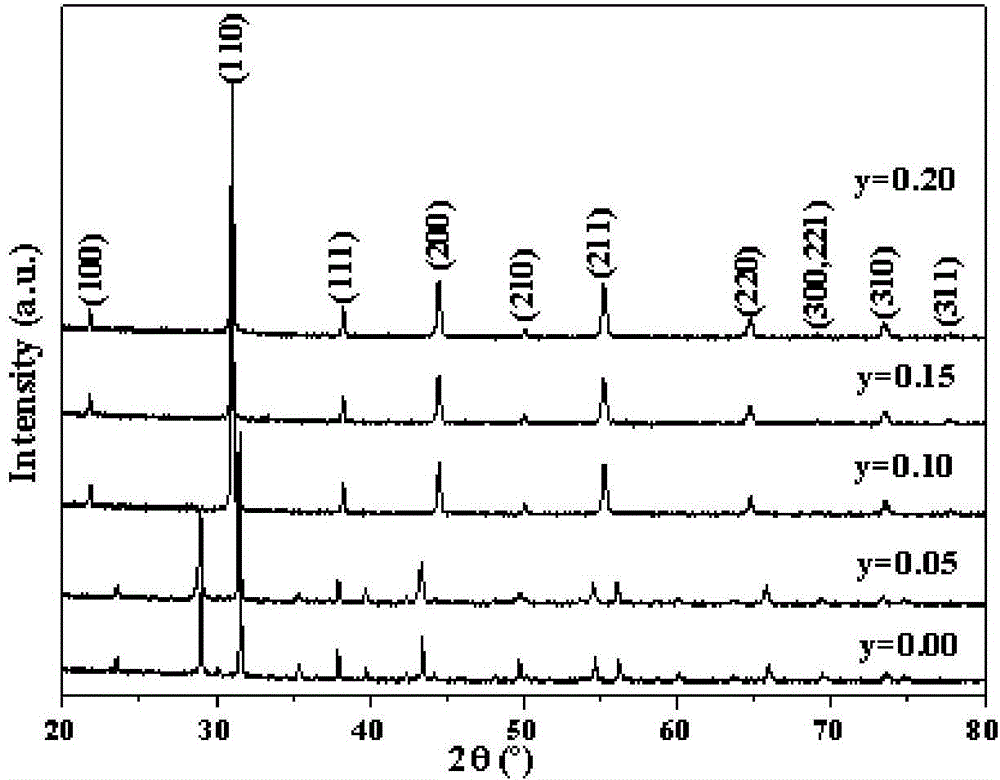

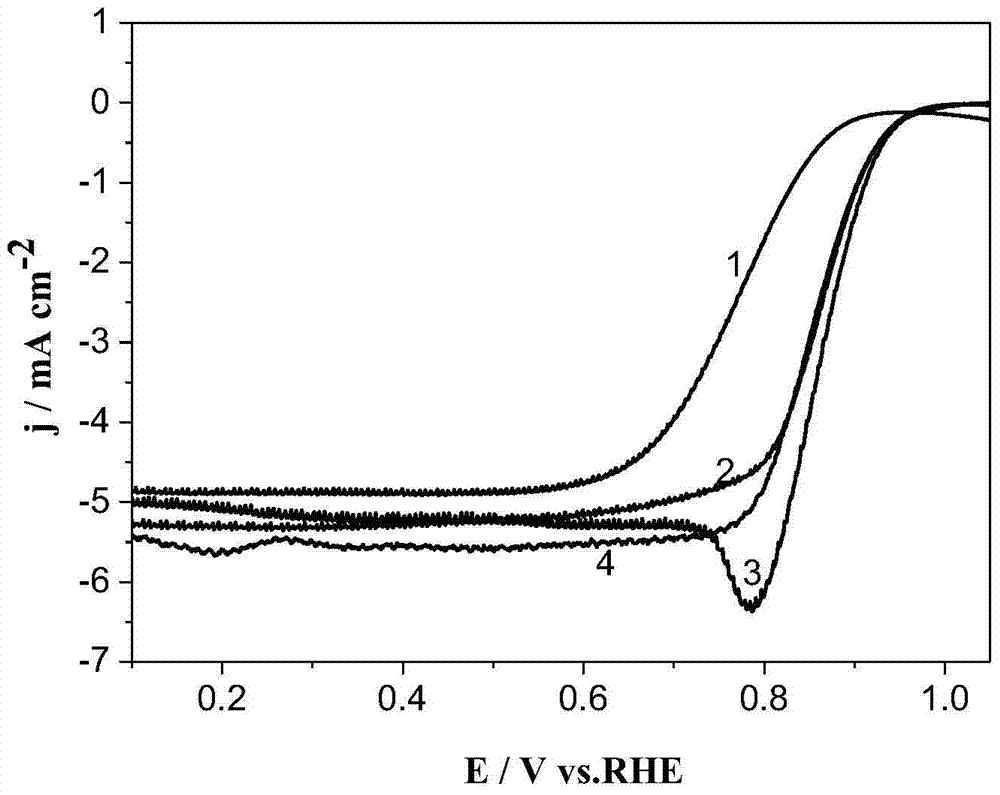

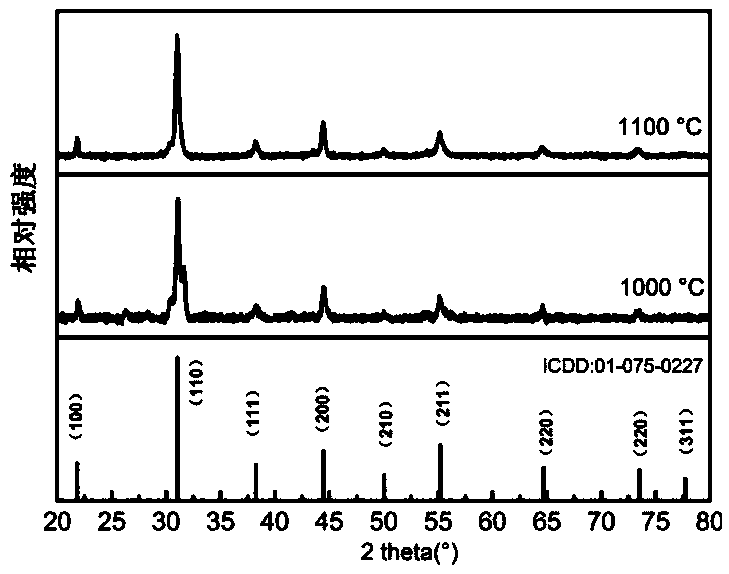

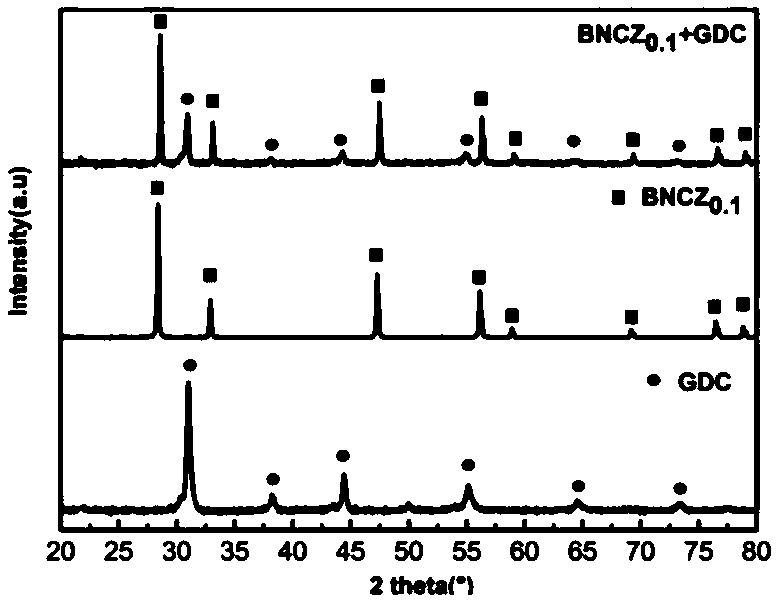

BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, preparation method and applications thereof

InactiveCN104409742AImprove structural stabilityCo-doping improvesCell electrodesOxygen ionsChemical compatibility

The invention discloses a BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, a preparation method and applications thereof. The provided cathode material has a perovskite type structure and is represented by a chemical formula: BaBi<x>Nb<y>Co<1-x-y>O<3-delta>, wherein the delta represents oxygen excess or oxygen deficiency (-1=<delta=<1), the x represents the doping amount of Bi2O3 (0=<x=<0.15), and the y represents the doping amount of Nb2O5 (0=<y=<0.2). The chemical compatibility between the provided BaBi<x>Nb<y>Co<1-x-y>O<3-delta> cathode material and the conventional electrolyte material such as GDC, and the like is good. In the air the current can be well conducted by the oxygen ions and electrons. In the temperature range of 450 to 850 DEG C, the provided cathode material has a very good oxidation-reduction catalytic activity. The cathode material is suitable for a solid oxide fuel cell used at a mid-low temperature.

Owner:HARBIN INST OF TECH

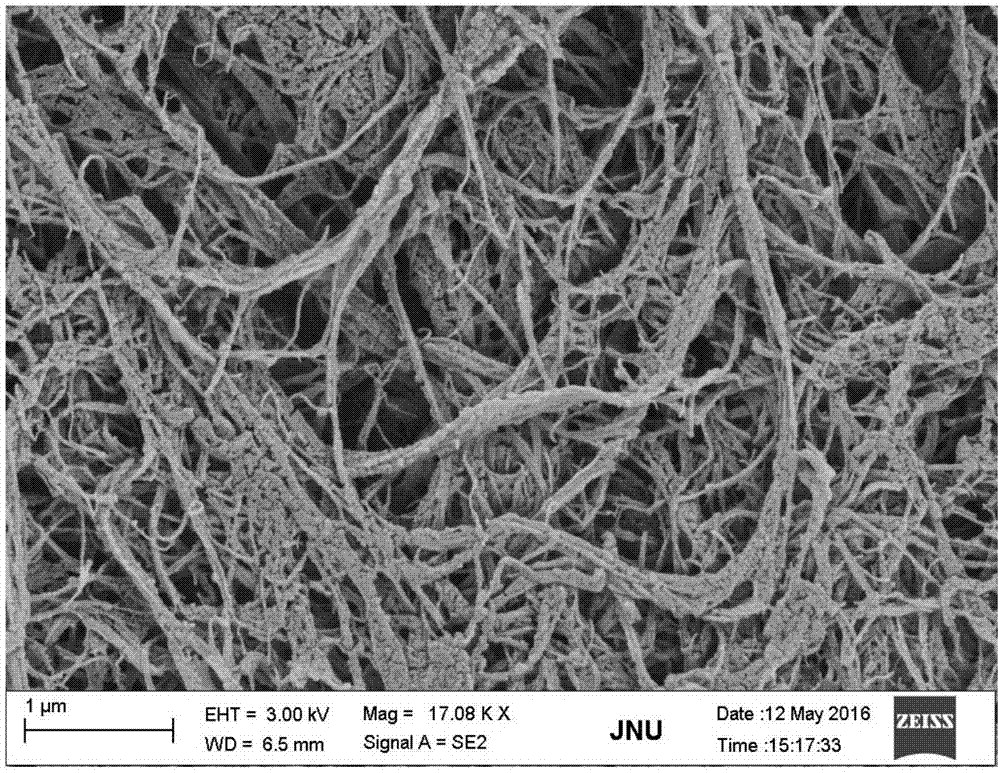

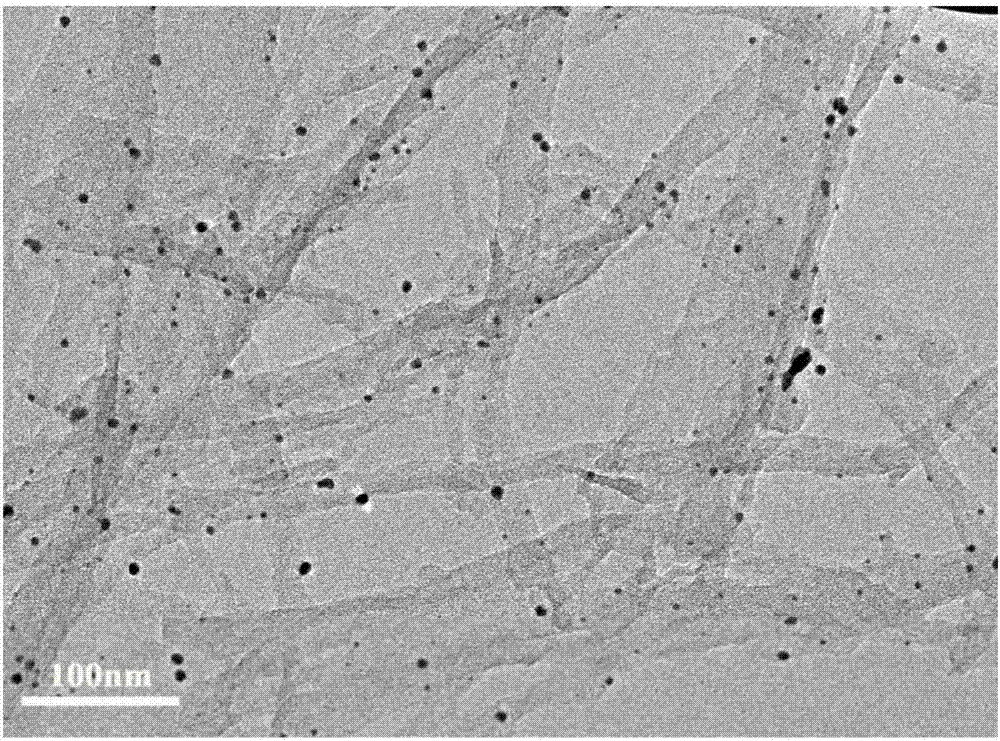

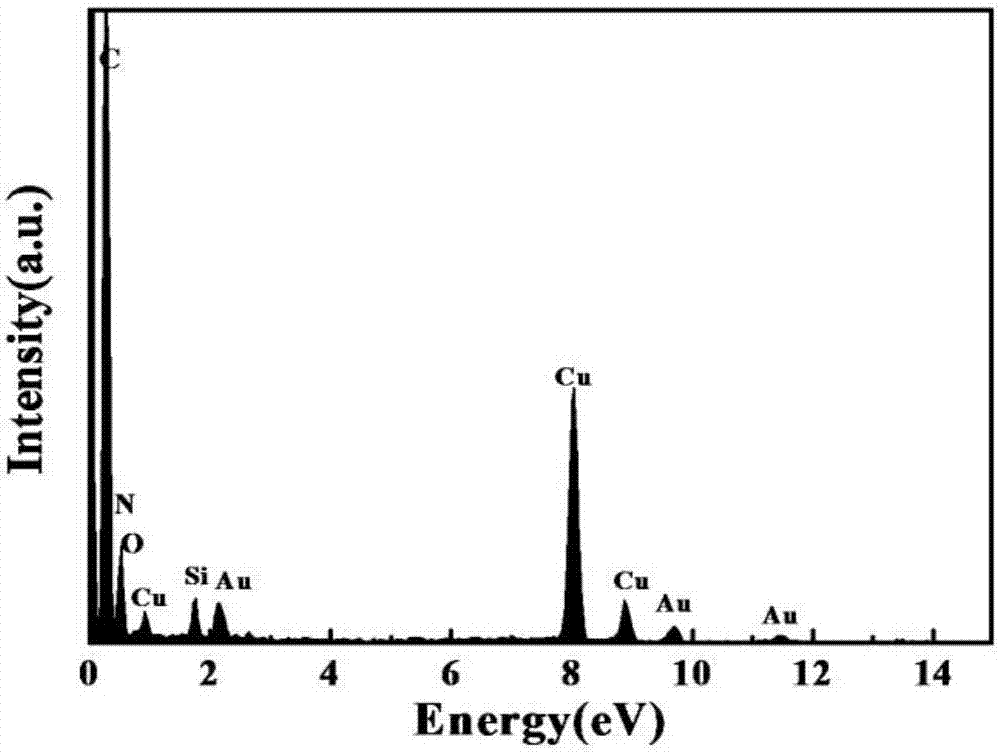

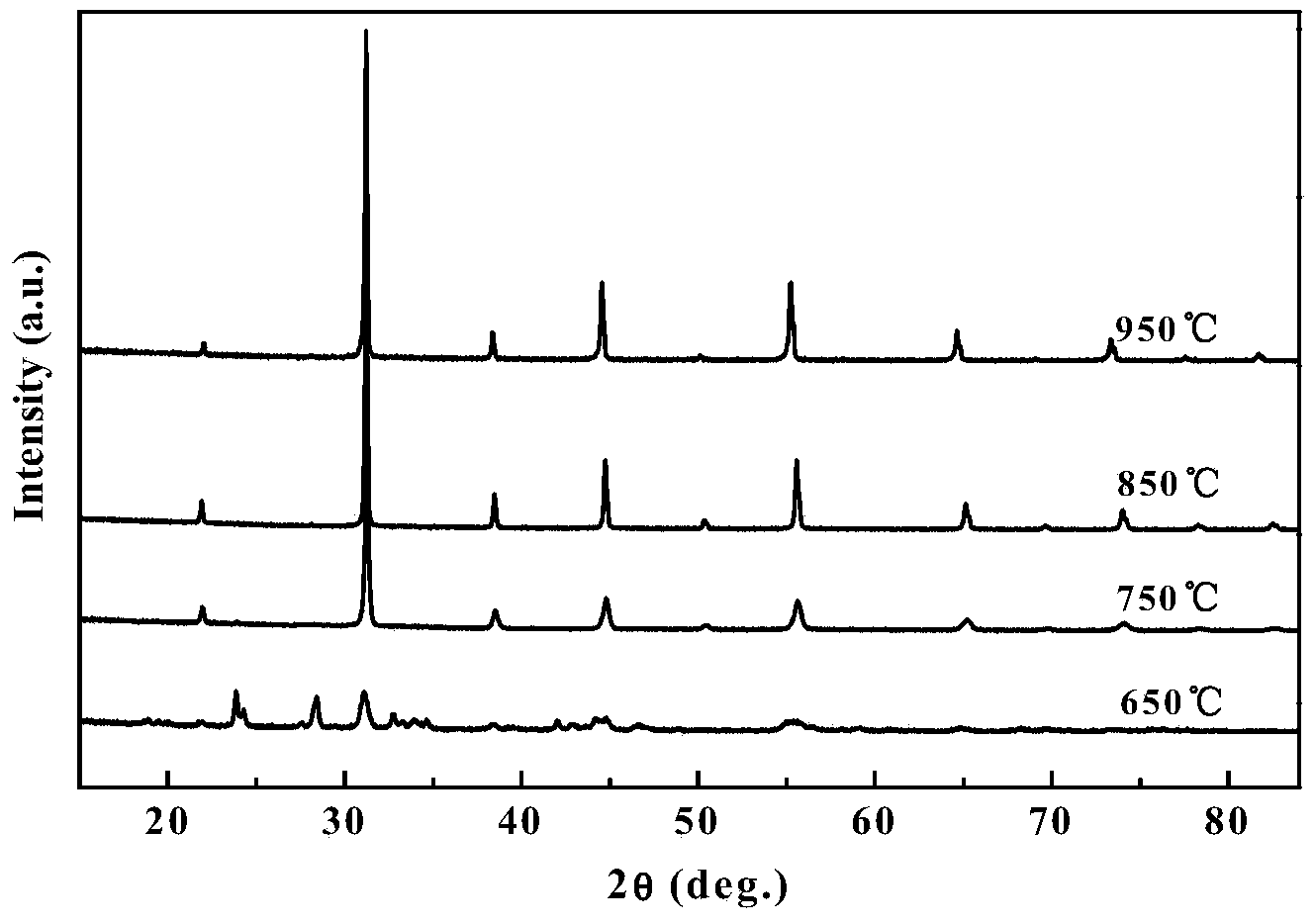

Preparation method of nitrogen-doped carbon nanofiber loaded gold nanoparticle oxygen reduction catalyst

InactiveCN107331876AFacilitated DiffusionEasy to fillMaterial nanotechnologyCell electrodesWater bathsFreeze-drying

The invention discloses a preparation method of a nitrogen-doped carbon nanofiber loaded gold nanoparticle oxygen reduction catalyst. The preparation method comprises the following steps: soaking bacterial cellulose into deionized water until the bacterial cellulose is neutral, draining off water, adding a dopamine solution, stirring in a constant-temperature water bath at 50 DEG C, adding a Tri-HCl buffer solution with a pH value of 8.5, and continuing to stir, so as to finally obtain a bacterial cellulose and dopamine compound; and carrying out freeze drying on the bacterial cellulose and dopamine compound, putting the compound into a tubular furnace, carrying out high-temperature carbonization so as to obtain nitrogen-doped carbon nanofibers, and loading the nitrogen-doped carbon nanofibers with gold nanoparticles by virtue of a sodium borohydride chemical reduction method, so as to obtain the nitrogen-doped carbon nanofiber loaded gold nanoparticle oxygen reduction catalyst. The preparation method of the catalyst is simple, and the oxygen reduction property of the catalyst is excellent under alkali conditions. Compared with a Pt catalyst, the catalyst is relatively low in cost and good in stability.

Owner:佛山市利元合创科技有限公司

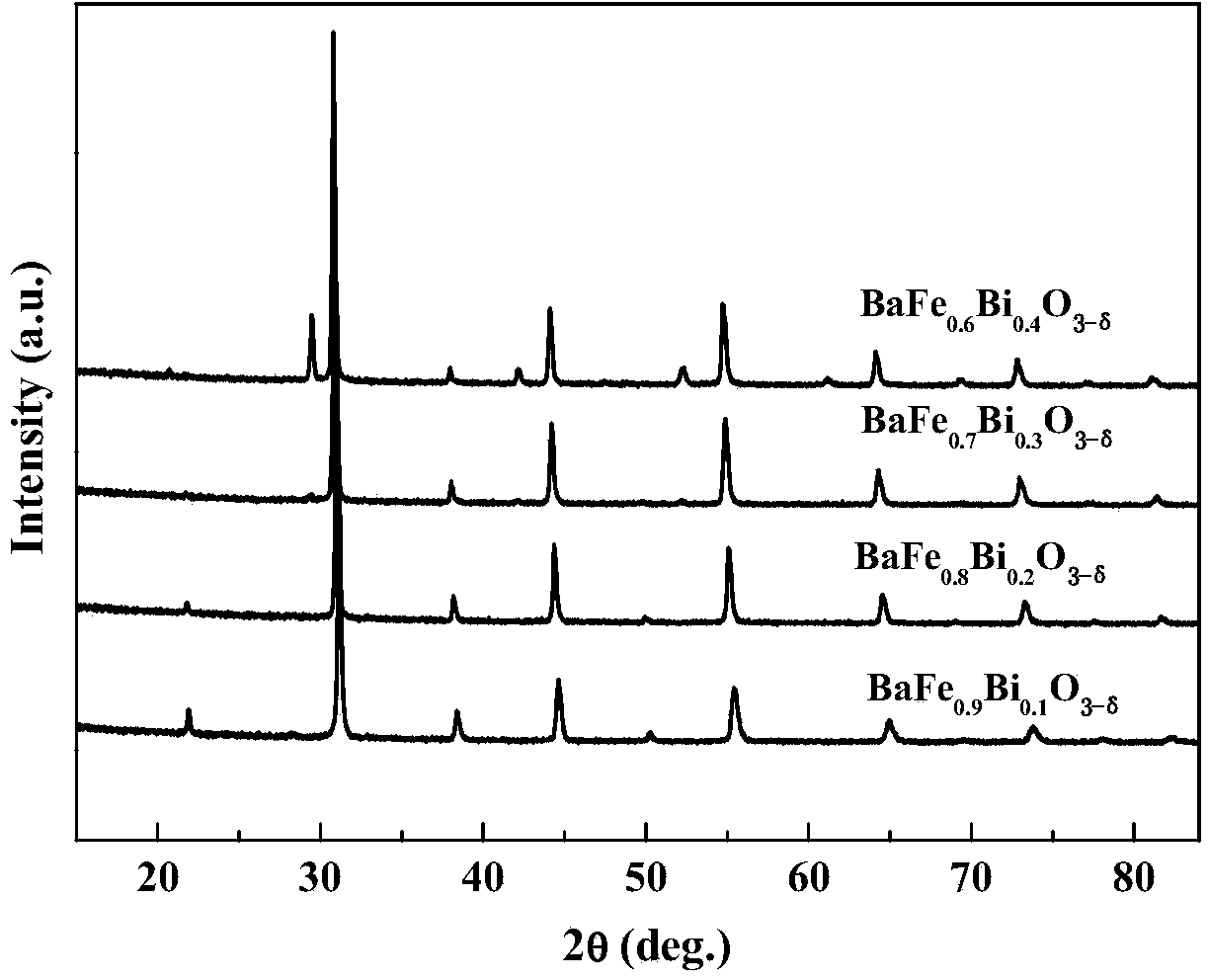

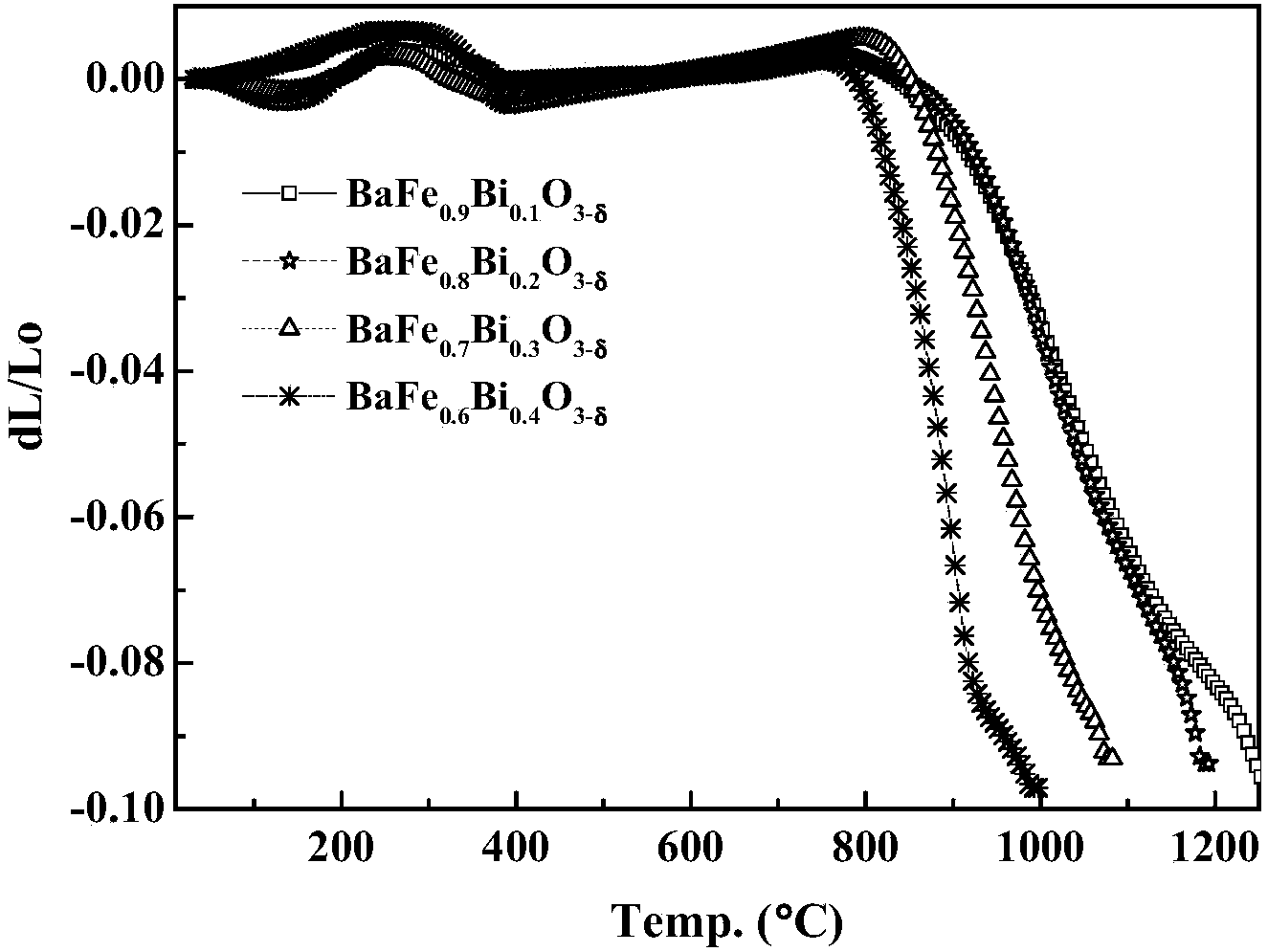

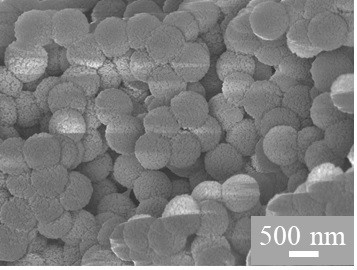

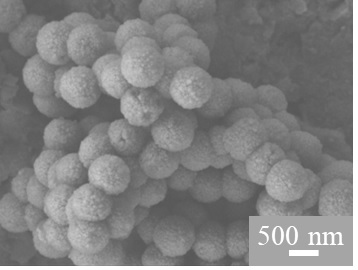

BaFeO3-theta-base B-site Bi2O3 doping solid oxide fuel cell cathode material as well as preparation method and application thereof

InactiveCN103985880AGood thermal expansion coefficient matchingGood chemical compatibilityCell electrodesSolid electrolyte fuel cellsFuel cellsSolid reaction

The invention discloses a BaFeO3-theta-base B-site Bi2O3 doping solid oxide fuel cell cathode material as well as a preparation method and an application thereof. The constitutional molecular formula of the cathode material is BaFe<1-x>BixO<3-theta>, wherein theta indicates the excessive oxygen quantity or the shortage quantity of oxygen, theta is more than or equal to minus 1 and less than or equal to 1, x indicates the doping quantity of Bi2O3, and x is more than or equal to 0 and less than or equal to 0.5. The BaFeO3-theta-base B-site Bi2O3 doping solid oxide fuel cell cathode material can be synthesized in a solid reaction method and also can be synthesized in a sol-gel method. The invention also provides an application of BaFe<1-x>BixO<3-theta> in a low-temperature solid oxide fuel cell. A BaFeO3-theta perovskite cathode material is doped with Bi2O3 on B site, so that the electrochemical performance of the material can be improved, and the SOFC (solid oxide fuel cell) cathode material with good electrochemical performance, stable structure and appropriate heat expansion coefficient can be obtained.

Owner:HARBIN INST OF TECH

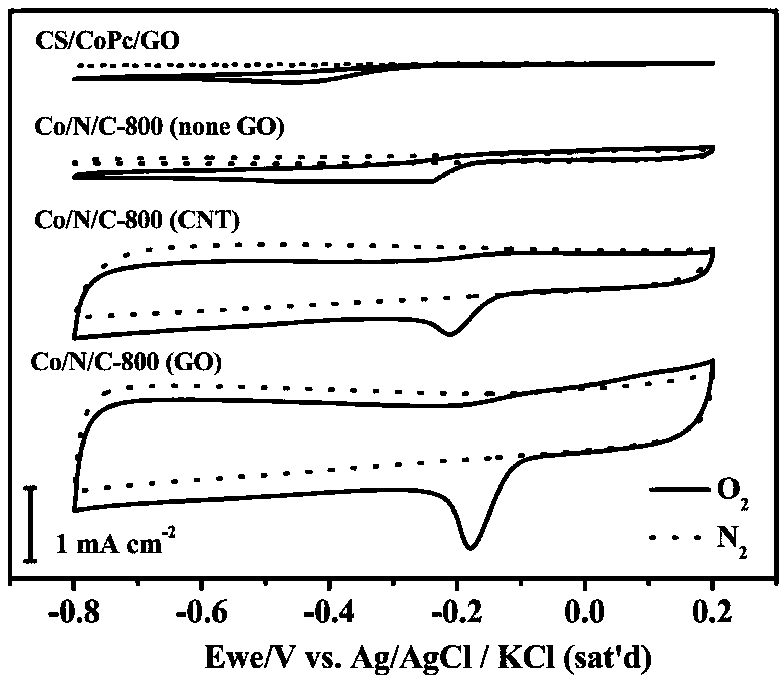

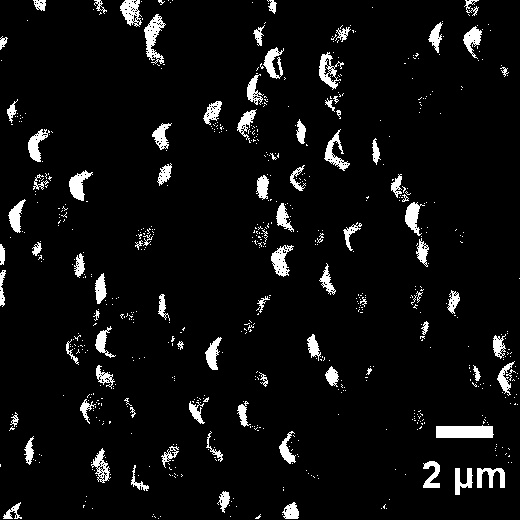

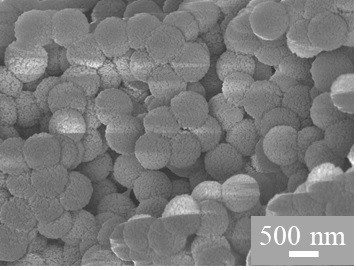

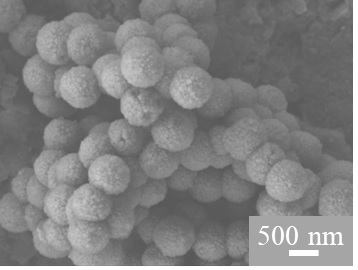

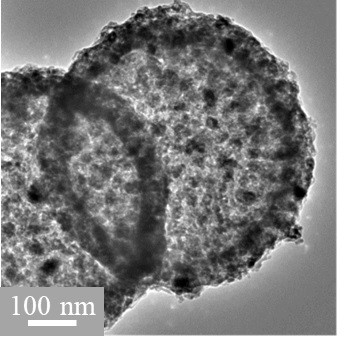

Hollow-structured transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst as well as preparation method and application thereof

ActiveCN112038648ARich reservesThe preparation process is simple and controllableCell electrodesNanotechnologyPtru catalystMicrosphere

The invention relates to a hollow-structured transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst as well as a preparation method and application thereof. A zeolite imidazatemetal organic framework material grows on the surface of a template by utilizing electrostatic interaction between sulfonic acid groups on the surfaces of microspheres and metal cobalt ions, and thenthe zeolite imidazate metal organic framework material is prepared by pyrolysis and carbonization in an inert atmosphere. According to the method provided by the invention, the active site utilization rate of the transition metal cobalt and nitrogen co-doped carbon catalyst can be effectively improved, the prepared catalyst can efficiently catalyze the oxygen reduction reaction of the cathode ofthe fuel cell, and the oxygen reduction catalytic activity is superior to that of commercial Pt / C.

Owner:BEIJING UNIV OF CHEM TECH

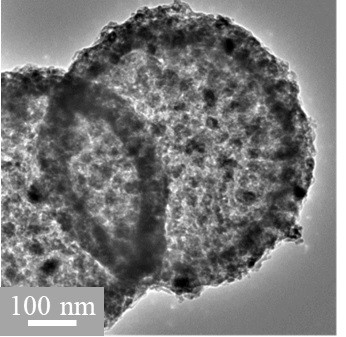

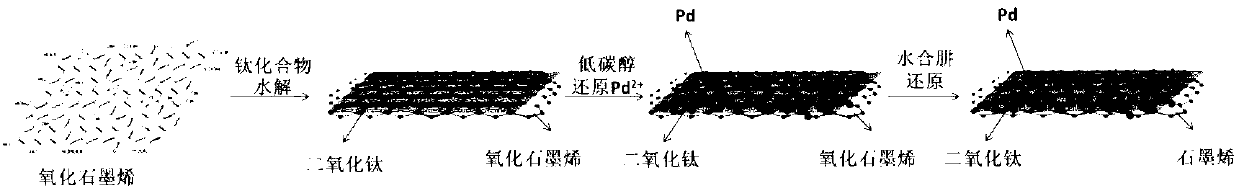

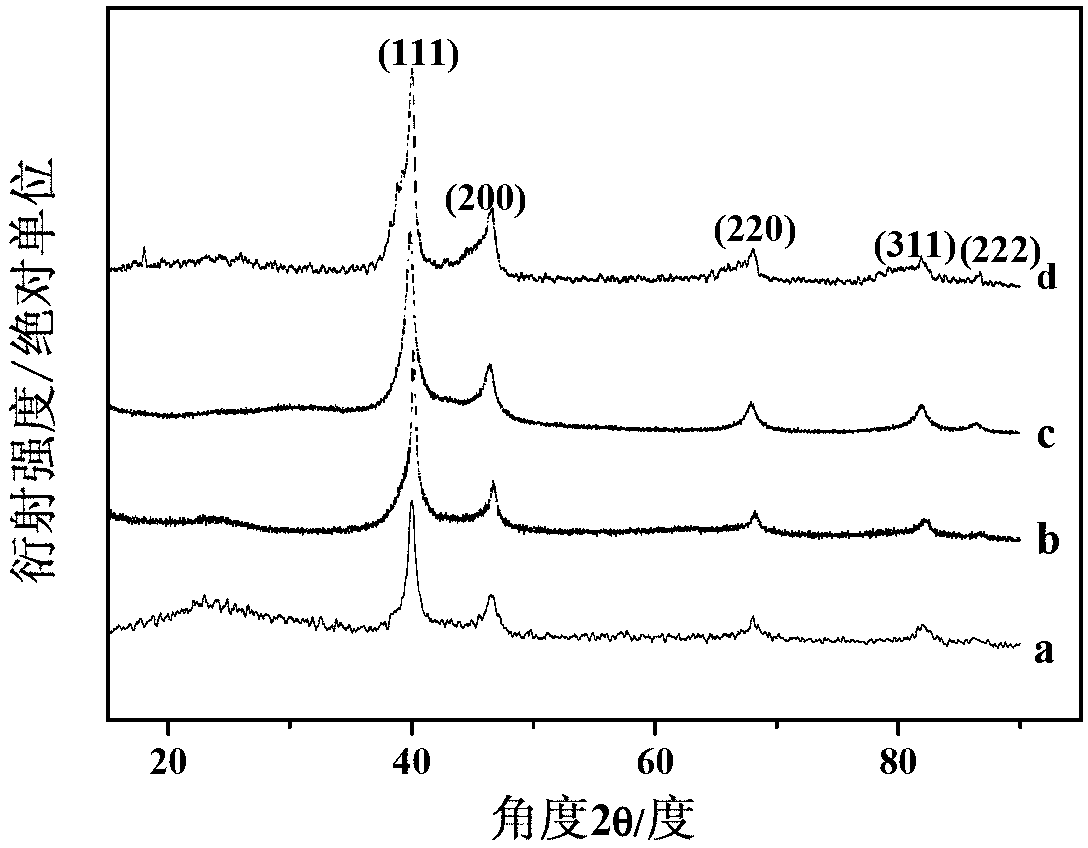

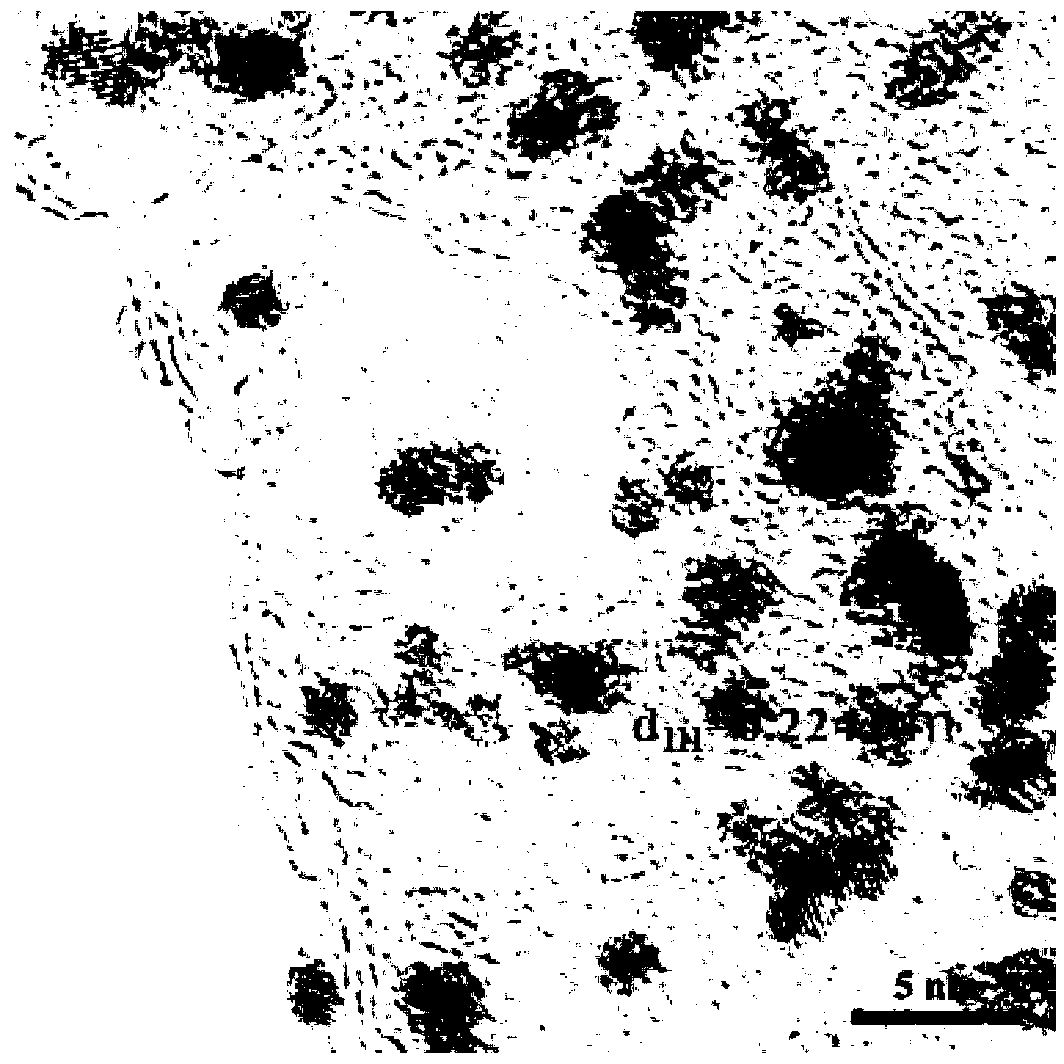

Palladium/titanium dioxide/graphene catalyst and preparation method thereof

InactiveCN103346331AImprove corrosion resistanceHigh catalytic activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsOxygenHydrolysis

The invention relates to a palladium / titanium dioxide / graphene catalyst and a preparation method thereof, belonging to the technical field of electrocatalysts. The catalyst comprises chemical components of Pd / TiO2 / G, wherein G is the graphene, the TiO2 / G is a catalyst carrier, the amorphous state TiO2 is uniformly covered on the surface of G, so that the corrosion resistance of G is improved, and the electrical conductivity of the TiO2 is improved by G,; the grain size of the catalytic activity component Pd is 2-4 nanometer, the Pd are uniformly distributed on the surface of the TiO2 / G carrier. The catalyst has good electro-catalysis oxygen reduction activity, methyl alcohol resistance and stability. The preparation method of the catalyst comprises the following steps of uniformly covering the amorphous state TiO2 on the G through titanium compound hydrolysis so as to prepare a TiO2 / G composite carrier, and loading the Pd particles on the TiO2 / G composite carrier through low carbon alcohol reducing action, so as to prepare the Pd / TiO2 / G catalyst. The preparation method has the characteristics of being simple in technology, easy to operate and the like.

Owner:BEIJING UNIV OF CHEM TECH

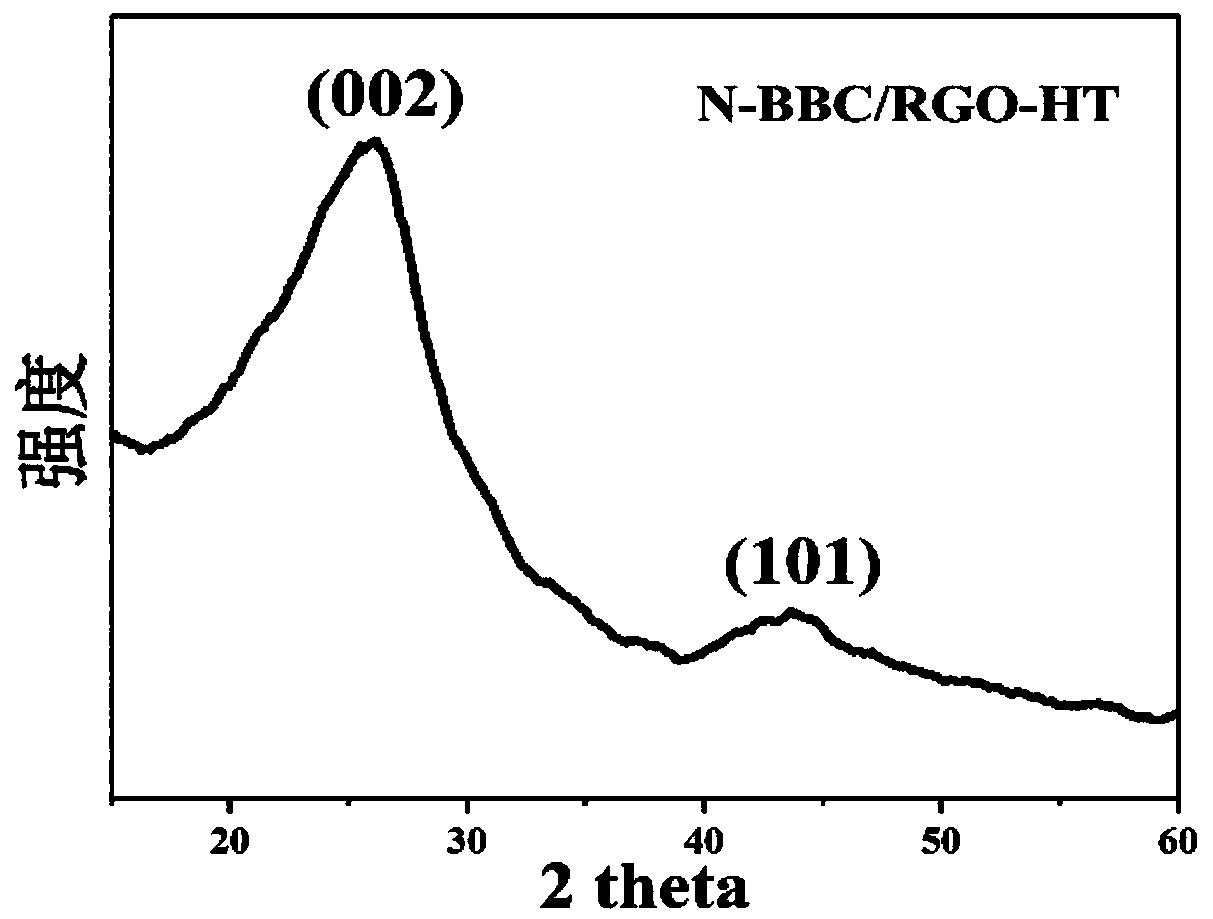

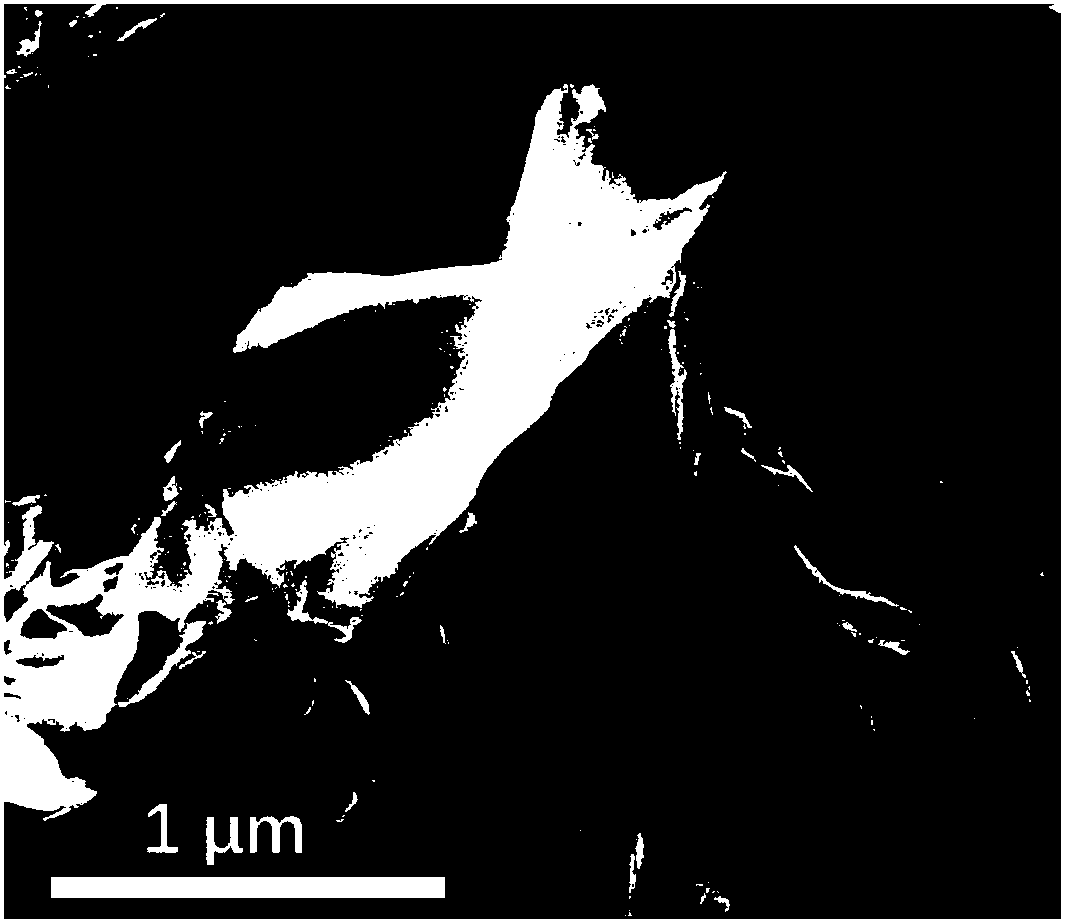

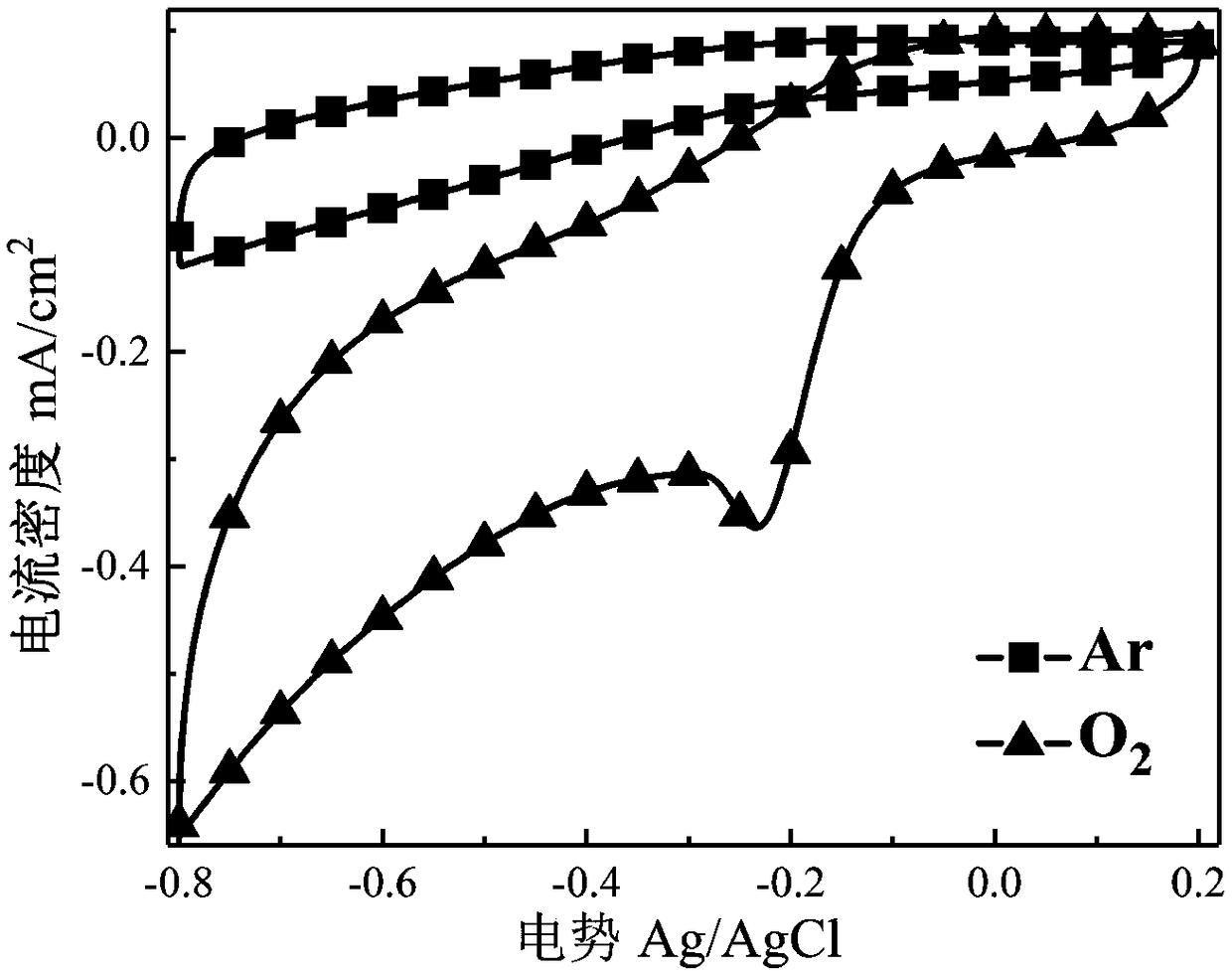

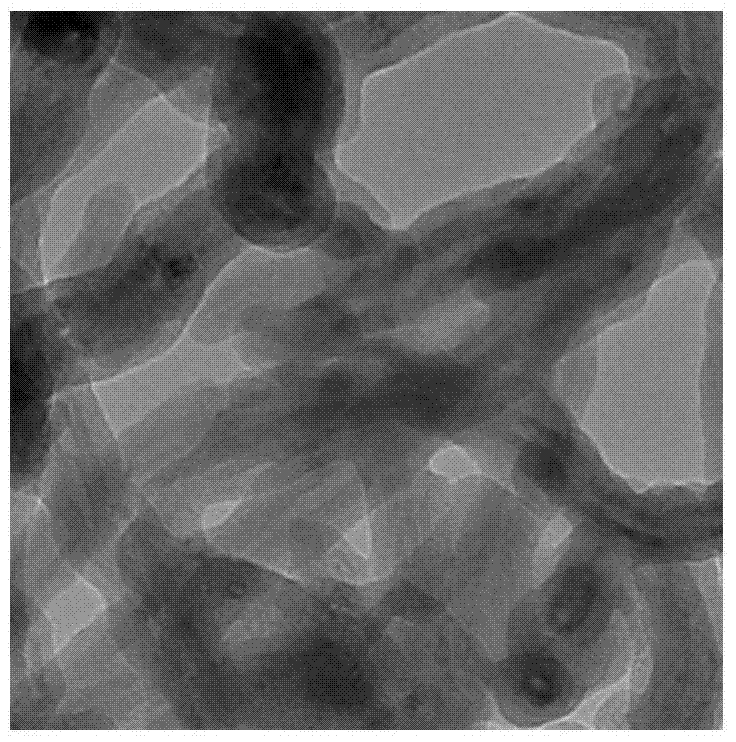

Soybean biological base fuel cell oxygen reduction catalyst and preparation method and application thereof

InactiveCN108448124AIncrease the number of layersMany layersCell electrodesFuel cellsFuel cellsCarbonization

The invention discloses a soybean biological base fuel cell oxygen reduction catalyst and a preparation thereof. The preparation method comprises the following steps of 1) preparing graphene oxide; 2)taking graphene oxide as a carrier and taking soybean as a carbon source, performing carbonization treatment through a hydrothermal method to obtain a precursor; and 3) performing pyrolysis and reduction on the precursor in an ammonia gas atmosphere to obtain the soybean biological base fuel cell oxygen reduction catalyst. The soybean biological base fuel cell oxygen reduction catalyst is used for catalyzing an oxygen reduction reaction of a fuel cell. The soybean biological base fuel cell oxygen reduction catalyst is prepared through a simple method by taking low-cost natural biomass soybeanas the raw material and by taking graphene as the carrier for performing pyrolysis and reduction in the ammonia gas atmosphere at a temperature of 800 DEG C. The catalyst is excellent in oxygen reduction performance and can be widely applied to the fuel cell.

Owner:UNIV OF JINAN

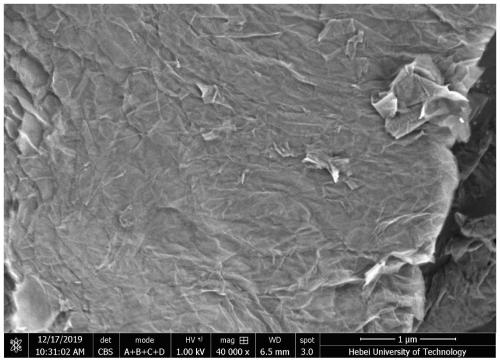

Preparation method and application of ionic liquid modified nitrogen-sulfur co-doped graphene oxide composite material

ActiveCN111229310AImprove electronic performanceHigh chemical activityOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesDoped graphenePtru catalyst

The invention relates to a preparation method of an ionic liquid modified nitrogen-sulfur co-doped graphene oxide composite material. The method comprises the following steps: preparing a dispersion liquid from graphene oxide and deionized water, then mixing 1-aminopropyl-3-alkyl imidazole bromide salt, potassium hydroxide and the graphene oxide dispersion liquid, carrying out a reaction process to obtain a 1-aminopropyl-3-alkyl imidazole bromide salt and graphene oxide composite product, then mixing the product with thiourea, adding a solvent to dissolve the mixture, and reacting at 160-200 DEG C to obtain the composite material. The composite material is loaded on a cathode electrode to serve as a catalyst. The material obtained by the invention has good oxygen reduction catalytic activity and a wide application prospect.

Owner:HEBEI UNIV OF TECH

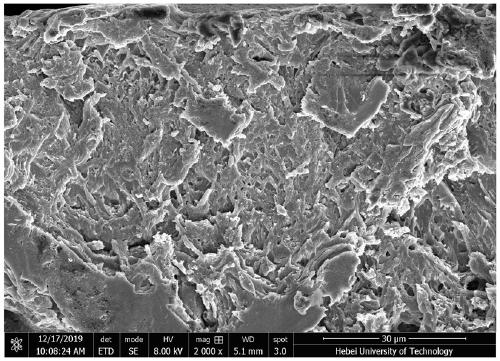

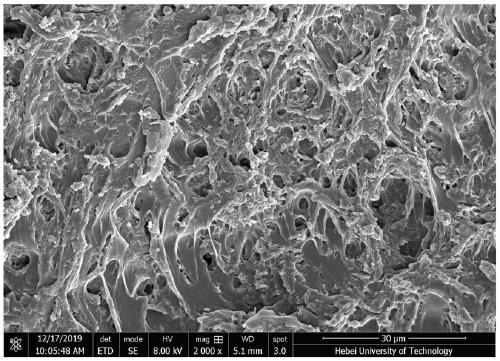

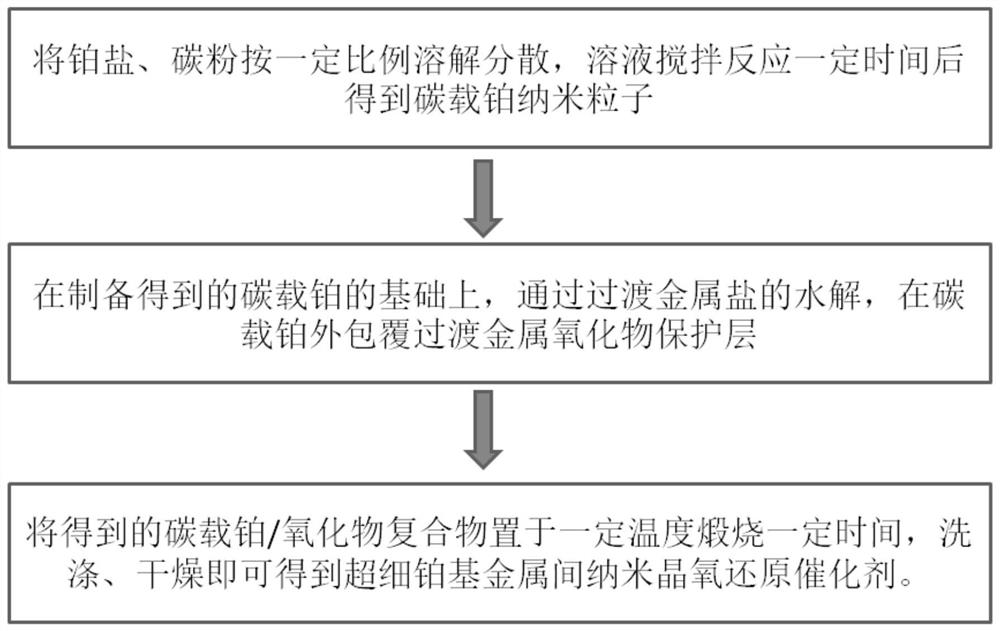

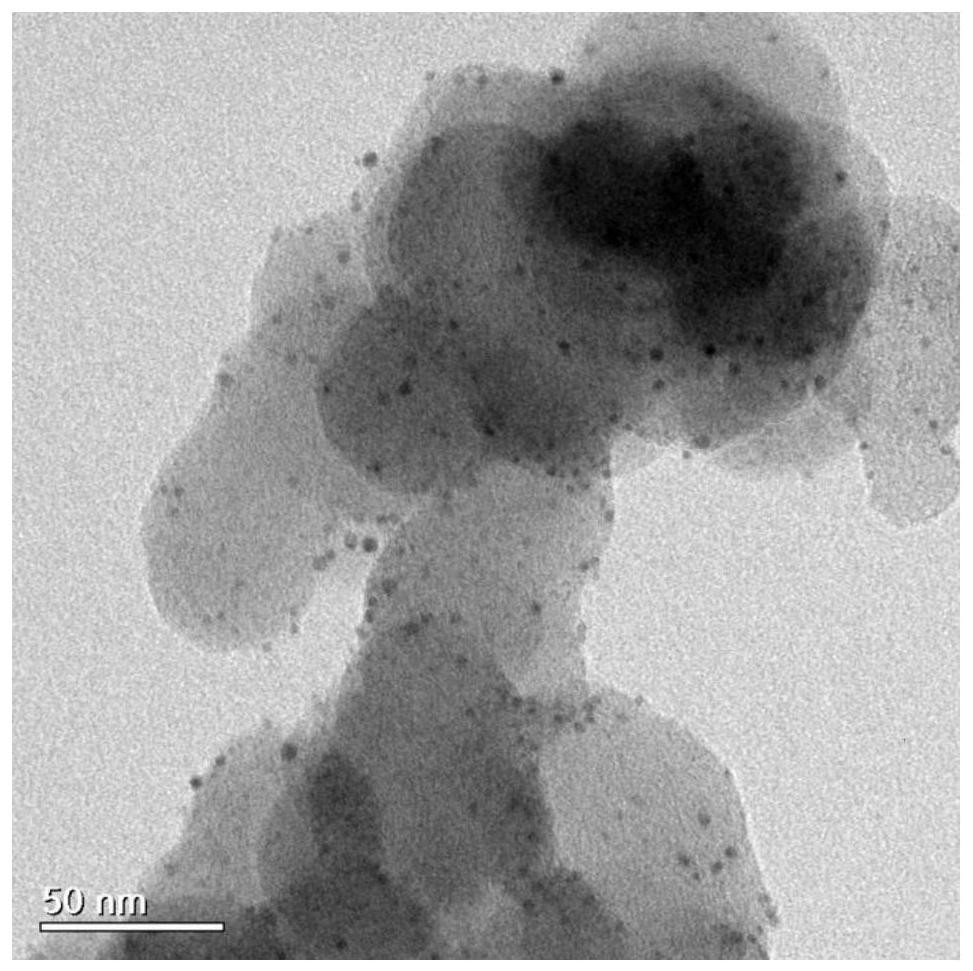

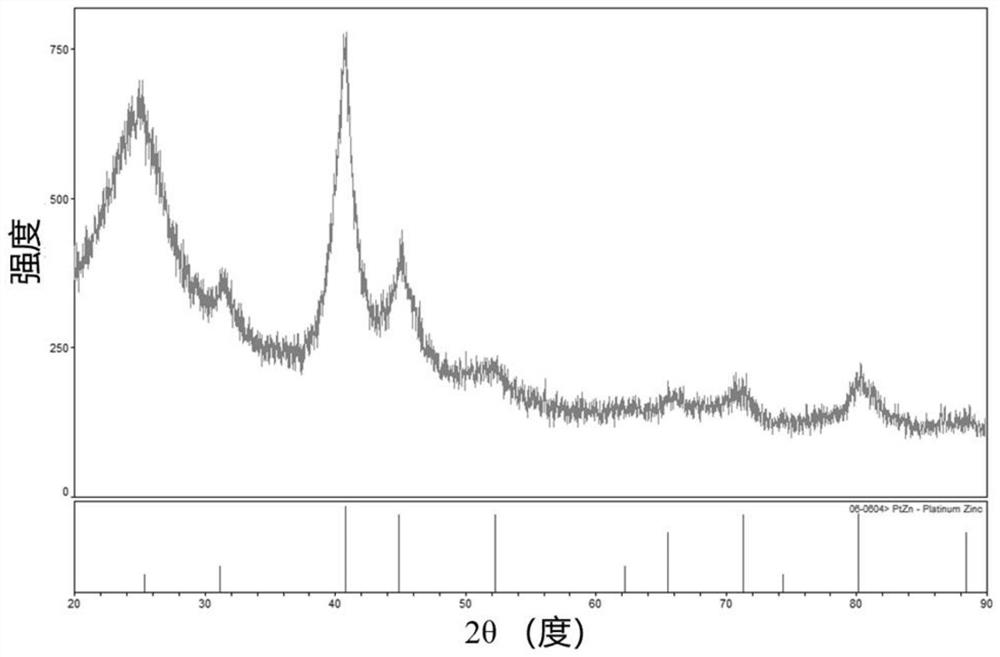

Platinum-based intermetallic nanocrystal with ordered structure and preparation and application thereof

ActiveCN113206259ARaise the chemical potentialEasy to driveCell electrodesPlatinum saltsPtru catalyst

Owner:HUAZHONG UNIV OF SCI & TECH

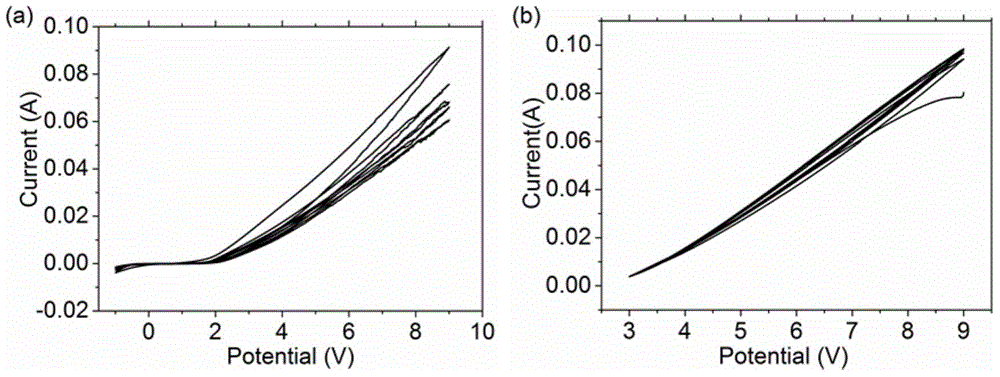

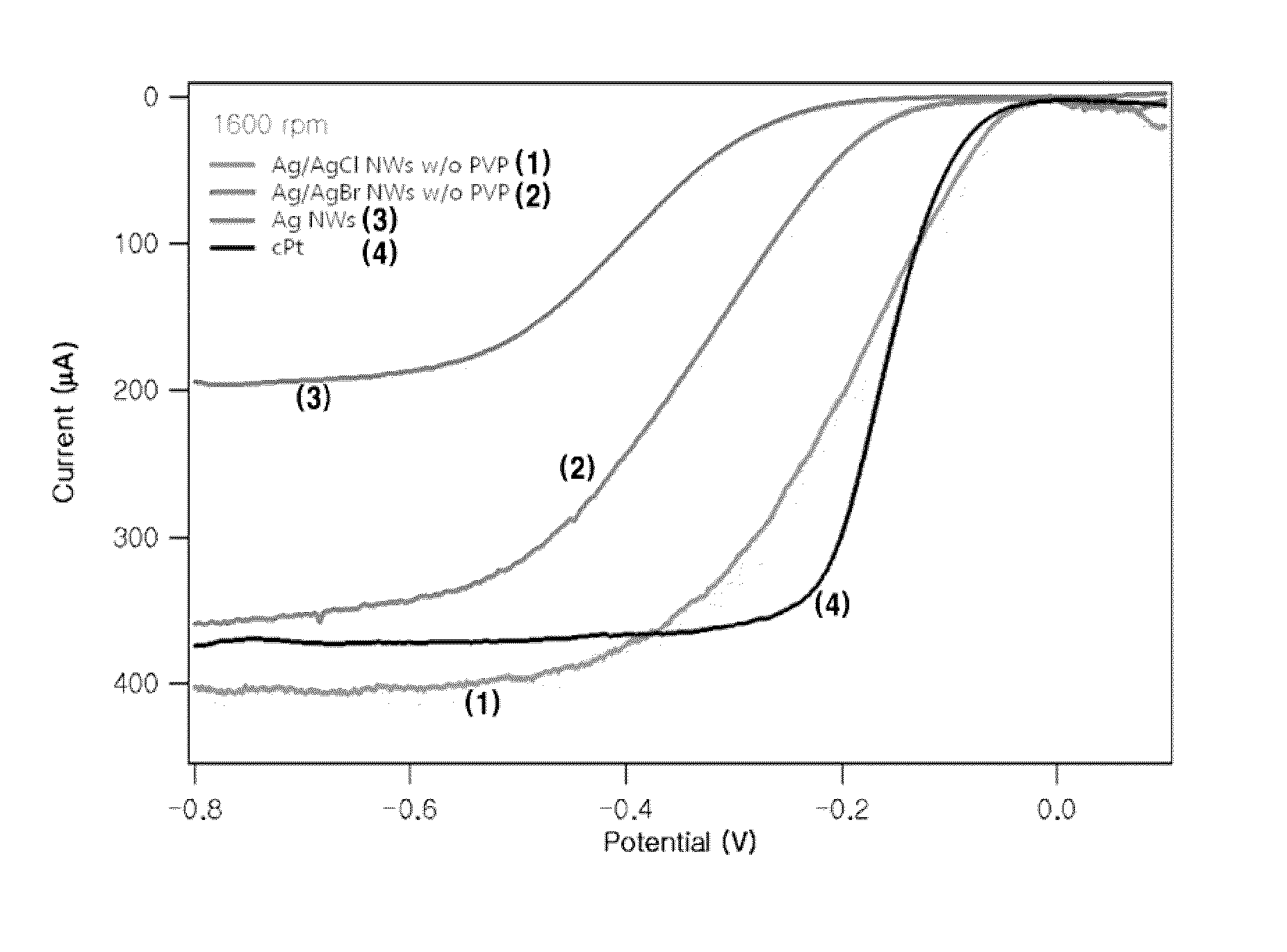

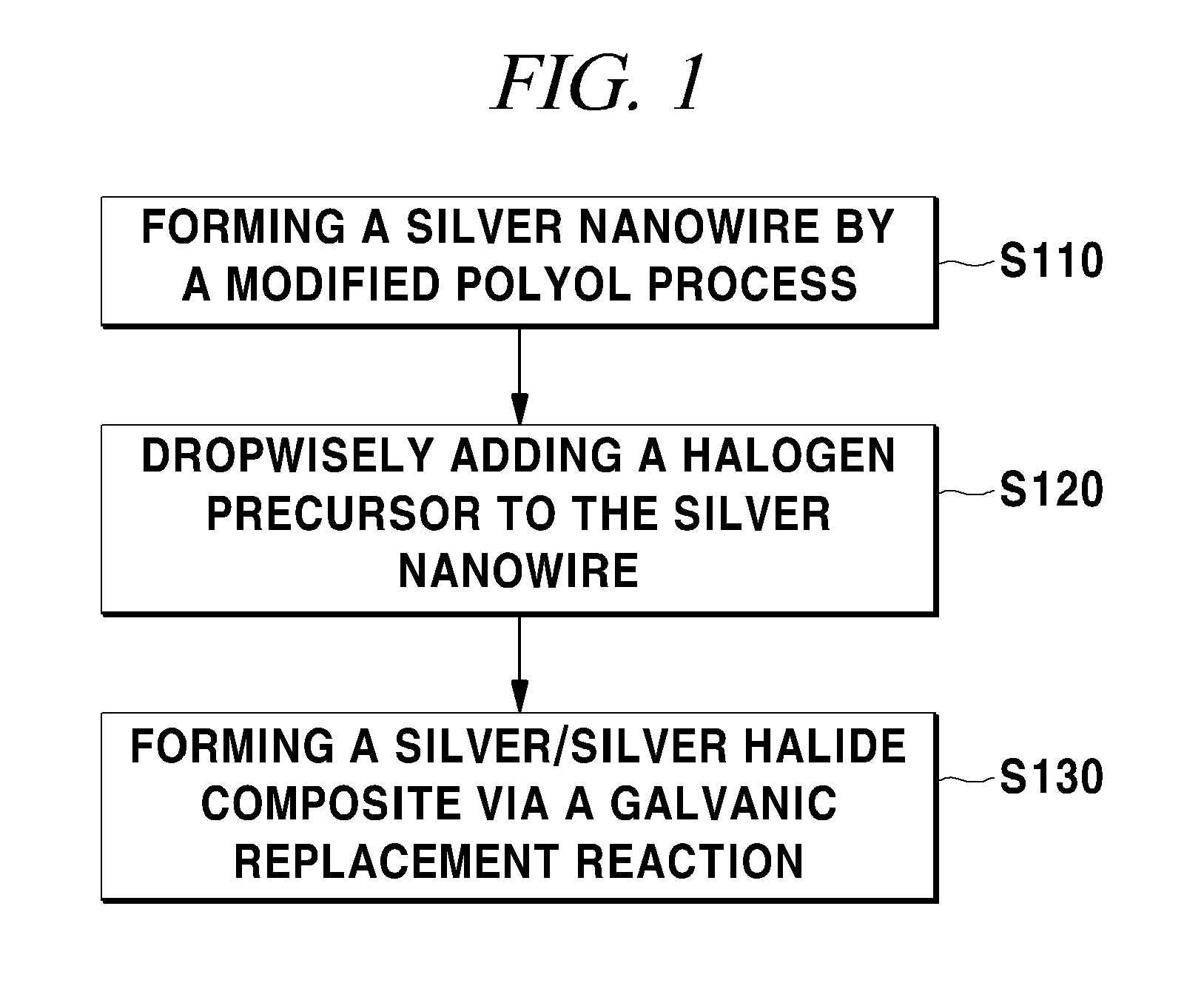

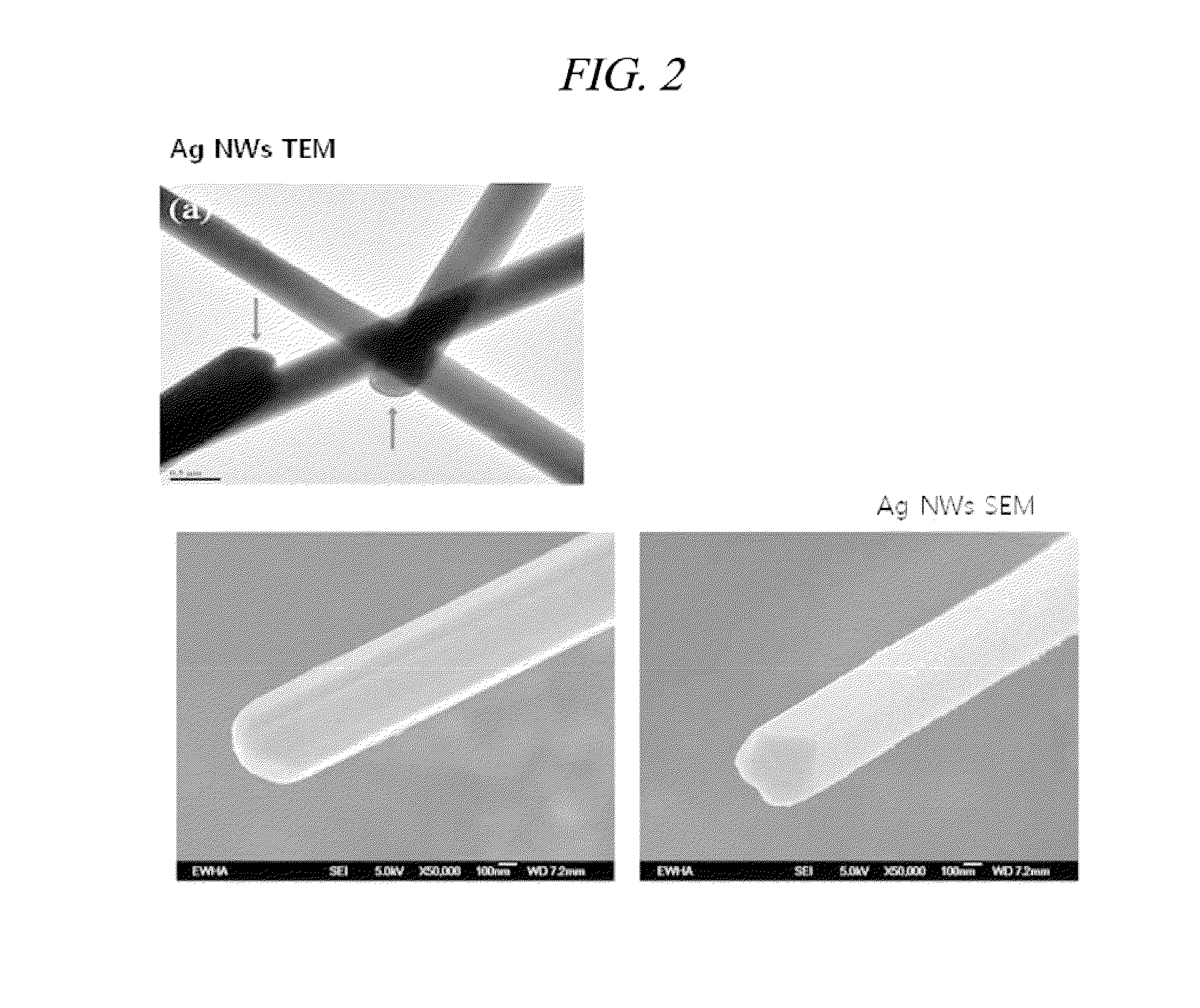

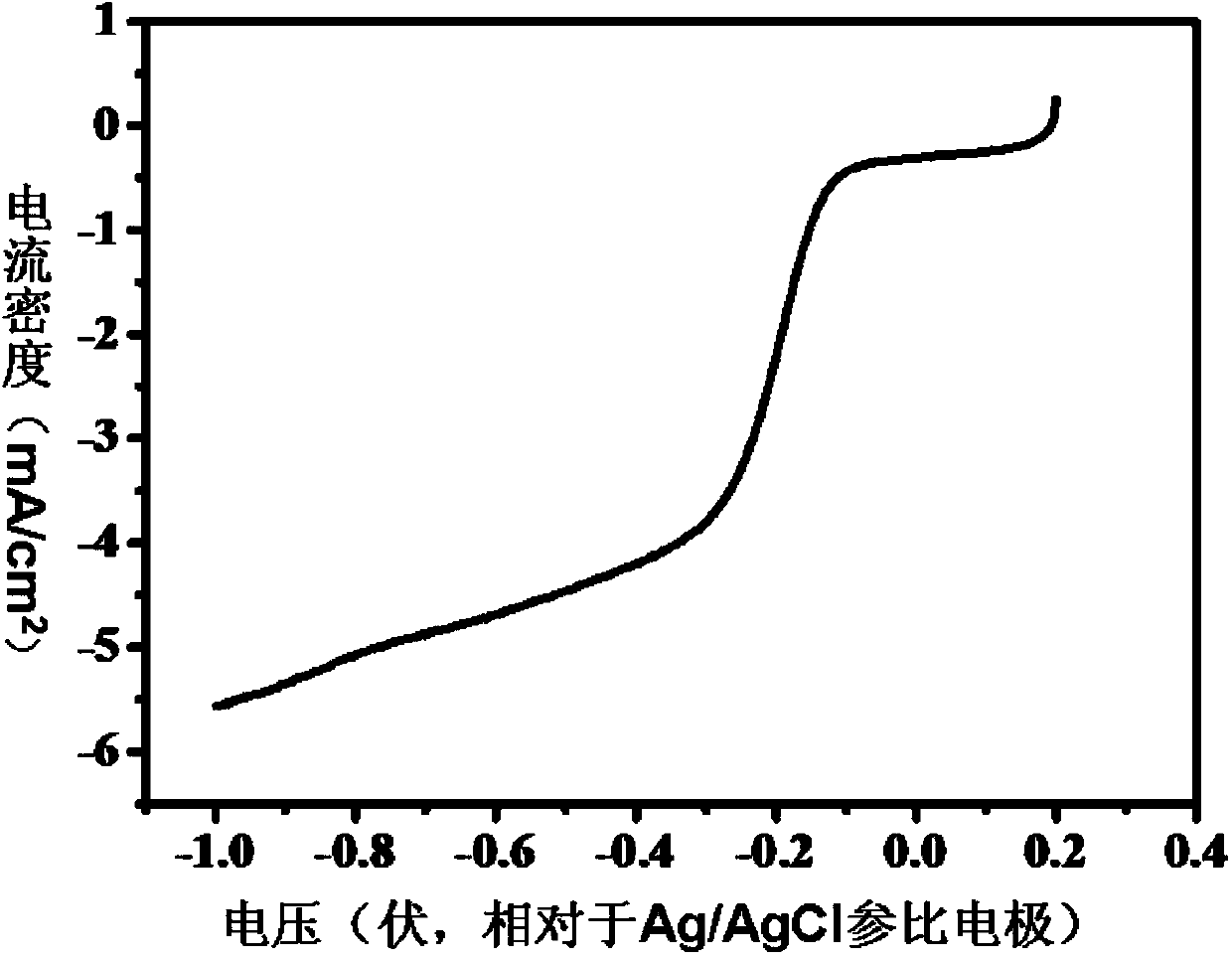

Electrocatalyst for oxygen reduction including silver/silver halide composite, fuel cell including the same, and preparing method of the same

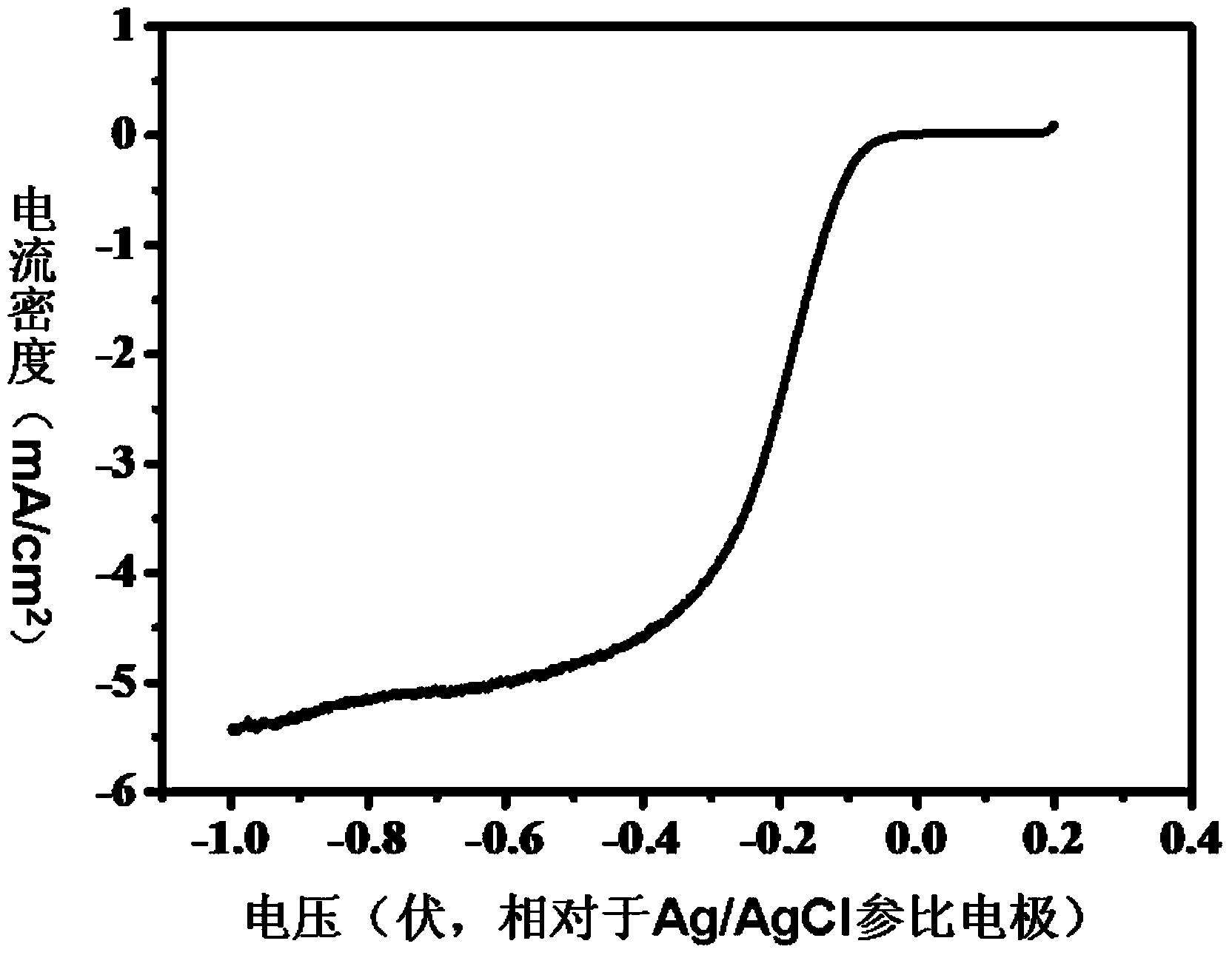

ActiveUS20130273458A1Excellent oxygen reduction catalytic activityImprove stabilityActive material electrodesCatalyst activation/preparationFuel cellsOxygen

The present disclosure relates to an electrocatalyst for oxygen reduction including a silver / silver halide composite, a fuel cell including the electrocatalyst for oxygen reduction, and a method for preparing the electrocatalyst for oxygen reduction.

Owner:EWHA UNIV IND COLLABORATION FOUND

Application of polymer product obtained by polymerizing aromaticnitrile compound as oxygen reduction catalyst

ActiveCN103996861AImprove conductivityRich in nitrogenOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesPolymer scienceOxygen

The invention discloses an application of a polymer product obtained by polymerizing an aromaticnitrile compound as an oxygen reduction catalyst, which belongs to the field of electrochemistry. The polymer product obtained by polymerizing the aromaticnitrile compound is used as the oxygen reduction catalyst, so that the oxygen reduction activity is excellent, the stability is high, the mass preparation can be realized, and the polymer product can be widely applied to the commercial application.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of a nitrogen-doped carbon-oxygen reduction catalyst with a hierarchical porous structure

The invention provides a preparation method for a nitrogen-doped carbon oxygen reduction catalyst with a hierarchical porous structure, belonging to the technical field of a fuel cell. The preparation method comprises the following steps of: firstly, preparing a eutectic molten salt having a three-dimensional macro-porous structure by a freeze drying method; secondly, using the eutectic molten salt as a template, doping a nitrogen-containing precursor, and leading the nitrogen-containing precursor to be oxidized and polymerized on the surface of the eutectic molten salt by a solid-phase polymerization method, wherein ammonium persulfate serves as an oxidizing agent, and a ferric salt serves as a promoter; and finally, carrying out high-temperature pyrolysis and removing the eutectic molten salt. With the adoption of the nitrogen-doped carbon oxygen reduction catalyst with the hierarchical porous structure, the nitrogen-containing precursor can be effectively prevented from pyrolysis loss, structural collapse and sintering during the high-temperature carbonation process, the catalyst yield and the nitrogen doping efficiency are improved, moreover, a large amount of micropores, mesoporous and macropores can be generated, and the mass transfer efficiency of oxygen and water is improved. The method is simple and practical, the production cost is low, and the prepared catalyst has excellent oxygen reduction catalytic activity and can substitute the traditional commercial Pt / C catalyst.

Owner:重庆铈坦新材料技术研究院有限公司

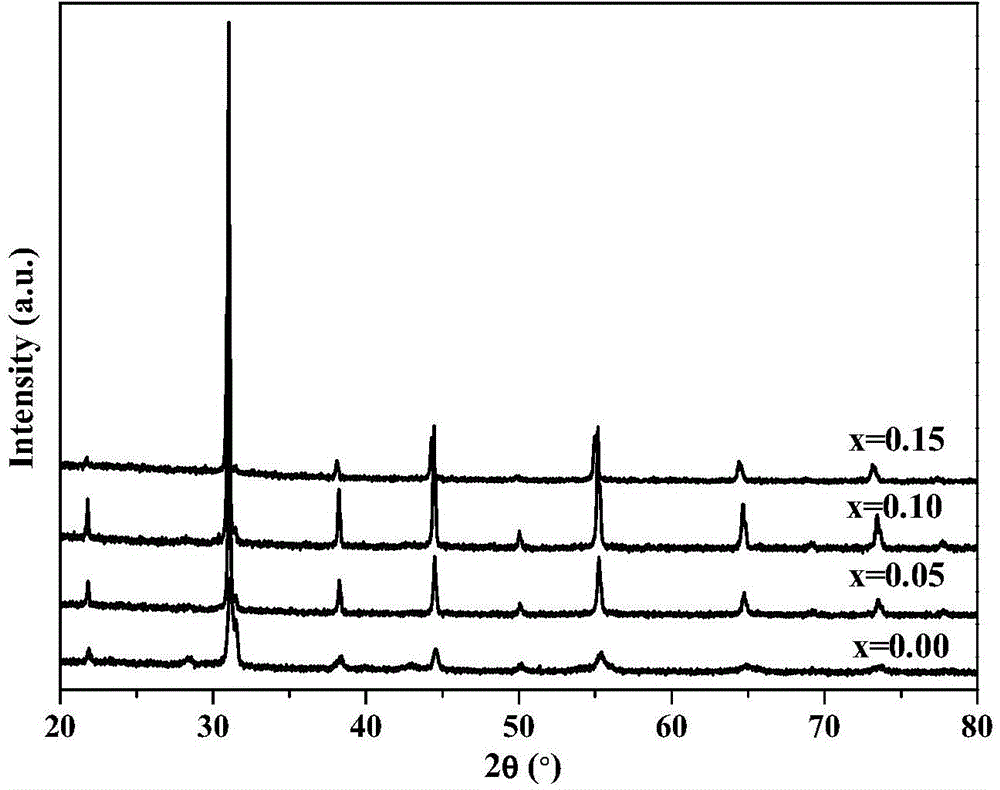

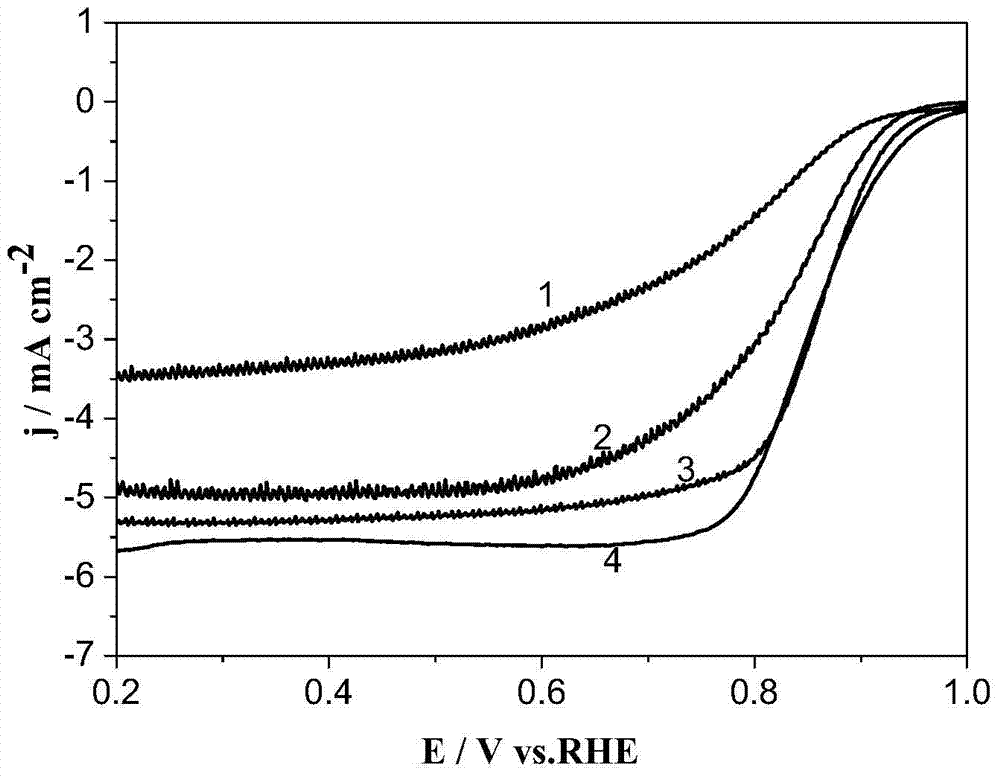

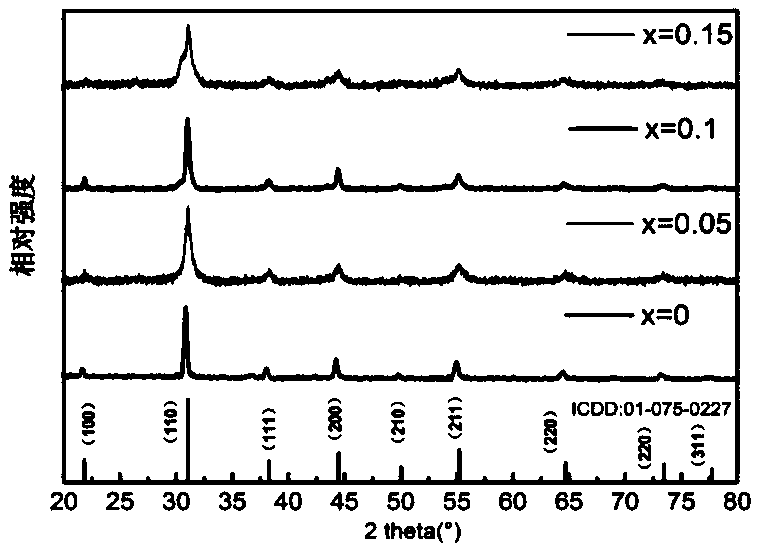

Preparation of cobalt-based cathode material with low thermal expansion coefficient for solid oxide fuel cell and application of cobalt-based cathode material

InactiveCN108666589ASmall coefficient of thermal expansionGood chemical compatibilityCell electrodesFuel cellsFuel cellsExcess oxygen

The invention discloses a cathode material BaNbyZrxCo1-x-yO3-delta with an excellent thermal expansion coefficient for a solid oxide fuel cell. By co-doping Nb2O5 with ZrO2 at Co site of BaCoO3-deltato reduce the thermal expansion coefficient of a BaCoO3-delta base cathode material, a small TEC value (smaller than 15x10<-6>K<-1>) can be obtained and electrochemical properties of the material canbe further improved; a molecular formula is BaNbyZrxCo(1-x-y)O(3-delta), wherein delta represents excess oxygen content or oxygen deficiency content, and is greater than or equal to -1 and smaller than or equal to 1; x represents the doping amount of the ZrO2 and is greater than or equal to 0 and smaller than or equal to 0.5; y represents the doping amount of the Nb2O5 and is greater than or equalto 0 and smaller than or equal to 0.5. The BaNbyZrxCo(1-x-y)O(3-delta) cathode material disclosed by the invention, compared with traditional Co-based materials, has the advantage that the thermal expansion coefficient is greatly reduced; in addition, the BaNbyZrxCo(1-x-y)O(3-delta) cathode material has good chemical compatibility with GDC, good oxygen reduction catalytic activity in the temperature range of 500 to 850 DEG C and suitability for solid oxide fuel cell cathode materials at medium and low temperature.

Owner:HARBIN INST OF TECH

Oxygen reduction catalyst prepared based on tetra-beta-(4-formylphenoxy)phthalocyanine cobalt aerogel and preparation method thereof

ActiveCN110639579ALow costImprove electrocatalytic performanceCatalyst activation/preparationPtru catalystFreeze-drying

The invention relates to the technical field of preparation of catalysts and provides a method for preparing an oxygen reduction catalyst based on tetra-beta-(4-formylphenoxy)phthalocyanine cobalt aerogel. The method comprises the following steps: (1) mixing tetra-beta-(4-formylphenoxy)phthalocyanine cobalt, an organic solvent and an acetic acid-amino enriched organic matter mixed solution, so asto obtain hydrogel; (2) soaking the hydrogel obtained in step (1) into water to remove the surplus solvent; after taking out the hydrogel, soaking the hydrogel into a graphene oxide solution or a multi-walled carbon nanotube solution and adsorbing, so as to obtain compound hydrogel; (3) carrying out freeze drying on the compound hydrogel obtained in step (2), so as to obtain compound aerogel; and(4) carrying out high-heat treatment on the compound aerogel obtained in step (3) under a protection atmosphere, so as to obtain the oxygen reduction catalyst. The invention further provides the oxygen reduction catalyst obtained by the method, and the oxygen reduction catalyst contains N, C and Co at the same time; and raw materials are easy to obtain and the oxygen reduction catalyst is easy toimplement. The product provided by the invention has excellent electrochemical performance and catalytic performance.

Owner:CAPITAL NORMAL UNIVERSITY

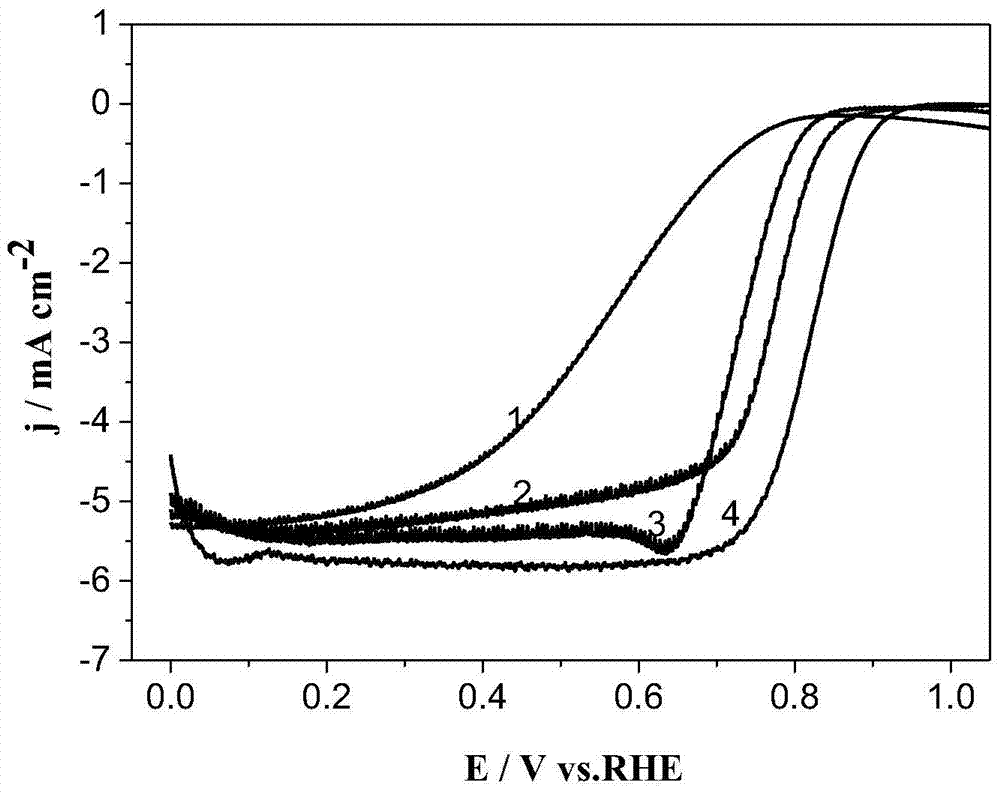

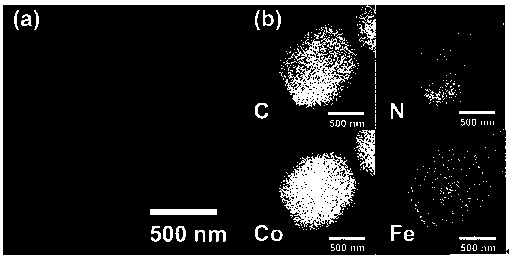

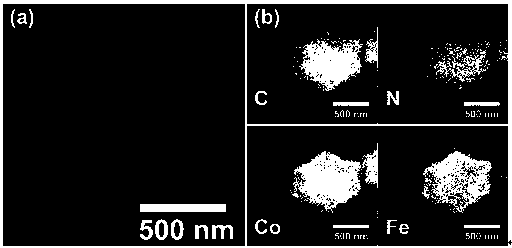

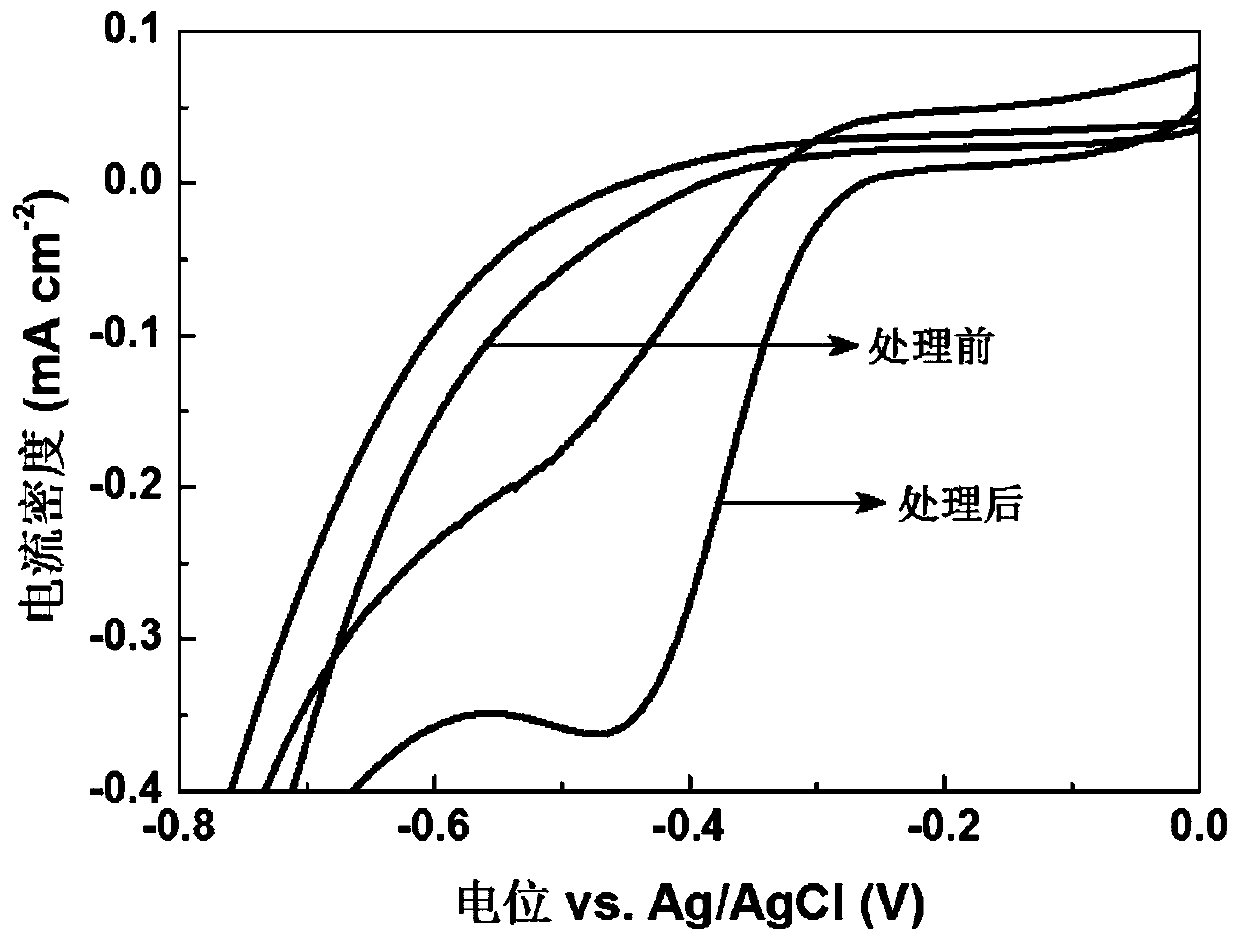

A kind of iron, cobalt, nitrogen co-doped carbon catalyst and its preparation method and application

The invention relates to an iron, cobalt and nitrogen codoped carbon catalyst and a preparation method and application thereof. An iron / cobalt double-metal zeolite imidazate framework material is adopted as a precursor, and the iron, cobalt and nitrogen codoped carbon catalyst is prepared and obtained through high-temperature pyrolysis, wherein the iron / cobalt double-metal zeolite imidazate framework material is prepared by adopting ferrous sulfate, cobalt nitrate and 2-methylimidazole to carry out a self-assembly reaction in a solvent under an oxygen-free environment. The iron, cobalt and nitrogen codoped carbon catalyst prepared in the invention has the advantages that the oxygen reduction catalytic activity, electrochemical stability and methanol poisoning resistance is superior to those of commercial Pt / C, the cost is low, the preparation method is simple and volume production can be realized. The catalyst disclosed by the invention can be widely applied to the fields of fuel batteries, metal-air batteries and the like.

Owner:BEIJING UNIV OF CHEM TECH

A kind of method of diamond film surface graphitization

InactiveCN108707874BIncrease energy densityEasy to changeCell electrodesChemical vapor deposition coatingBeam energySurface oxidation

The invention belongs to the technical field of catalytic material preparation and provides a diamond film surface graphitizing method. A high current pulsed electron beam is used for bombarding the diamond surface, the micro-area bombarded by the high current pulsed electron beam can meet the thermodynamic and kinetic conditions for a diamond to be changed into graphite under the high-temperatureand low-pressure environment, and graphitizing only occurs on the diamond surface. The diamond film surface graphitizing method specifically comprises the steps that after a washed substrate with a surface oxidation layer being removed is arranged in diamond powder suspension liquid to be subjected to ultrasonic treatment, the substrate is put on a sample platform in hot filament chemical vapor deposition equipment to be subjected to fine purification and activating treatment; and a base material with a deposited diamond film is fixed to a clamping device in a high current pulsed electron beam device to be treated, and then a surface graphitized diamond film is obtained. According to the diamond film surface graphitizing method, the high current pulsed electron beam energy density is high, the high-temperature and low-pressure conditions of the micro-area are more beneficial to graphitizing conversion of the diamond, and a cathode catalyst with a good heat conductivity, conductivity and oxygen reduction catalytic activity is formed.

Owner:DALIAN UNIV OF TECH

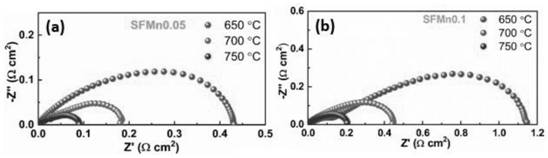

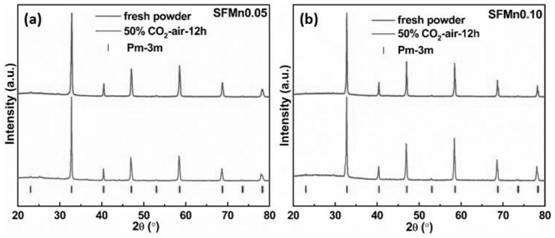

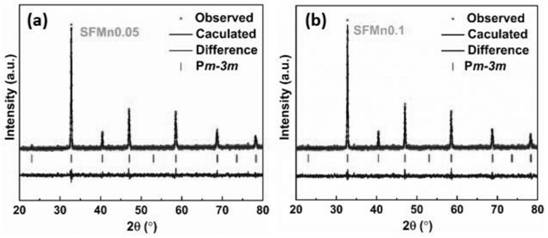

Anticarbon dioxide solid oxide fuel cell cathode material and preparation method thereof

PendingCN113809343AImprove stabilityOvercoming the disadvantage of severe attenuationCell electrodesFuel cellsMaterials science

The invention provides a solid oxide fuel cell cathode material. The chemical formula of the cathode material is SrFe1-xMnxO3-delta, and x is not less than 0.05 and not more than 0.5. According to the cathode material disclosed by the invention, the SrFeO3-delta material is converted from a tetragonal phase to a cubic phase at room temperature by doping low-valence elements at a B site, has good oxygen reduction catalytic activity, shows excellent anti-carbon dioxide stability, and overcomes the defect that a common cathode is severely attenuated in a carbon dioxide-containing atmosphere; and the cathode material is an excellent carbon dioxide-resistant cathode material for the solid oxide fuel cell.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing boron carbon nitride nanotube with high oxygen reduction catalytic activity

ActiveCN102950015BAvoid high temperature (>1000°C) conditionsMild reaction conditionsPhysical/chemical process catalystsCell electrodesNitrogen gasVacuum drying

The invention discloses a method for preparing a boron carbon nitride nanotube with high oxygen reduction catalytic activity. The method mainly comprises the following steps of: sequentially adding 6-18 weight percent of analytically pure NaN3, 6-21 weight percent of analytically pure NH4BF4, 1-10 weight percent of analytically pure surfactant and 8-25 weight percent of analytically pure purely anhydrous acetonitrile into benzene under nitrogen protection, and stirring for 15 to 30 minutes; adding the mixture into a stainless steel reaction kettle for sealing, putting the reaction kettle in a crucible furnace, heating at the temperature of 300-600 DEG C for 8-36 hours, naturally cooling the reaction kettle to room temperature, and taking out the mixture; and sequentially washing the mixture for 3-5 times by using absolute ethyl alcohol, diluted hydrochloric acid and distilled water, filtering, and performing vacuum drying on the powder in a vacuum drying box at the temperature of 60-100 DEG C for 6-10 hours. The method is simple in process, moderate in reaction conditions and low in cost, a metal catalyst is not required, the prepared boron carbon nitride nanotube has excellent oxygen reduction catalytic activity, and large-scale production can be realized.

Owner:YANSHAN UNIV

Porous graphene and graphene quantum dots and preparation method thereof

ActiveCN104555999BUniform pore size distributionExcellent oxygen reduction catalytic activityGraphenePorous grapheneGraphite

The invention discloses porous graphene and a graphene quantum dot. The porous graphene comprises, but is not limited to 2-9 atomic layers, wherein each atomic layer simultaneously comprises crystal lattices and holes of graphene, but is not limited to the holes of which the apertures are 2-10nm; the area of the holes accounts for about 5%-40% of total area of each atomic layer. The graphene quantum dot is characterized by comprising 1-5 atomic layers; the boundary is in a sawtooth shape; and the dimension of the quantum dot is 2-10nm. The porous graphene disclosed by the invention is uniform in aperture distribution, and not equal in interlayer spacing; and the graphene quantum dot has the advantages of high luminous efficacy, good crystal form and few defects.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

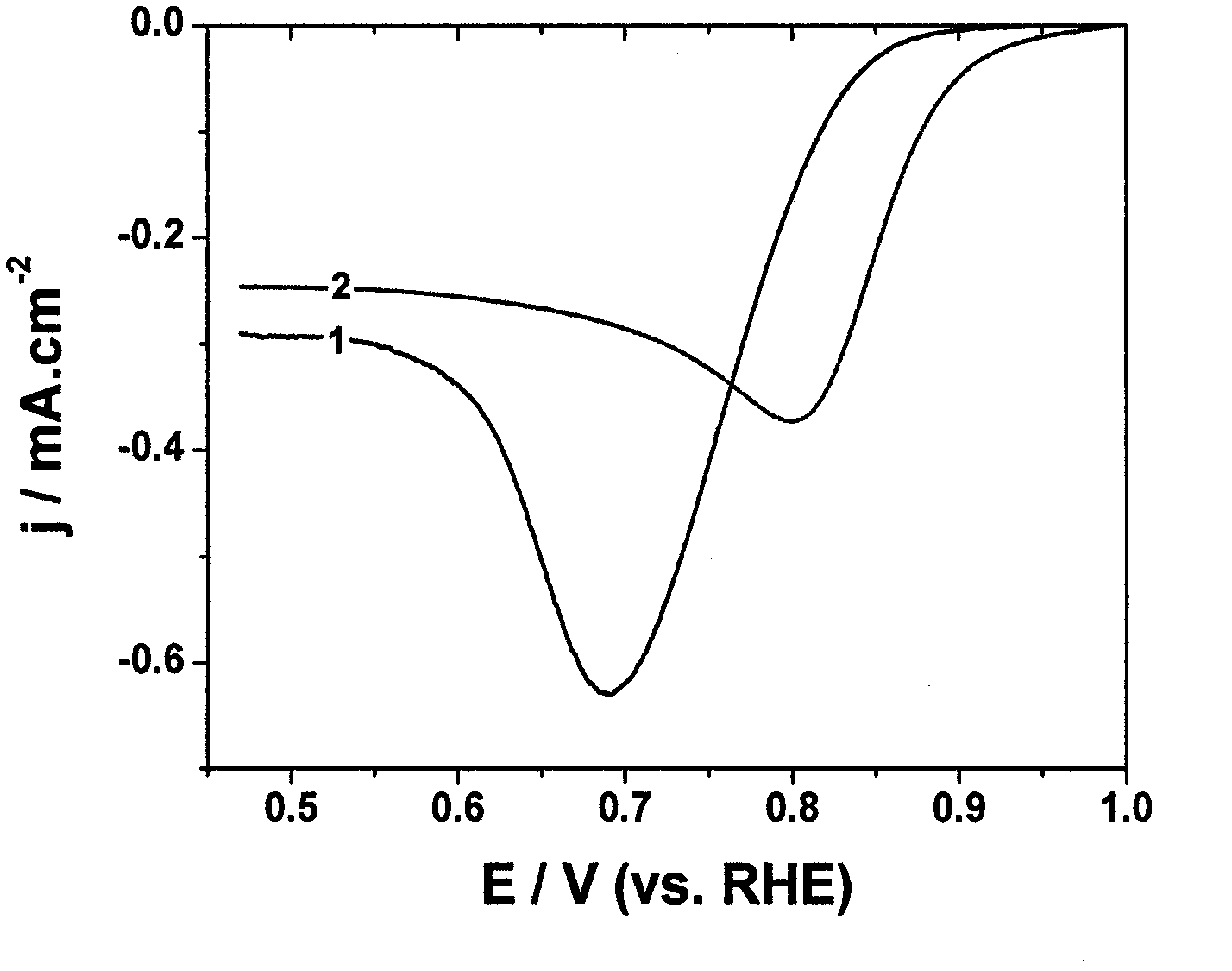

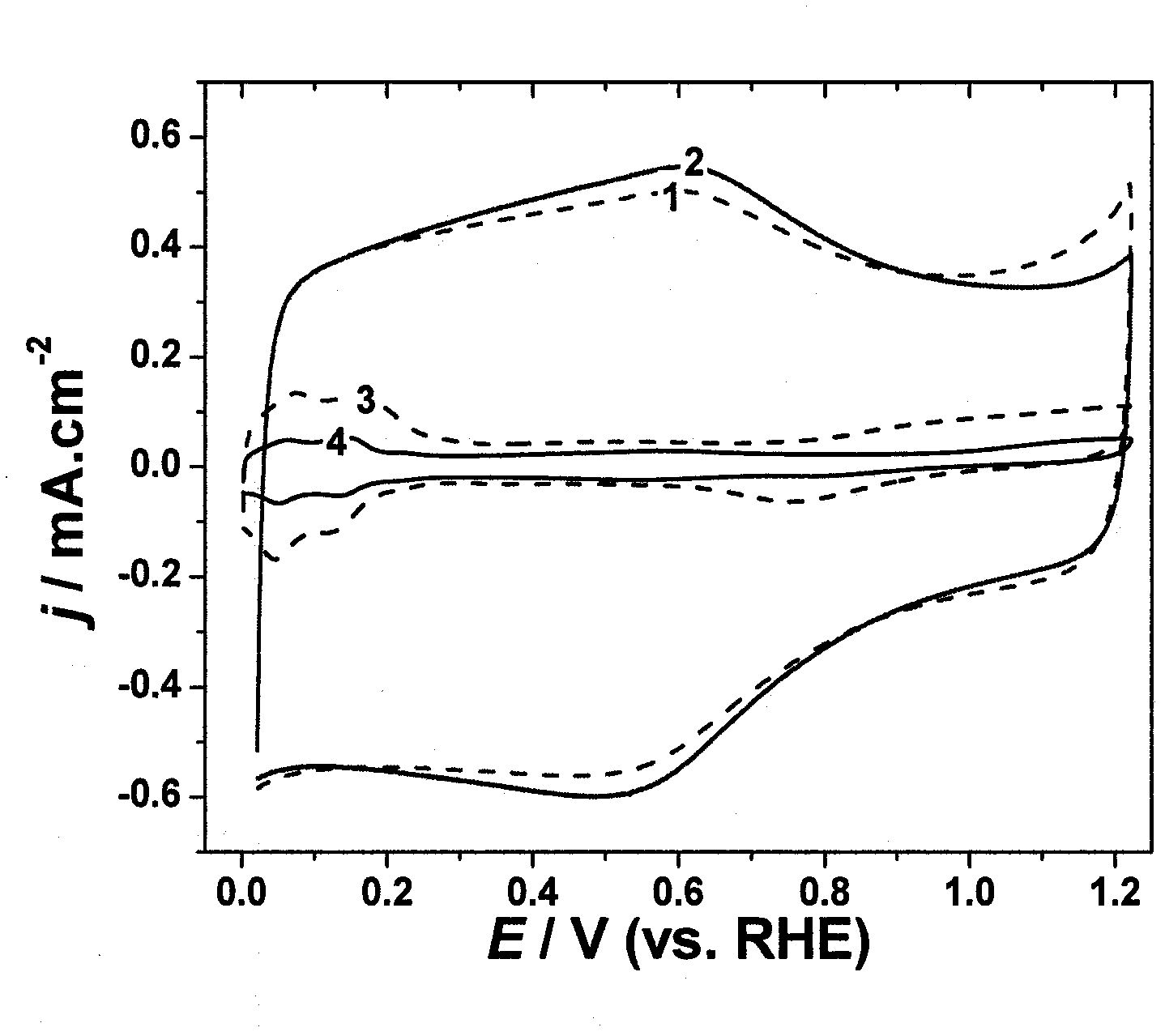

A PD-based passivation film with high catalytic activity and preparation method thereof

The invention discloses a Pd-based passivation film with high catalytic activity and a preparation method thereof. The passivation film contains the following components by atomic percentage: 80-90% of Pd, 10-20% of Ni; the passivation film also contains It includes one of Mo or Nb, and contains the following components by atomic percentage: 80-90% of Pd, 8-18% of Ni, and the rest is Mo or Nb, and not more than 2%. The preparation steps are as follows: 1) Polish PdNi homogeneous solid solution, PdNiMo homogeneous solid solution or PdNiNb homogeneous solid solution within a certain pressure range to make the surface smooth and inject residual stress to obtain a polished sample; 2) Polish the polished sample in Perform constant-voltage electrochemical corrosion in corrosion solution I to obtain a passivation film; 3) place the passivation film in corrosion solution II and scan it by cyclic voltammetry, then remove and wash it. The invention solves the problems of poor catalytic stability of existing fuel cells and the like.

Owner:SOUTHEAST UNIV

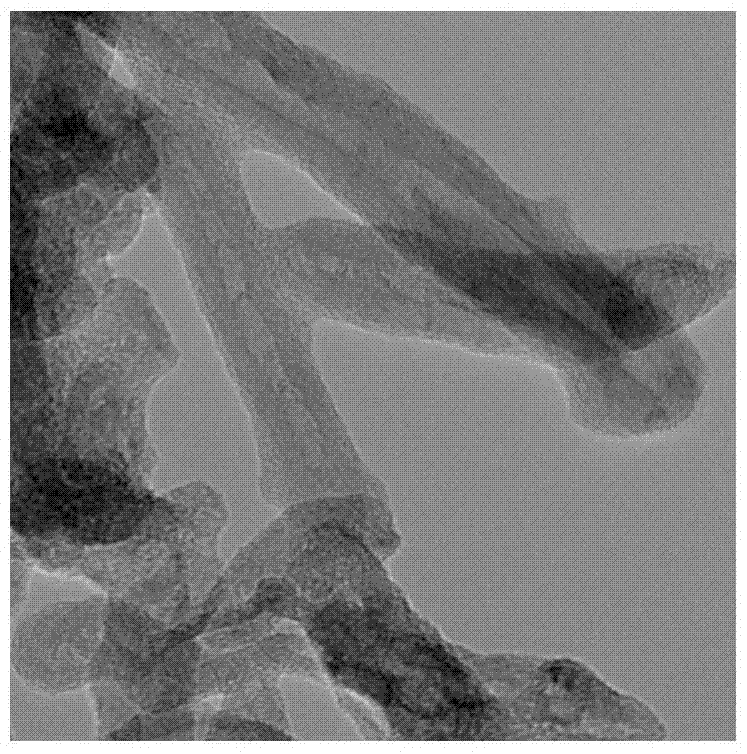

A nitrogen-containing amorphous carbon layer-wrapped carbon nanotube one-dimensional material with a core-shell structure and its preparation method and application

InactiveCN104707638BThe synthesis method is simpleMild conditionsMaterial nanotechnologyPhysical/chemical process catalystsCarbon layerModified carbon

The invention relates to a nitrogen-containing amorphous carbon layer-wrapped carbon nanotube oxygen reduction catalyst with a core-shell structure. The specific preparation steps are as follows: at room temperature, appropriate amounts of terephthalaldehyde and tetrakis(4-carboxyphenyl)porphyrin are respectively dissolved in ethanol solution, and then a certain amount of acetic acid solution is added to the two solutions respectively. Then ultrasonically disperse the amino-modified carbon nanotubes in the terephthalaldehyde solution and keep ultrasonicating for a period of time. Next, the carbon nanotubes are separated by centrifugation, and then these carbon nanotubes are ultrasonically dispersed in a tetrakis (4-aminophenyl) porphyrin solution, and the ultrasonic wave is also continued for a certain period of time before centrifugation. After repeating this process twice, the carbon nanotubes were taken out and dried. Finally, the obtained material is treated at 600-900 degrees Celsius for two hours under nitrogen or vacuum atmosphere to obtain the product. The method has the advantages of simple process, low equipment requirement, low energy consumption, and simple and easy-to-control reaction process; the obtained material exhibits good oxygen reduction reaction activity in an alkaline environment.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application

ActiveCN112038648BRich reservesThe preparation process is simple and controllableCell electrodesNanotechnologyPtru catalystMicrosphere

The invention relates to a transition metal cobalt and nitrogen co-doped carbon-oxygen reduction catalyst with a hollow structure, and a preparation method and application thereof. Ethylene microspheres are used as templates, and the zeolite imidazolate metal organic framework material is grown on the surface of the template by the electrostatic interaction between the sulfonic acid groups on the surface of the microspheres and the metal cobalt ions, and then prepared by pyrolysis carbonization in an inert atmosphere. The method provided by the invention can effectively improve the active site utilization rate of the transition metal cobalt and nitrogen co-doped carbon catalyst, the prepared catalyst can efficiently catalyze the oxygen reduction reaction of the fuel cell cathode, and the oxygen reduction catalytic activity is better than that of commercial Pt / C.

Owner:BEIJING UNIV OF CHEM TECH

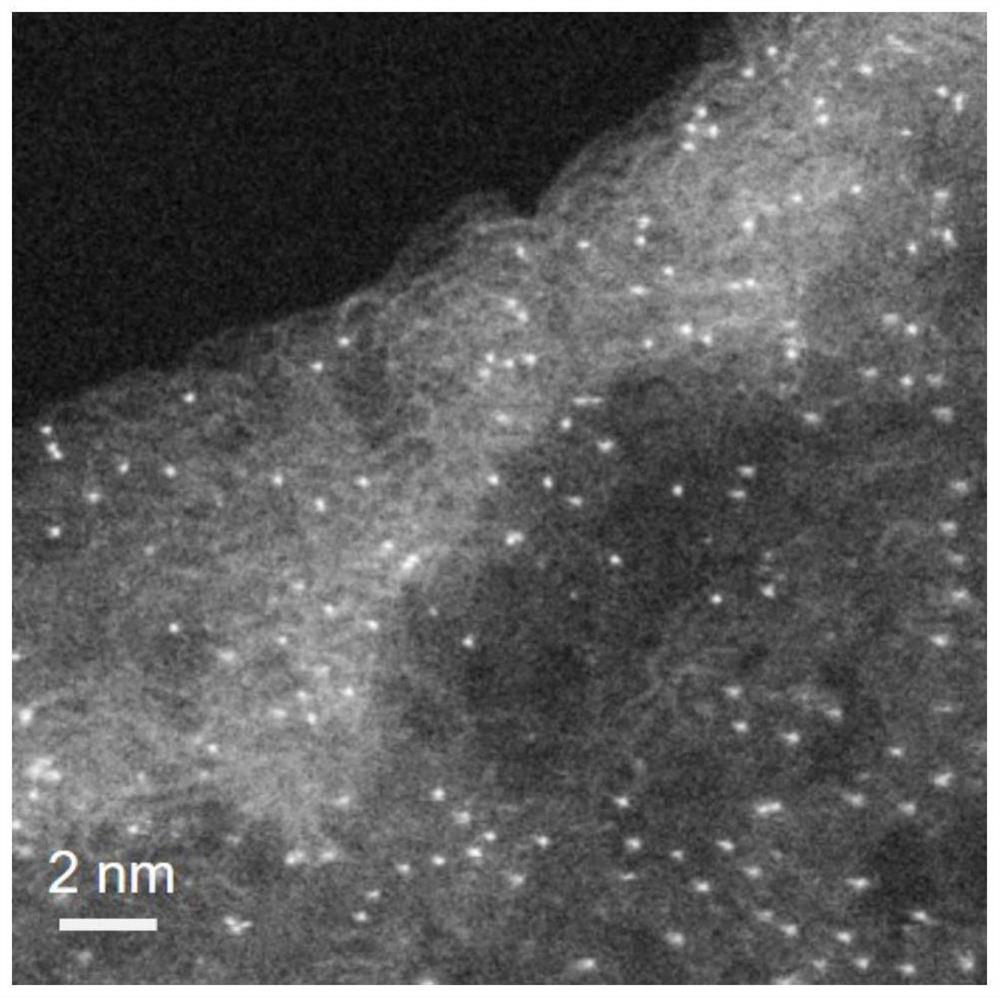

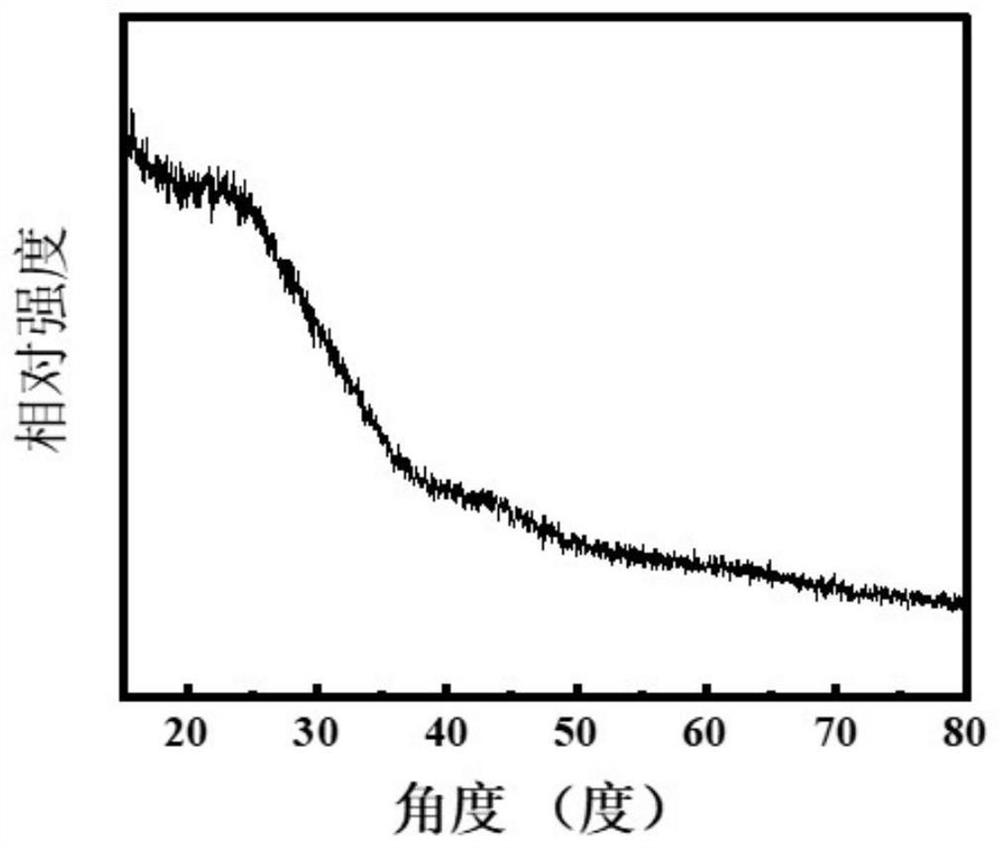

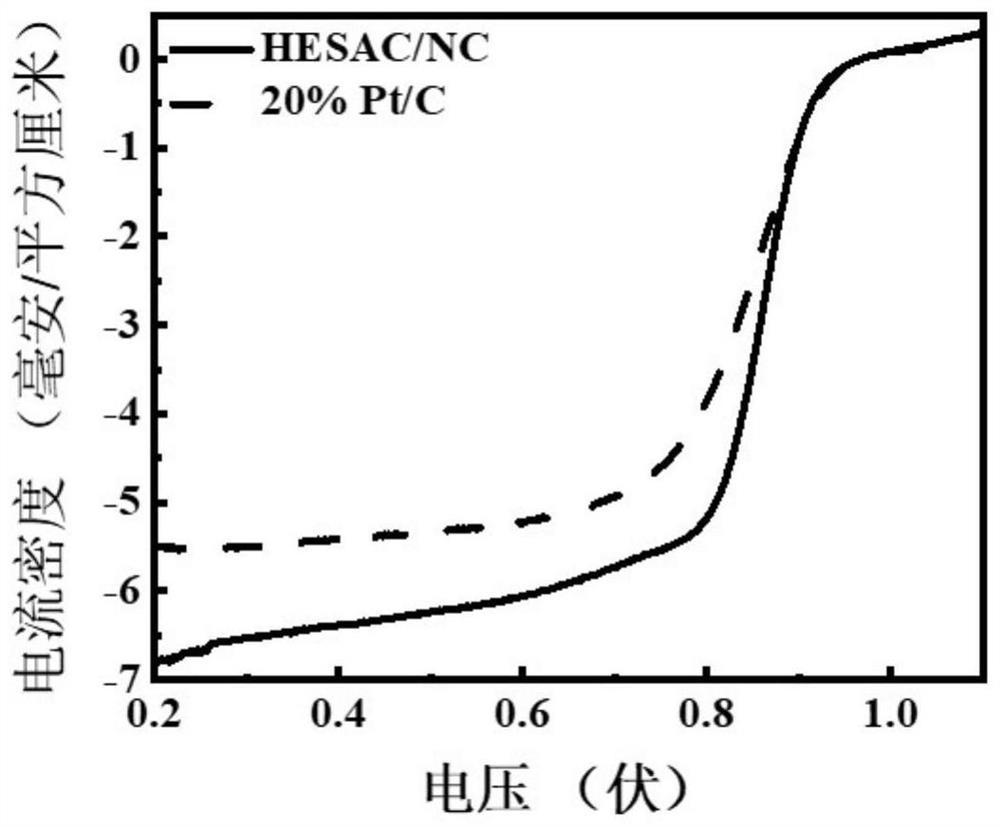

High-entropy monatomic catalyst and preparation method thereof

PendingCN114534742AAchieving controllable preparationExcellent oxygen reduction catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystDistillation

The invention discloses a high-entropy monatomic catalyst and a preparation method thereof. A specific embodiment of the preparation method of the high-entropy monatomic catalyst comprises the following steps: preparation of a mixed metal precursor: dissolving a carbon template precursor and a plurality of metal precursors in an acid solution to obtain a first mixed solution; the first mixed solution is evaporated to dryness in a reduced pressure distillation mode and then roasted in a muffle furnace, and a mixed metal precursor is obtained; preparation of a high-entropy monatomic catalyst: dissolving a mixed metal precursor and a carbon-coated precursor in a buffer solution to obtain a second mixed solution; and carrying out suction filtration on the second mixed solution, drying, and roasting in a tubular furnace to obtain the high-entropy monatomic catalyst. Therefore, five or more metal components can be uniformly loaded in the graphene-like carbon material in a monatomic form to form the high-entropy monatomic catalyst, so that the oxygen reduction catalytic activity of the high-entropy monatomic catalyst is improved.

Owner:HAINAN UNIVERSITY +2

Pd-based passivation film with high catalytic activity and preparation method thereof

The invention discloses a Pd-based passivation film with high catalytic activity and a preparation method thereof. A passivation film contains following components 80-90% of Pd and 10-20% of Ni by atomic percentage, the passivation film further includes one of Mo or Nb and contains following components 80-90% of Pd and 8-18% of Ni by atomic percentage, and the balance is Mo or Nb and not more than2%. The method comprises steps, 1), PdNi homogeneous solid solution, PdNiMo homogeneous solid solution or PdNiNb uniform solid solution are polished in a certain pressure range, the surface is made to be smooth, residual stress is injected, and polished sample is obtained; 2), the polished sample is subjected to constant pressure electrochemical etching in etching solution I to obtain a passivation film; and 3), the passivation film is placed in etching solution II and scanned by cyclic voltammetry, after that, the product is picked out and cleaned to obtain the Pd-based passivation film. Themethod is advantaged in that a problem of poor catalysis stability of a fuel cell in the prior art is solved.

Owner:SOUTHEAST UNIV

An oxygen reduction catalyst prepared based on tetra-β-(4-formylphenoxy)cobalt phthalocyanine airgel and its preparation method

ActiveCN110639579BLow costImprove electrocatalytic performanceCatalyst activation/preparationAcetic acidPtru catalyst

The invention relates to the technical field of catalyst preparation, and provides a method for preparing an oxygen reduction catalyst based on tetra-β-(4-formylphenoxy)cobalt phthalocyanine airgel: (1) combining tetra-β-(4- Aldehydephenoxy) cobalt phthalocyanine, organic solvent and acetic acid-amino-rich organic mixture are mixed to obtain a hydrogel; (2) immerse the hydrogel obtained in step (1) in water to remove excess solvent, and take out the hydrogel Immerse in graphene oxide solution or multi-walled carbon nanotube solution again and carry out adsorption, obtain composite hydrogel; (3) carry out freeze-drying to the composite hydrogel obtained in step (2), obtain composite aerogel; (4 ) Under a protective atmosphere, the composite airgel obtained in step (3) is subjected to high heat treatment to obtain an oxygen reduction catalyst. The invention also provides the oxygen reduction catalyst obtained by the method, which contains N, C and Co at the same time, and the raw materials are easy to obtain and easy to implement. The product of the invention has excellent electrochemical performance and catalytic performance.

Owner:CAPITAL NORMAL UNIVERSITY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com