Soybean biological base fuel cell oxygen reduction catalyst and preparation method and application thereof

A fuel cell, bio-based technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as hindering the development of fuel cells and high cost of Pt, and achieve the effects of saving raw materials, improving yield, and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

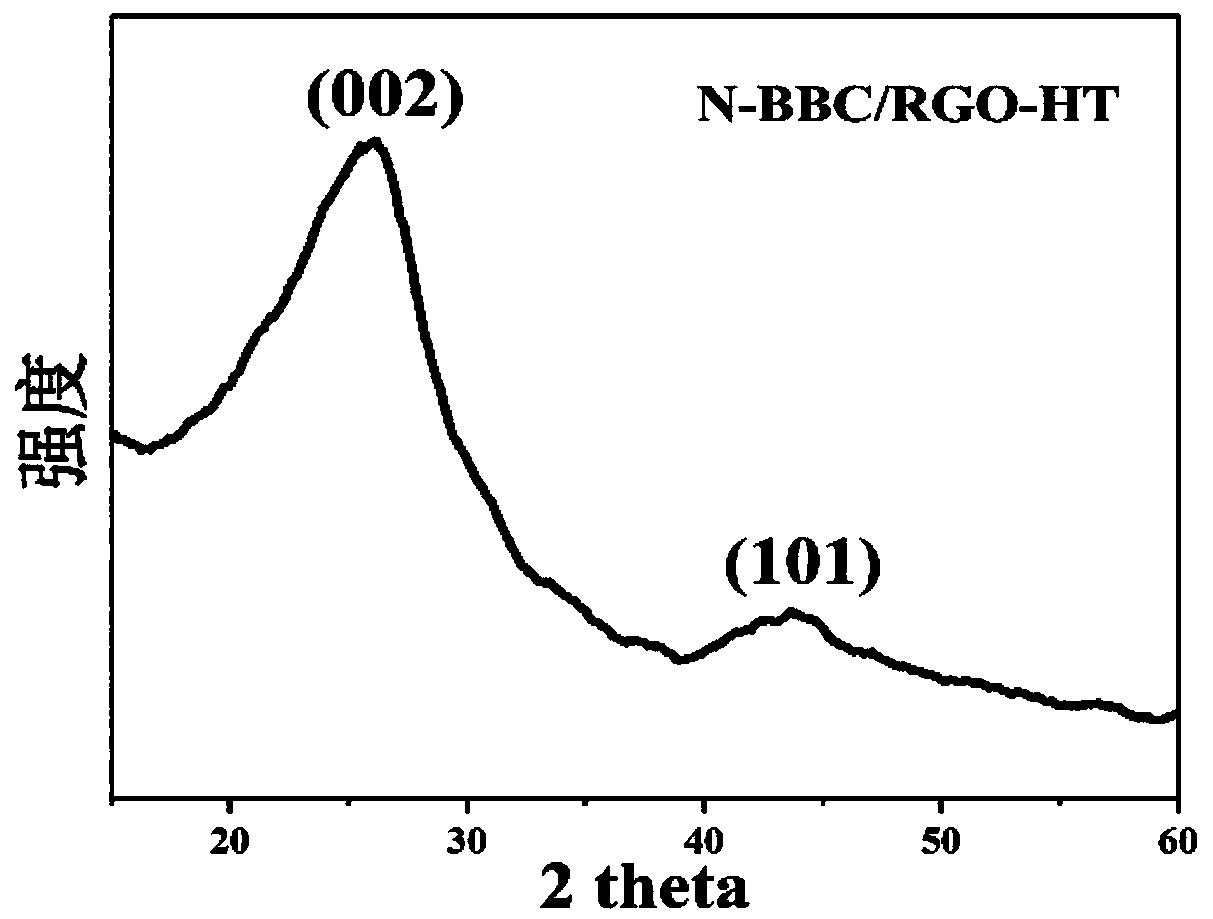

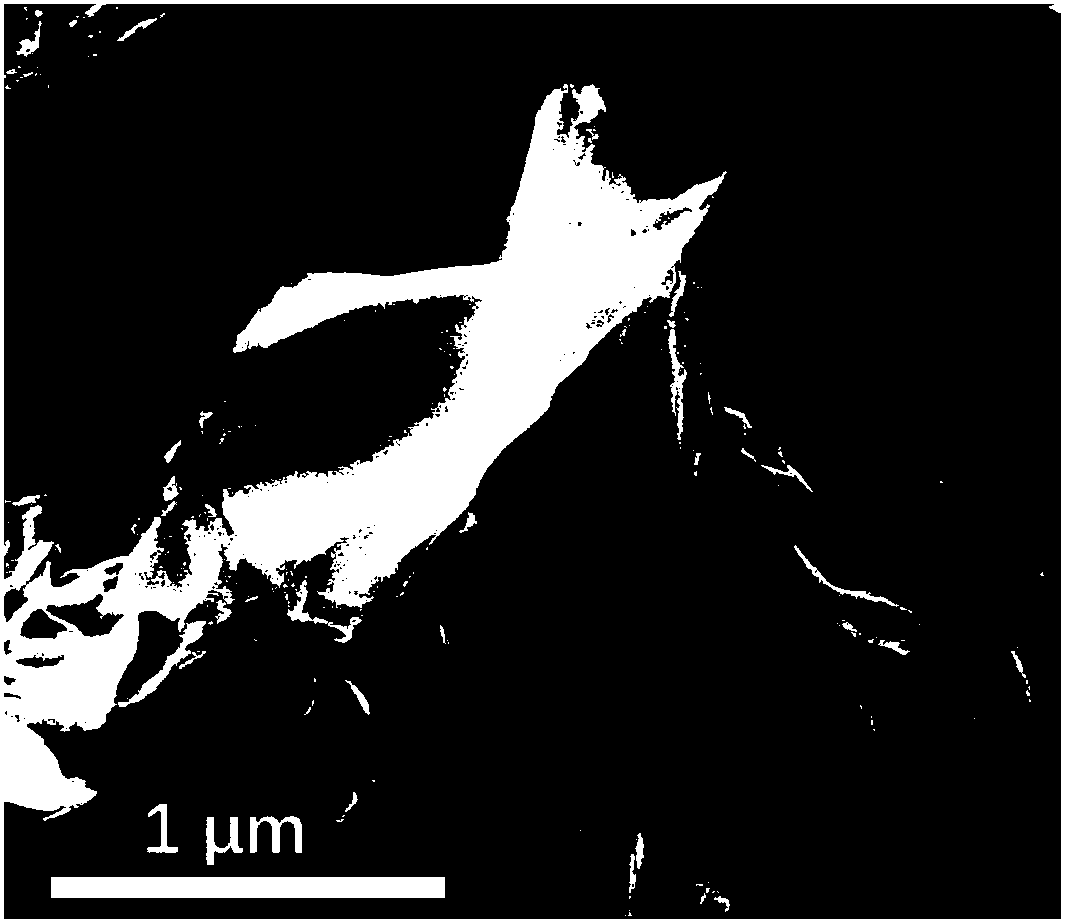

[0039] The preparation of graphene oxide of the present invention is improved on the basis of the Hummers method; what the raw material of existing Hummers method prepares graphene oxide adopts four kinds of graphite powder, potassium nitrate, potassium permanganate and concentrated sulfuric acid, and the reaction time is as long as 24h, the graphene loss after preparation is serious, for example preparation 3g graphene can only obtain 2g graphene oxide product; And the raw material that the improved Hummers method of the present invention adopts is graphite powder, potassium permanganate and the vitriol oil, has saved Potassium nitrate is oxidized by the strong oxidizing ability of potassium permanganate and concentrated sulfuric acid. Through the ratio developed and designed by the laboratory, the reaction only takes 12 hours, which saves raw materials and shortens the reaction time. The preparation of 3g graphene can 2.5-2.6 g of graphene oxide is obtained, and the yield is ...

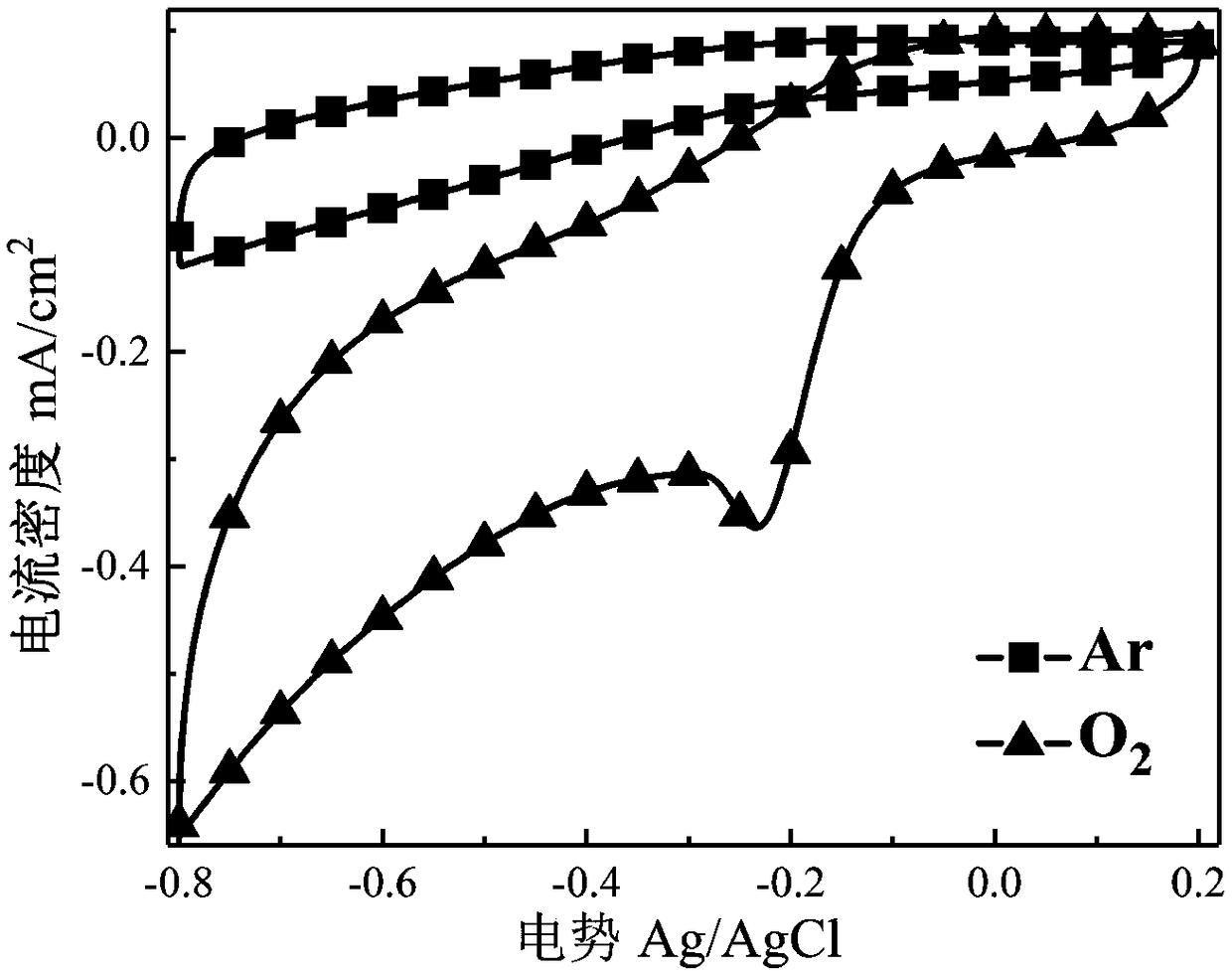

Embodiment 1

[0050] Graphene is to utilize natural graphite powder to adopt improved Hummers method to prepare, and the steps are as follows: Weigh 3g graphite powder, 114g concentrated sulfuric acid and slowly add in dry 500mL beaker, under stirring, slowly add 15g potassium permanganate, then react for 12h ; Slowly pour the viscous dark green reactant into 200mL of pure water, and add 15mL of 30% hydrogen peroxide solution dropwise. At this time, the color of the solution turns bright yellow and bubbles come out, and then use deionized water successively. 3% dilute sulfuric acid and ethanol were centrifuged and washed three times each; the precipitate was collected and purified water was added to 500mL to prepare a 3g / 500mL graphene oxide dispersion for later use.

[0051] The preparation of soybean bio-based fuel cell oxygen reduction catalyst, that is, nitrogen-doped carbon biomass-derived carbon-based catalyst, the steps are as follows: soybeans are ground in a soymilk machine to form ...

Embodiment 2

[0058] Graphene is to utilize natural graphite powder to adopt improved Hummers method to prepare, and the steps are as follows: Weigh 3g graphite powder, 114g concentrated sulfuric acid and slowly add in dry 500mL beaker, under stirring, slowly add 15g potassium permanganate, then react for 12h ; Slowly pour the viscous dark green reactant into 200mL of pure water, and add 15mL of 30% hydrogen peroxide solution dropwise. At this time, the color of the solution turns bright yellow and bubbles come out, and then use deionized water successively. 3% dilute sulfuric acid and ethanol were centrifuged and washed three times each; the precipitate was collected and purified water was added to 500mL to prepare a 3g / 500mL graphene oxide dispersion for later use.

[0059] The preparation of oxygen reduction catalyst for soybean bio-based fuel cell, that is, nitrogen-doped carbon biomass-derived carbon-based catalyst, the steps are as follows: 70g of soybean is ground in a soymilk machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com