BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, preparation method and applications thereof

A fuel cell cathode and solid oxide technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as difficult structure stability, and achieve improved structural stability, good oxygen reduction catalytic activity, enhanced electrical conductivity and oxygen reduction The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a perovskite-type cathode material used in a medium-low temperature solid oxide fuel cell, and its chemical formula is BaBi x NbyCo 1-x-y o 3-δ , where δ represents oxygen excess or deficiency, -1≤δ≤1; x represents Bi 2 o 3 Doping amount, 0≤x≤0.15; y means Nb 2 o 5 The amount of doping, 0≤y≤0.2.

[0040] The cathode material used by the solid oxide fuel cell represented by the above chemical formula is B-site Bi 2 o 3 and Nb 2 o 5 Co-doped BaBi with perovskite crystal structure x Nb y co 1-x -y o 3-δ , by Bi 2 o 3 and Nb 2 o 5 Co-doping can improve the electrochemical performance in order to prepare SOFC cathode materials with stable structure and good chemical compatibility.

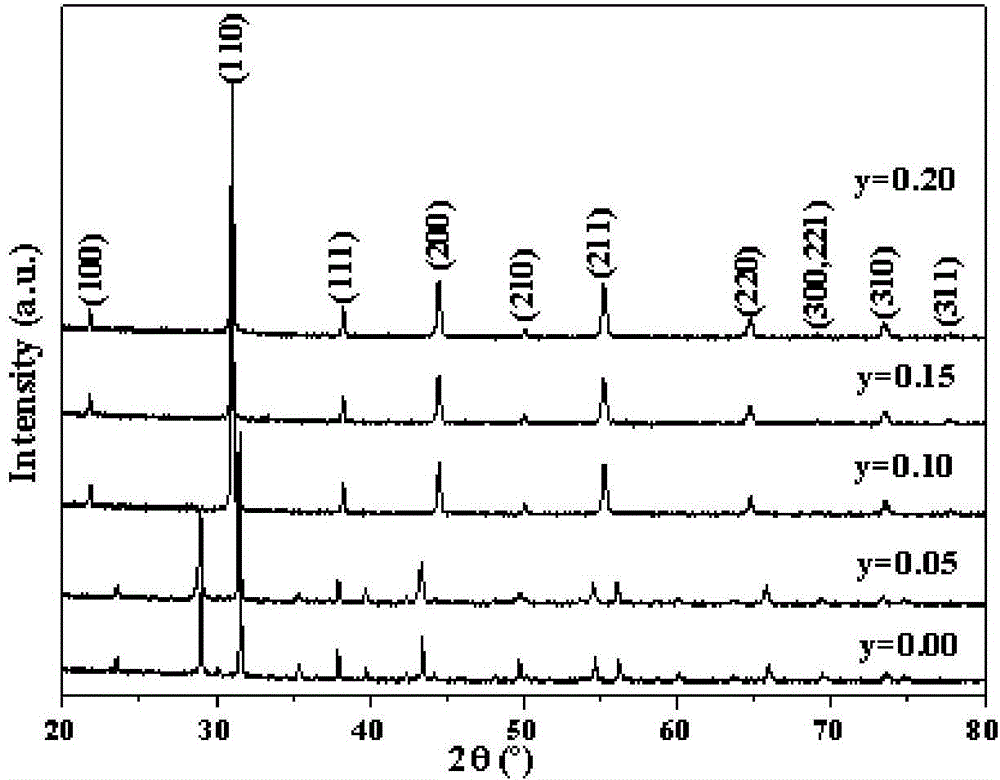

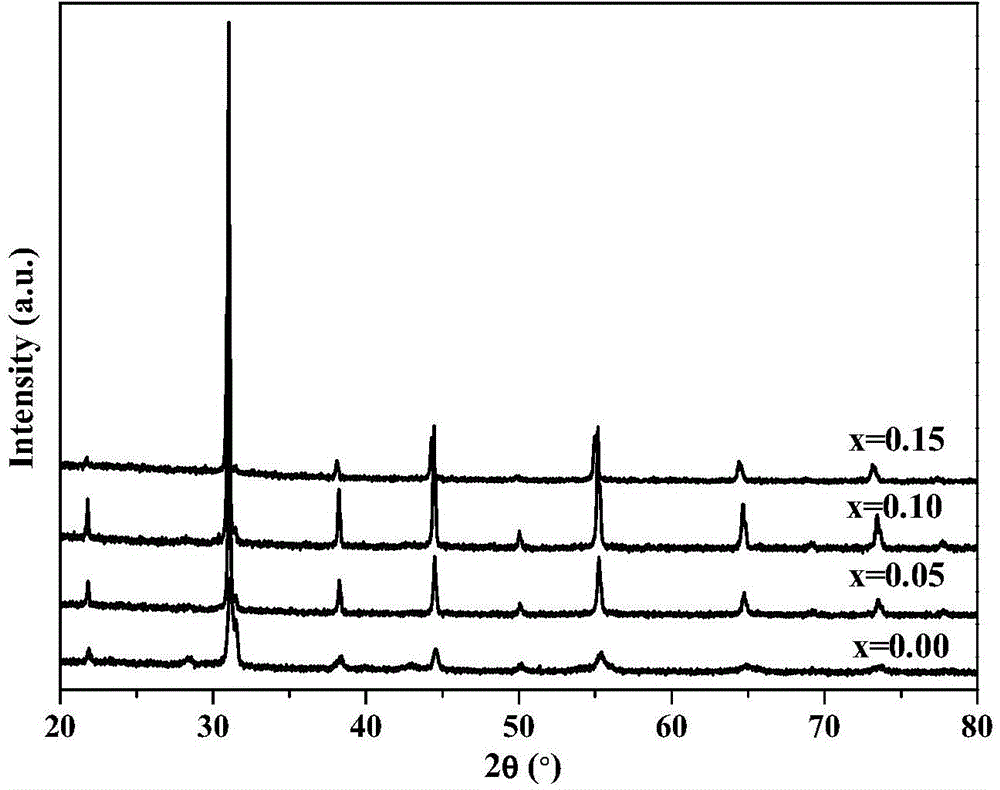

[0041] Depend on figure 2 It can be seen that when x=0.05, y=0, 0.05, 0.10, 0.15 or 0.20, BaBi 0.05 Nb y co 0.95-y o 3-δ It is indeed a perovskite structure; image 3 It can be seen that when y=0.10, x=0.05, 0.10 and 0.15, BaBi x Nb 0.1 co 0.9-...

Embodiment 2

[0043] This embodiment provides a low temperature solid oxide fuel cell cathode material BaBi in Embodiment 1 0.05 Nb y co 0.95-y o 3-δ The preparation and characterization method specifically include the following steps:

[0044] Step 1: Using metal oxides or carbonates as raw materials, weighing according to the stoichiometric formula, using anhydrous ethanol dispersant as the medium, and using a high-energy ball mill to mill for 12 hours;

[0045] Step 2: Initially calcine the precursor after ball milling at 900°C for 10 hours;

[0046] Step 3: After grinding the powder obtained by initial firing, final firing at 1100°C for 5 hours to obtain cathode powder;

[0047] Step 4: Add ethyl cellulose which accounts for 0.5-3% of the mass of the cathode powder, dry press it in a steel casting mold at 10-30 MPa for 5-15 minutes, and raise the temperature of the pressed sample to 900-900 °C in a high-temperature furnace Calcining at 1100° C. for 1 to 3 hours to prepare a dense s...

Embodiment 3

[0050] This embodiment provides a BaBi 0.05 Nb 0.15 co 0.8 o 3-δ The scheme of preparation and performance characterization, specifically includes the following experimental steps:

[0051] Step 1: Weigh 3.947 grams of analytically pure barium carbonate, 1.284 grams of tricobalt tetroxide, 0.399 grams of niobium pentoxide and 0.233 grams of bismuth trioxide, use 20 mL of absolute ethanol as a dispersant, and use a high-energy ball mill at a speed of 300 rpm Ball milling for 12h.

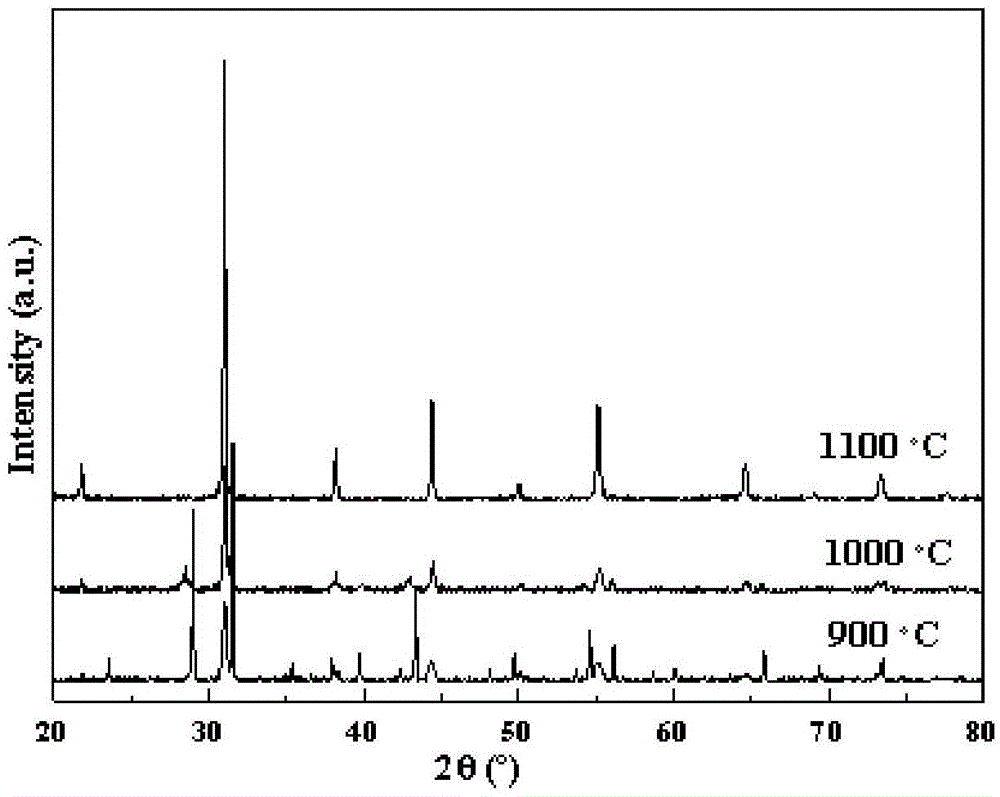

[0052] Step 2: drying the precursor after ball milling, and initial firing at 900-1100° C. for 10 hours in an air atmosphere, and then cooling down to room temperature. The XRD spectrum of the prepared powder is shown in figure 1 , indicating that the prepared cathode powder can indeed obtain a perovskite structure.

[0053] Step 3: The powder obtained by initial firing is ground and then finally fired at 1100°C for 5 hours to obtain the desired cobalt-based perovskite-type cathode powder BaBi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com