Preparation method of nitrogen-doped carbon nanofiber loaded gold nanoparticle oxygen reduction catalyst

A technology of gold nanoparticles and nanofibers, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high price, low platinum reserves, poor stability, etc., and achieve low cost and preparation The method is simple and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Concrete preparation steps are as follows:

[0030] 1) Soak the bacterial cellulose with deionized water until neutral, drain the water, add dopamine solution and stir in a constant temperature water bath at 50°C, then add a Tri-HCl buffer solution with pH=8.5 and continue stirring, and finally obtain bacterial cellulose and Complex of polydopamine.

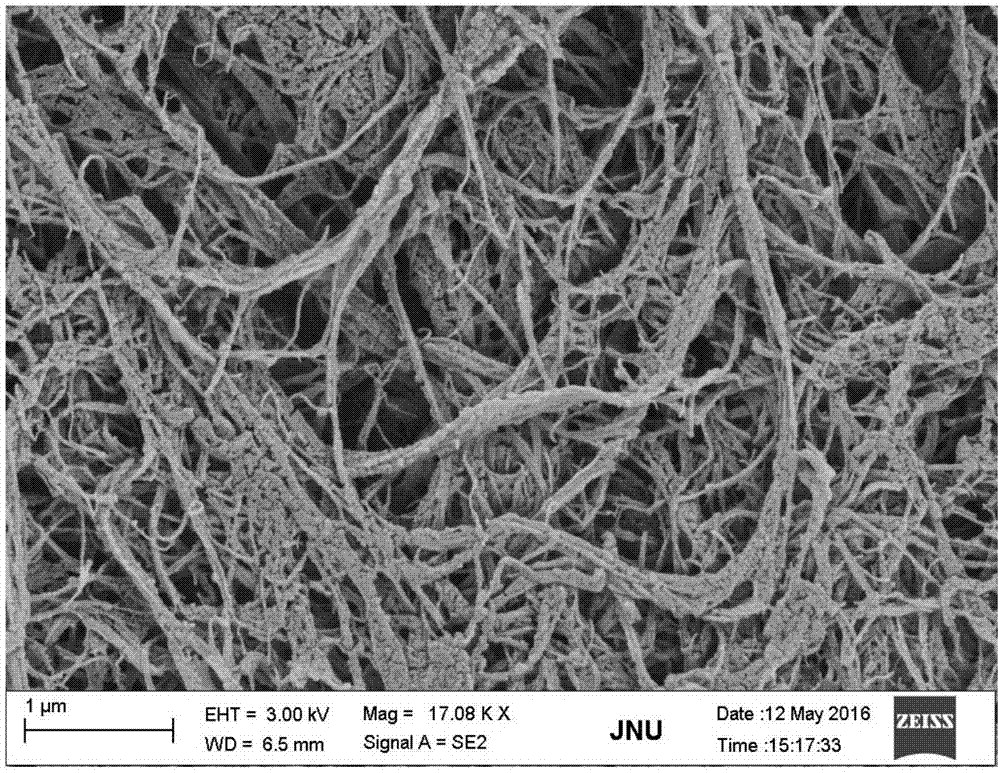

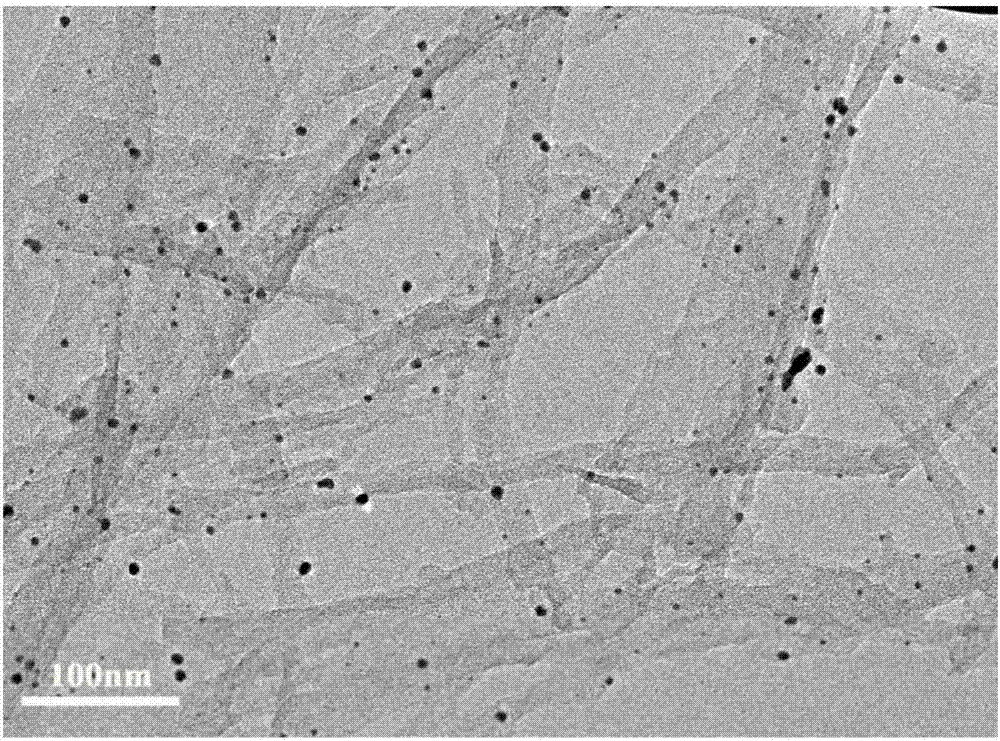

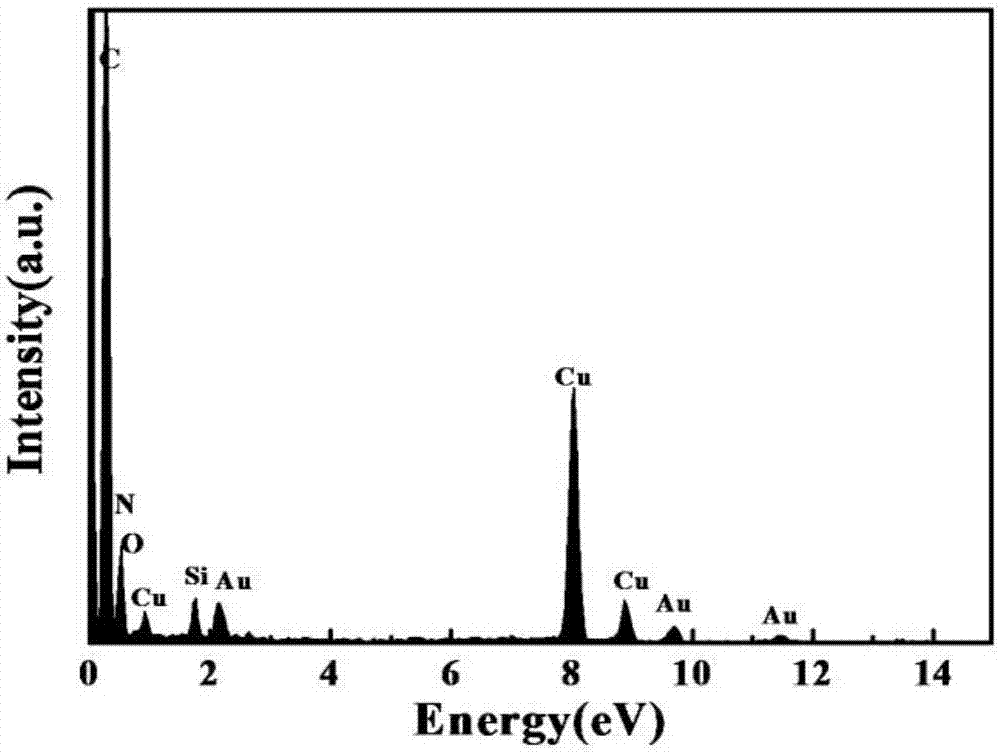

[0031] 2) freeze-dry the composite of bacterial cellulose and polydopamine, put it into a tube furnace for high-temperature carbonization to obtain nitrogen-doped carbon nanofibers, and then use sodium borohydride to chemically reduce the nitrogen-doped carbon nanofibers on the nitrogen-doped The carbon nanofiber supports the gold nanoparticle to obtain the nitrogen-doped carbon nanofiber supported gold nanoparticle oxygen reduction catalyst.

[0032] The preparation method of the catalyst is simple, and the oxygen reduction performance is excellent under alkaline conditions. Compared with the Pt catalyst, the catalyst h...

Embodiment 1

[0038] A preparation method of nitrogen-doped carbon nanofiber loaded gold nanoparticle oxygen reduction catalyst, comprising the following steps:

[0039] 1) Pretreatment of bacterial cellulose: Soak bacterial cellulose with deionized water until neutral, and cut into small pieces with a size of 2cm×2cm;

[0040] 2) Bacterial cellulose and polydopamine complex: take step 1) and add 50mL of 0.1mol L to the bacterial cellulose treated -1 In the dopamine aqueous solution, stir and mix evenly in a constant temperature water bath at 50°C, add 20mL of Tri-HCl buffer solution with pH=8.5, make the dopamine polymerize on the bacterial cellulose, and obtain the bacterial cellulose and polydopamine complex;

[0041] 3) Nitrogen-doped carbon nanofibers: freeze-dry the bacterial cellulose and polydopamine complexes obtained in step 2), and put them into a temperature-programmed tube furnace after drying under N 2 Under the protection of 1.5℃·min -1 After carbonization at a heating rate...

Embodiment 2

[0046] A preparation method of nitrogen-doped carbon nanofiber loaded gold nanoparticle oxygen reduction catalyst, comprising the following steps:

[0047] 1) Pretreatment of bacterial cellulose: Soak bacterial cellulose with deionized water until neutral, and cut into small pieces with a size of 2cm×2cm;

[0048] 2) Bacterial cellulose and polydopamine complex: take step 1) and add 50mL of 0.1mol L to the bacterial cellulose treated -1 In the dopamine aqueous solution, stir and mix evenly in a constant temperature water bath at 50°C, add 20mL of Tri-HCl buffer solution with pH=8.5, make the dopamine polymerize on the bacterial cellulose, and obtain the bacterial cellulose and polydopamine complex;

[0049] 3) Nitrogen-doped carbon nanofibers: freeze-dry the bacterial cellulose and polydopamine complexes obtained in step 2), and put them into a temperature-programmed tube furnace after drying under N 2 Under the protection of 1.5℃·min -1 After carbonization at a heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com