Oxygen reduction catalyst prepared based on tetra-beta-(4-formylphenoxy)phthalocyanine cobalt aerogel and preparation method thereof

A technology of aldehyde phenoxy and cobalt phthalocyanine, which is applied in the field of oxygen reduction catalyst and its preparation, and can solve the problems of restricting the development of fuel cells, scarcity of reserves, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1) Add 0.06 g of tetrakis-β-(4-formylphenoxy)cobalt phthalocyanine into 2 mL of N,N-dimethylformamide, and disperse ultrasonically in a 40KHz ultrasonic apparatus for 8 minutes to obtain a crosslinking agent solution.

[0055] 2) In 4g of a mixed aqueous solution containing 1wt% acetic acid and 3wt% chitosan, add the above-mentioned cross-linking agent solution, and obtain a dark green hydrogel after rapid shaking, soak the prepared hydrogel in 300mL deionized water Remove excess solvent for 6 hours, continue to soak in 10 mL of 5 mg / mL graphene oxide aqueous solution for 6 hours, and obtain a composite hydrogel by electrostatic adsorption.

[0056] 3) The obtained composite hydrogel was freeze-dried at -57°C for 18 hours to obtain a light green composite aerogel.

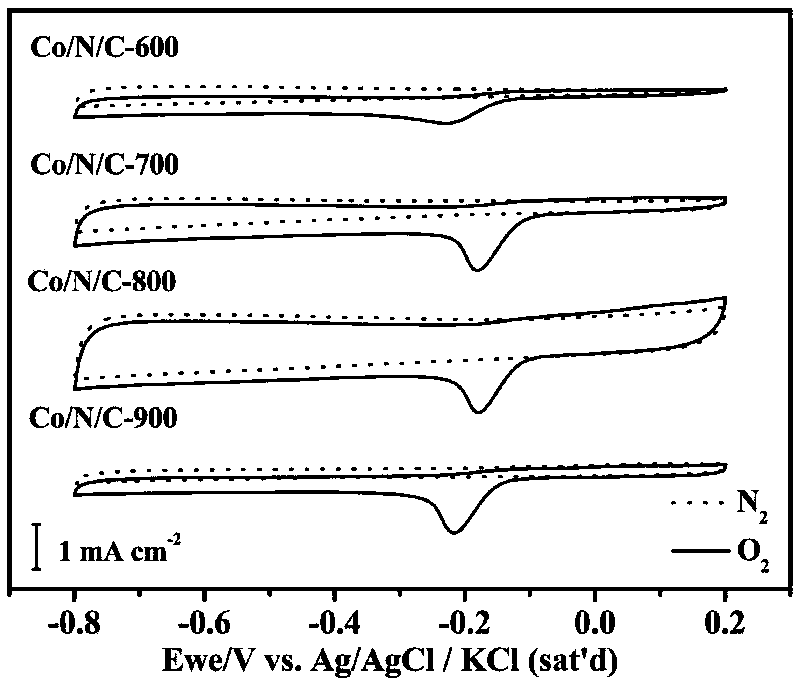

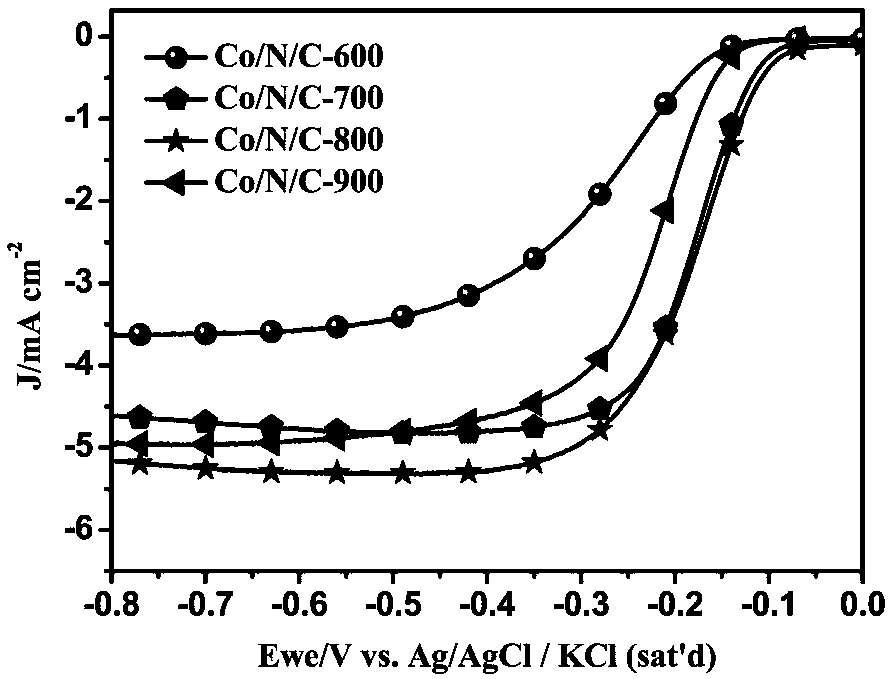

[0057] 4) Under the protection of high-purity argon, the obtained composite airgel was subjected to high-temperature heat treatment at 600°C, 700°C, 800°C, and 900°C for 2 hours to obtain a black powder prod...

Embodiment 2

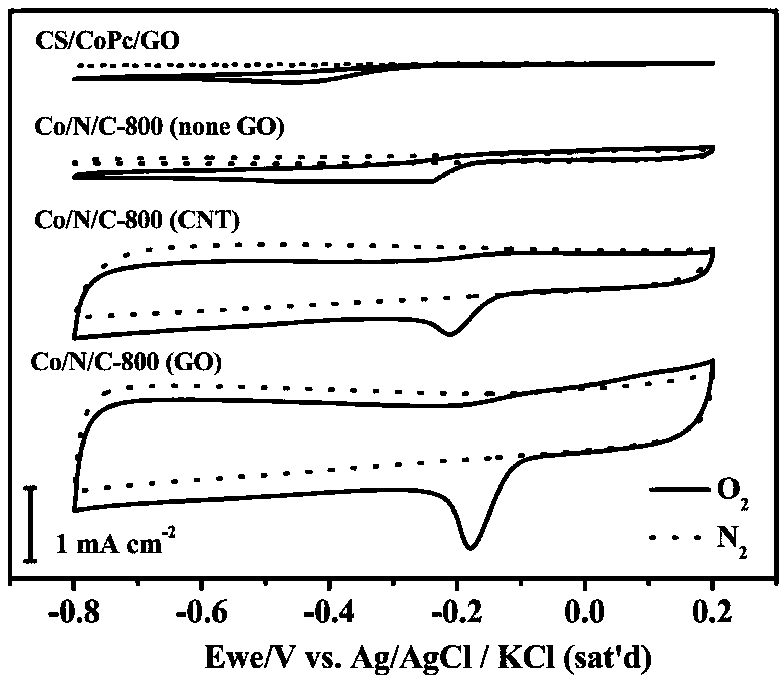

[0062] Sample 1: CS / CoPc / GO

[0063] 1) Add 0.06g tetrakis-β-(4-formylphenoxy) cobalt phthalocyanine to 2mL N,N-dimethylformamide, and ultrasonically disperse in a 40KHz ultrasonic apparatus for 10min to obtain a crosslinking agent solution.

[0064] 2) In 4g of mixed aqueous solution containing 1wt% acetic acid and 3wt% chitosan, add the above-mentioned crosslinking agent solution, and obtain dark green hydrogel after rapid shaking, soak the prepared hydrogel in 300mL deionized water Remove excess solvent for 6 hours, continue soaking in 10ml of 5mg / mL graphene oxide aqueous solution for 6 hours, and obtain composite hydrogel by electrostatic adsorption.

[0065] 3) After the obtained composite hydrogel was freeze-dried at -57°C for 24 hours, the light green composite airgel was obtained, which was the sample CS / CoPc / GO.

[0066] Sample 2: Co / N / C-800(noneGO)

[0067] 1) Add 0.06g tetrakis-β-(4-formylphenoxy) cobalt phthalocyanine to 2mL N,N-dimethylformamide, and ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com