A nitrogen-containing amorphous carbon layer-wrapped carbon nanotube one-dimensional material with a core-shell structure and its preparation method and application

A technology of carbon nanotubes and amorphous carbon, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of low methanol resistance, high price, poor stability, etc., and achieve high temperature treatment The effect of short time, high safety and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

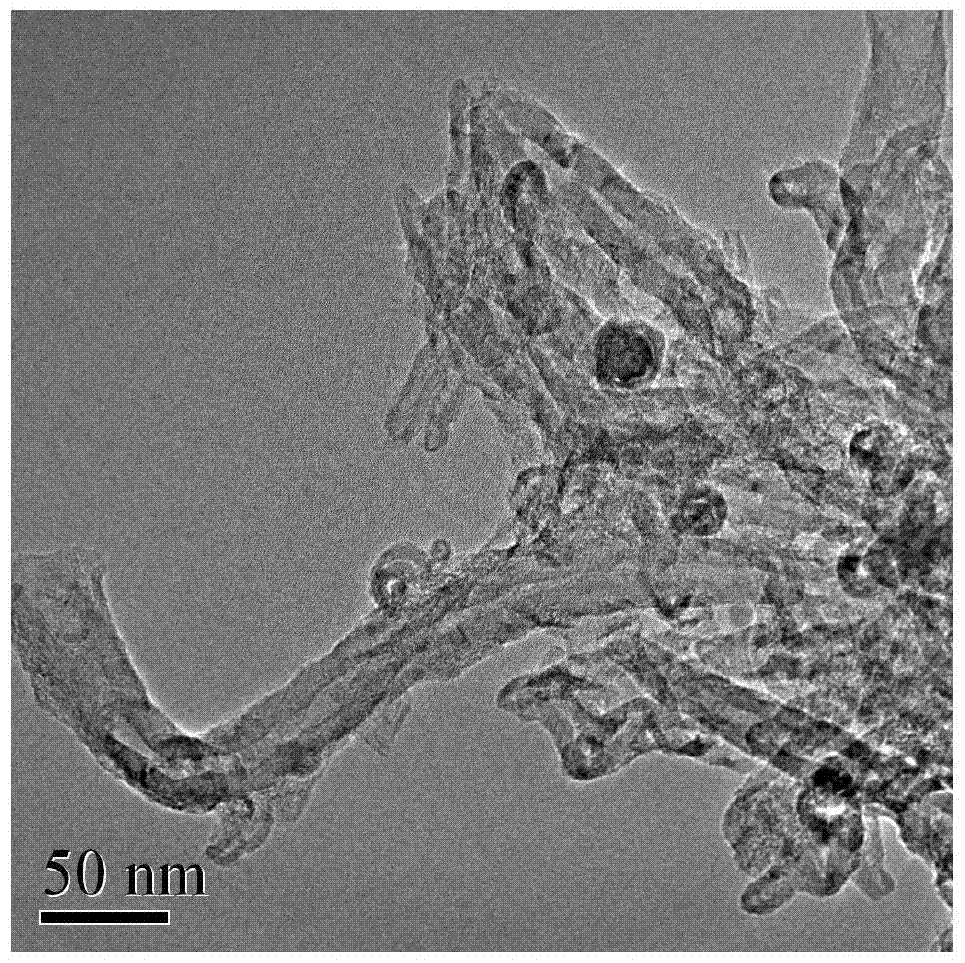

[0044] Disperse 200 mg of carboxylated carbon nanotubes in 2 mL of DMF and 40 mL of SOCl 2 In the mixed solution, the temperature was raised to 65 degrees Celsius and stirred for 24 hours, then centrifuged and dried. Ultrasonic dispersion of the above obtained product in 50 mL THF, adding 500 mg of p-phenylenediamine and refluxing for 24 hours, the obtained product was centrifuged and dried to obtain amino carbon nanotubes. Prepare ethanol solution 1 dissolved with terephthalaldehyde (4mg / mL) and acetic acid, and ethanol solution dissolved with 5, 10, 15, 20-tetrakis(4-aminophenyl) porphyrin (6mg / mL) and acetic acid Solution 2. Under ultrasonic conditions, ultrasonically disperse the amino-modified carbon nanotubes in solution 1 and keep ultrasonic for 30 min, then centrifuge; under ultrasonic conditions, ultrasonically disperse the material obtained by centrifugation in solution 2 and keep ultrasonic for 30 min, then centrifuge ; Repeat the above operation once, and heat an...

Embodiment 2

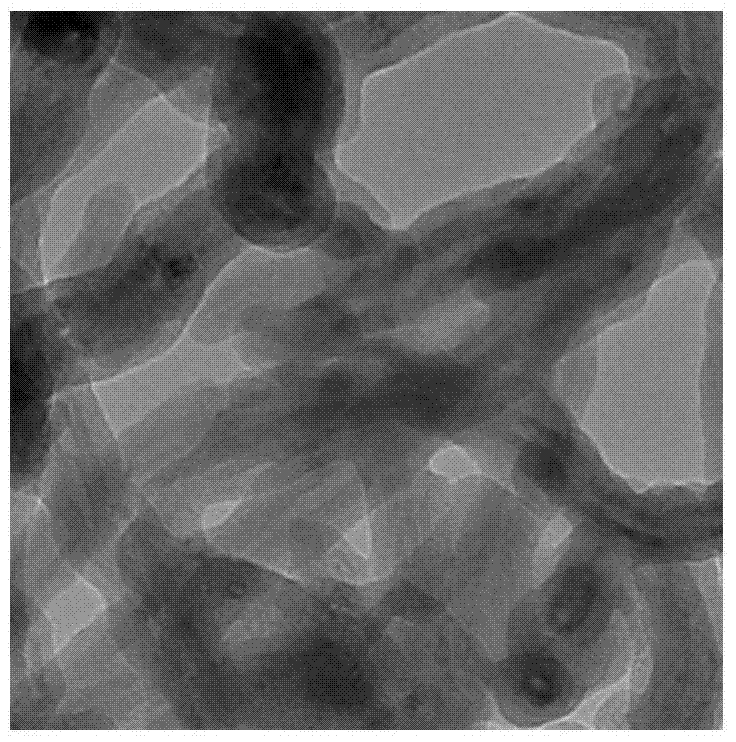

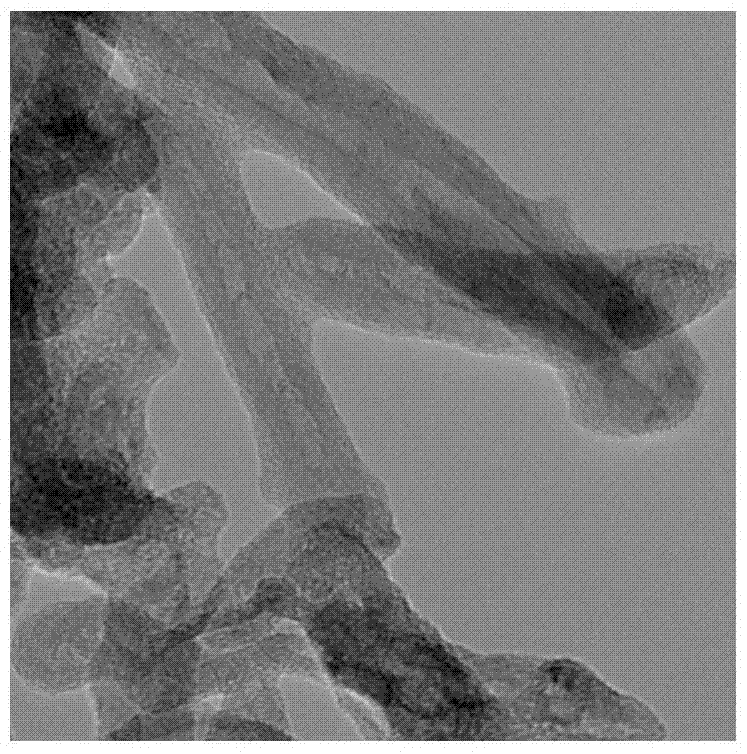

[0046] The preparation process of Example 1 is adopted, except that the amount of iron metal salt used is increased to 20-50 mg. Depend on Figure 4 It is known that the material obtained under this condition can observe iron nitride species through XRD characterization, and at the same time by image 3 Metal particles can also be clearly observed in TEM photographs. Its oxygen reduction reaction activity is shown in Figure 5 , the limiting diffusion current can reach 5.7mA / cm 2 , the half-wave potential is about -0.15V.

Embodiment 3

[0048] The preparation process of Example 2 is adopted, except that the amount of iron metal salt used is increased to 50-80 mg. Depend on Figure 4 It is known that the material obtained under this condition can observe iron nitride and ferric oxide species through XRD characterization, and at the same time, metal particles can also be clearly observed on the TEM photo. Its redox reaction activity can be seen in Figure 5 , the limiting diffusion current can reach 5.0mA / cm 2 , the half-wave potential is about -0.2V.

[0049] The invention relates to a nitrogen-containing amorphous carbon layer-wrapped carbon nanotube oxygen reduction catalyst with a core-shell structure, a preparation method and application thereof. Specifically, the surface of carbon nanotubes is coated with a layer of porphyrin formed by the reaction of terephthalaldehyde and 5, 10, 15, 20-tetrakis (4-aminophenyl) porphyrin monomers through the condensation reaction of amino-aldehyde groups. polymer. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com