A PD-based passivation film with high catalytic activity and preparation method thereof

A high catalytic activity, passivation film technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as poor catalytic stability, and achieve the effects of structural stability, high cycle stability, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A Pd-based passivation film with high catalytic activity, the passivation film comprises the following components according to atomic percentage:

[0033] Pd 90%,

[0034] Ni 10%.

[0035] in:

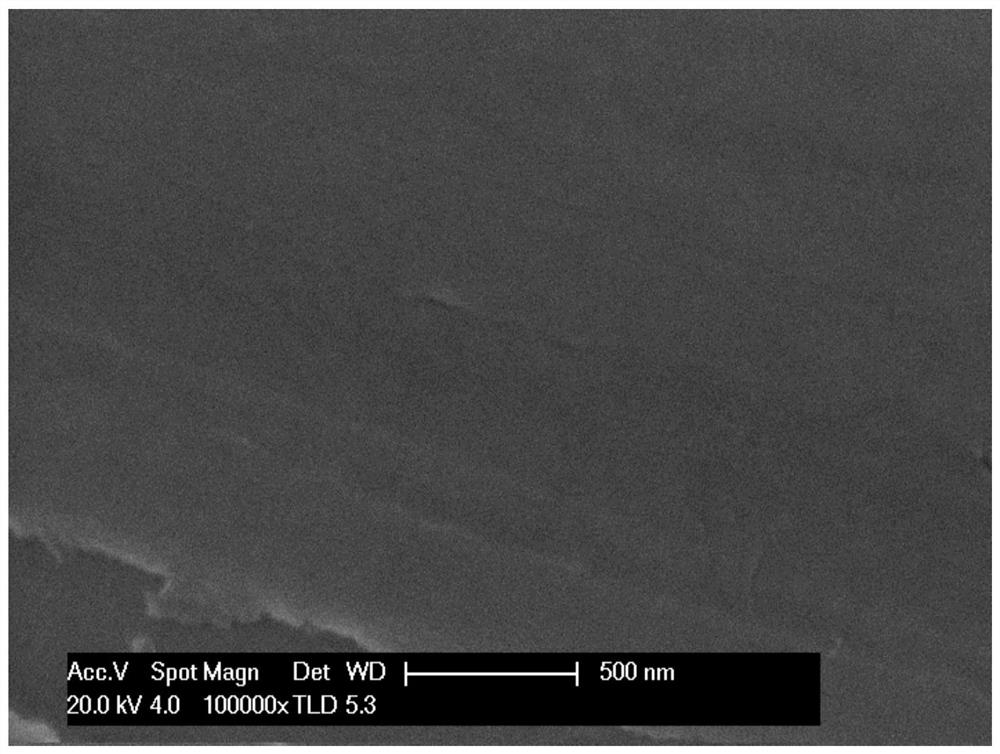

[0036] The surface roughness of the passivation film was 170 and the thickness was 500 nm.

[0037] Its preparation method comprises the following steps:

[0038] 1) Put the Pd 20 Ni 80 The uniform solid solution was polished under the condition of 50kPa for 5 minutes to make the surface smooth and inject residual stress to obtain the polished sample;

[0039] 2) Place the polished sample in H 2 SO 4 and NiSiO 4 mixture (where H 2 SO 4 The concentration is 0.5M, NiSiO 4 Electrochemical corrosion was carried out in the concentration of 0.0001M), the corrosion voltage range was 550mV relative to the reversible hydrogen electrode, and after corrosion for 3000 seconds, the passive film was obtained by removing and cleaning;

[0040] 3) Place the passivation film in oxyge...

Embodiment 2

[0043] A Pd-based passivation film with high catalytic activity, the passivation film comprises the following components according to atomic percentage:

[0044] Pd 80%,

[0045] Ni 20%.

[0046] in:

[0047] The surface roughness of the passivation film was 250 and the thickness was 300 nm.

[0048] Its preparation method comprises the following steps:

[0049] 1) Put the Pd 25 Ni 75 The uniform solid solution was polished under the condition of 20kPa for 5min to make the surface smooth and inject residual stress to obtain the polished sample;

[0050] 2) Place the polished sample in H 2 SO 4 and NiSiO 4 mixture (where H 2 SO 4 The concentration is 1M, NiSiO 4 Electrochemical corrosion was carried out in the concentration of 0.0006M), the corrosion voltage range was 650mV relative to the reversible hydrogen electrode, and after corrosion for 5000 seconds, the passive film was obtained by removing and cleaning;

[0051] 3) Place the passivation film in oxygen-satur...

Embodiment 3

[0054] A Pd-based passivation film with high catalytic activity, the passivation film comprises the following components according to atomic percentage:

[0055] Pd 90%,

[0056] Ni 9%,

[0057] Mo 1%.

[0058] in:

[0059] The surface roughness of the passivation film was 240 and the thickness was 300 nm.

[0060] Its preparation method comprises the following steps:

[0061] 1) Put the Pd 25 Ni 74.5 Mo 0.5 The uniform solid solution is polished under the condition of 20kPa for 10min to make the surface smooth and inject residual stress to obtain the polished sample;

[0062] 2) Place the polished sample in H 2 SO 4 and NiSiO 4 mixture (where H 2 SO 4 The concentration is 1M, NiSiO 4 Electrochemical corrosion was carried out in the concentration of 0.0005M), and the corrosion voltage range was 620mV relative to the reversible hydrogen electrode, and after corrosion for 5000 seconds, it was removed and cleaned to obtain a passivation film;

[0063] 3) Place the pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com