An oxygen reduction catalyst prepared based on tetra-β-(4-formylphenoxy)cobalt phthalocyanine airgel and its preparation method

A technology of aldehyde phenoxy and cobalt phthalocyanine, which is applied in the field of oxygen reduction catalysts and its preparation, can solve the problems of difficulty in maintaining large-scale production of fuel cells, limiting the development of fuel cells, and high prices, and achieves good oxygen reduction catalytic activity , good electrocatalytic performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1) Add 0.06 g of tetrakis-β-(4-formylphenoxy)cobalt phthalocyanine into 2 mL of N,N-dimethylformamide, and disperse ultrasonically in a 40KHz ultrasonic apparatus for 8 minutes to obtain a crosslinking agent solution.

[0055] 2) In 4g of a mixed aqueous solution containing 1wt% acetic acid and 3wt% chitosan, add the above-mentioned cross-linking agent solution, and obtain a dark green hydrogel after rapid shaking, soak the prepared hydrogel in 300mL deionized water Remove excess solvent for 6 hours, continue to soak in 10 mL of 5 mg / mL graphene oxide aqueous solution for 6 hours, and obtain a composite hydrogel by electrostatic adsorption.

[0056] 3) The obtained composite hydrogel was freeze-dried at -57°C for 18 hours to obtain a light green composite aerogel.

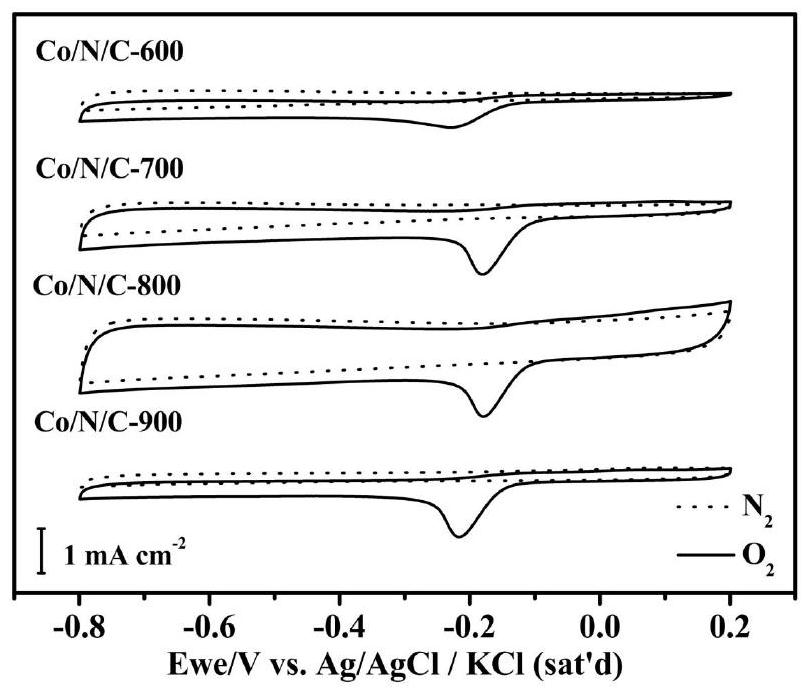

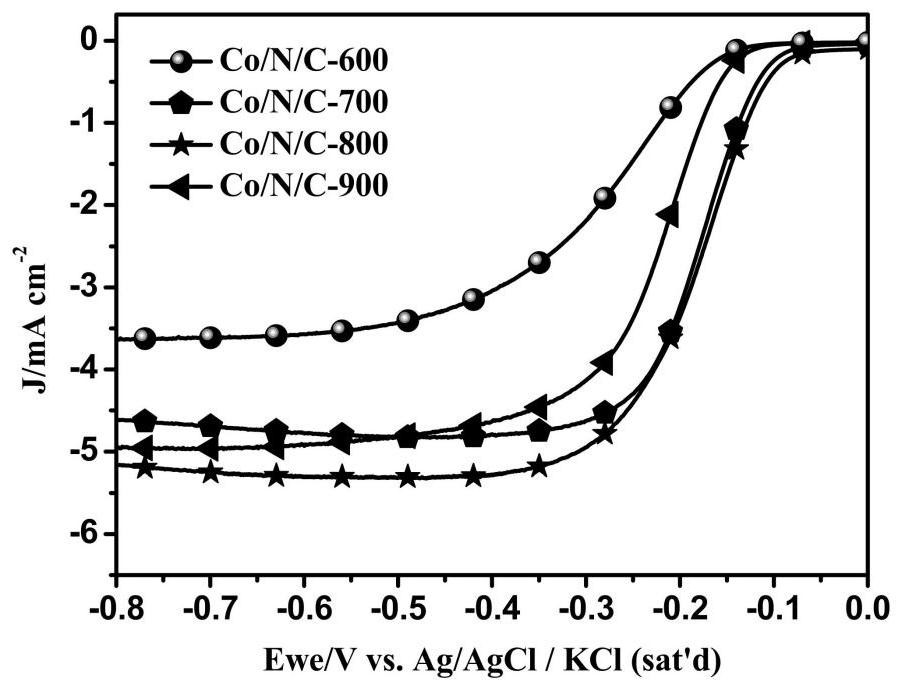

[0057] 4) Under the protection of high-purity argon, the obtained composite airgel was subjected to high-temperature heat treatment at 600°C, 700°C, 800°C, and 900°C for 2 hours to obtain a black powder prod...

Embodiment 2

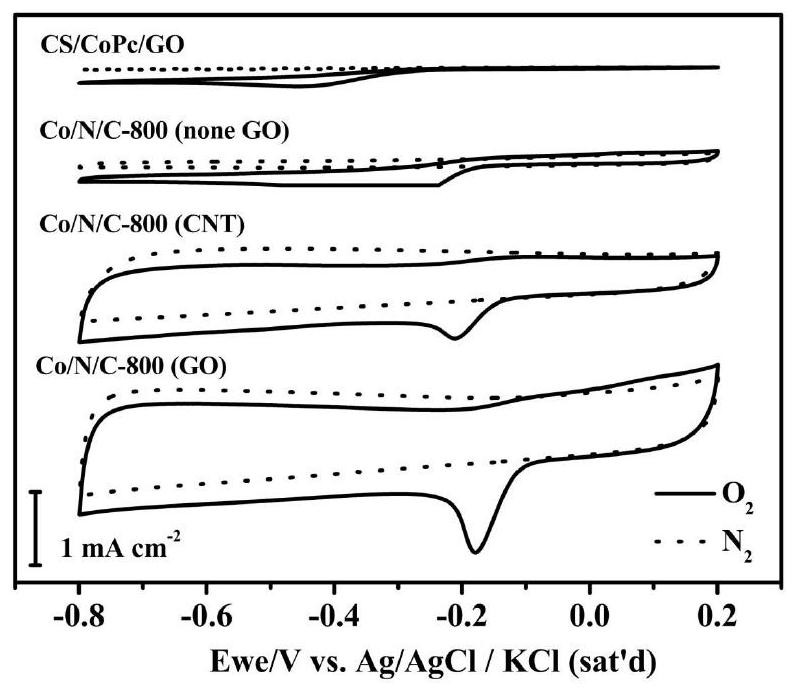

[0062] Sample 1: CS / CoPc / GO

[0063] 1) Add 0.06g tetrakis-β-(4-formylphenoxy)cobalt phthalocyanine to 2mL N,N-dimethylformamide, and ultrasonically disperse in a 40KHz ultrasonic apparatus for 10min to obtain a crosslinking agent solution.

[0064] 2) In 4g of a mixed aqueous solution containing 1wt% acetic acid and 3wt% chitosan, add the above-mentioned crosslinking agent solution, and obtain a dark green hydrogel after rapid shaking, soak the prepared hydrogel in 300mL deionized water Remove excess solvent for 6 hours, continue soaking in 10ml of 5mg / mL graphene oxide aqueous solution for 6 hours, and obtain composite hydrogel by electrostatic adsorption.

[0065] 3) After the obtained composite hydrogel was freeze-dried at -57°C for 24 hours, the light green composite airgel was obtained, which was the sample CS / CoPc / GO.

[0066] Sample 2: Co / N / C-800(noneGO)

[0067] 1) Add 0.06g tetrakis-β-(4-formylphenoxy)cobalt phthalocyanine to 2mL N,N-dimethylformamide, and ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com