Nitric acid modified porous carbon and applications thereof

A porous carbon and modification technology, applied in other chemical processes, petroleum wax refining, chemical instruments and methods, etc., can solve the problems of patents and literatures that have not been reported, and achieve the effect of low price, high adsorption capacity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

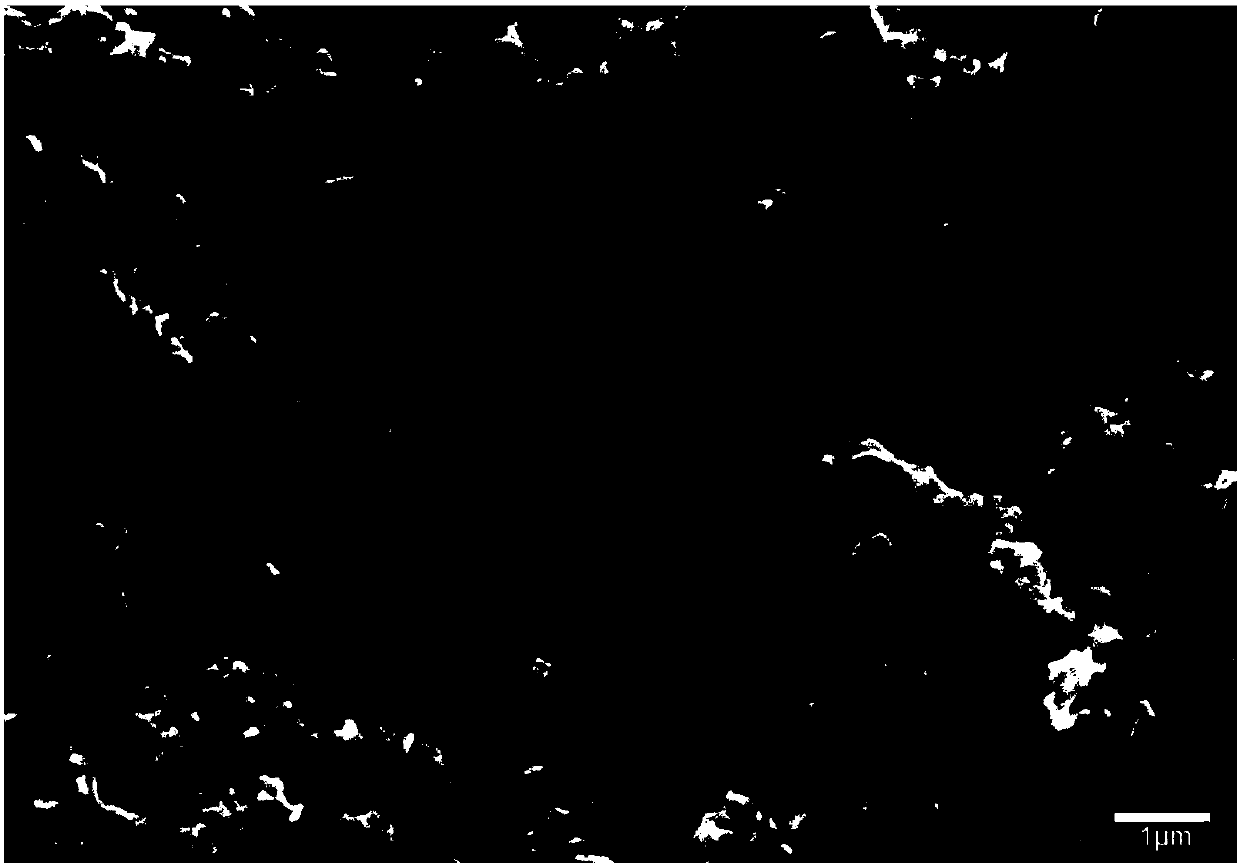

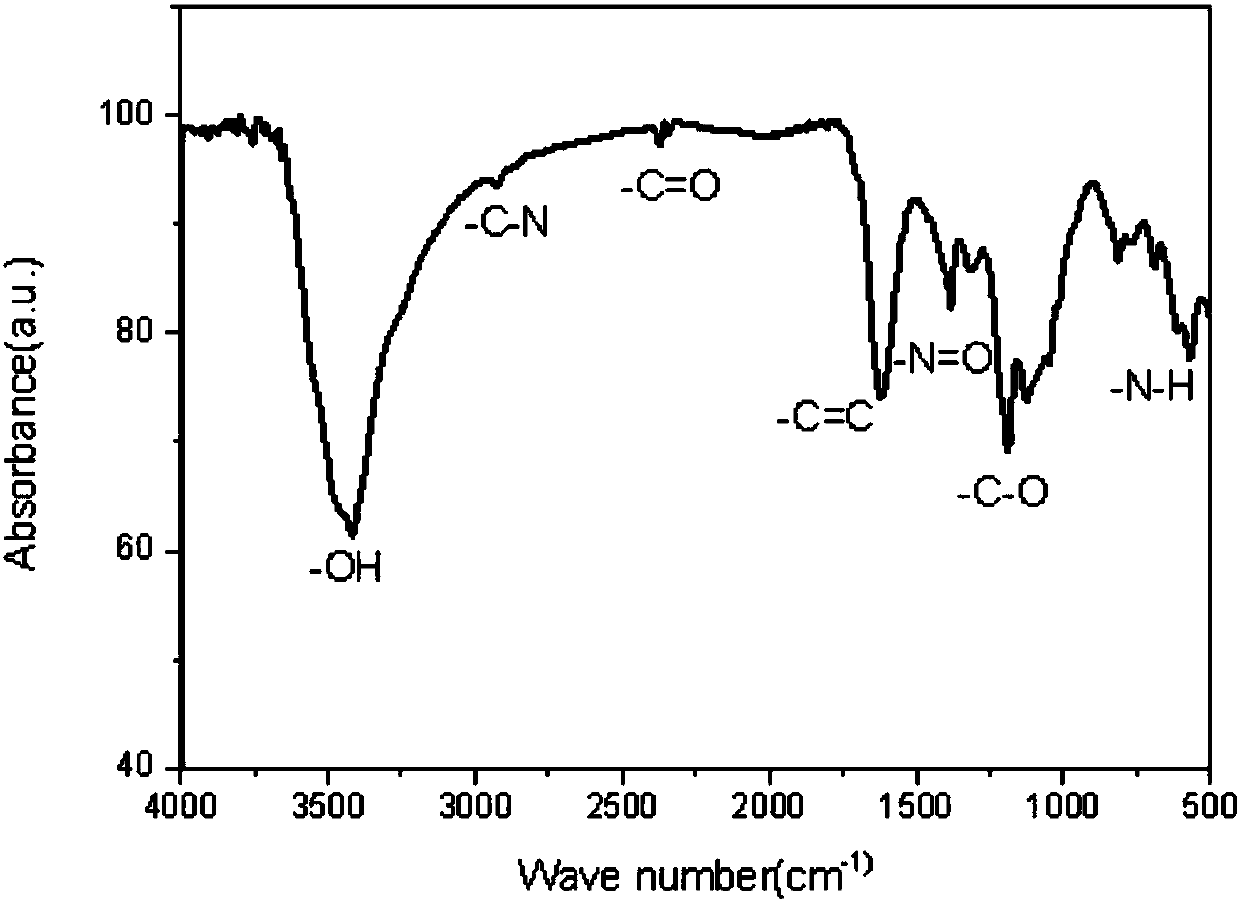

Image

Examples

Embodiment 1

[0038] A kind of porous carbon modified by nitric acid, the steps of its preparation method are:

[0039] 1. Synthesis of N-doped porous carbon:

[0040] 1.1. Add 0.03mol of melamine and 0.01mol of calcium citrate into 15mL of water, stir and mix well to obtain a liquid mixture, transfer the liquid mixture to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction, and the reaction temperature is 150°C. The reaction time is 48 hours. After the reaction is completed, the precursor is obtained and dried;

[0041] 1.2. Put the dried precursor in the N 2 In the tube furnace, ensure that the tube furnace has good airtightness. At the same time, the temperature is raised to 850°C, the heating rate is 2°C / min, and the heat preservation is roasted for 2 hours. After the roasting is completed, the black powder obtained by roasting is etched with 10wt% hydrochloric acid. Treat (soak) for 12 hours, and wash with deionized water until the pH of the obtained filtrate is 7...

Embodiment 2

[0059] A kind of porous carbon modified by nitric acid, the steps of its preparation method are:

[0060] 1. Synthesis of N-doped porous carbon:

[0061] 1.1. Add 0.03mol of melamine and 0.01mol of calcium citrate into 15mL of water, stir and mix well to obtain a liquid mixture, transfer the liquid mixture to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction, and the reaction temperature is 150°C. The reaction time is 48 hours. After the reaction is completed, the precursor is obtained and dried;

[0062] 1.2. Put the dried precursor in the N 2 In the tube furnace, ensure that the tube furnace has good airtightness. At the same time, the temperature is raised to 850 °C, the heating rate is 2 °C / min, and the heat preservation is roasted for 2 hours. The black powder obtained by roasting is etched by hydrochloric acid with a mass fraction of 10 wt%. Treat (soak) for 12 hours, and wash with deionized water until the pH of the obtained filtrate is 7, and dr...

Embodiment 3

[0066] A kind of porous carbon modified by nitric acid, the steps of its preparation method are: 1, the synthesis of N-doped porous carbon:

[0067] 1.1. Add 0.03mol of melamine and 0.01mol of calcium citrate into 15mL of water, stir and mix well to obtain a liquid mixture, transfer the liquid mixture to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction, and the reaction temperature is 150°C. The reaction time is 24 hours. After the reaction is completed, the precursor is obtained and dried;

[0068] 1.2. Put the dried precursor in the N 2 In the tube furnace, ensure that the tube furnace has good airtightness. At the same time, the temperature is raised to 850 °C, the heating rate is 2 °C / min, and the heat preservation is roasted for 2 hours. The black powder obtained by roasting is etched by hydrochloric acid with a mass fraction of 10 wt%. (soaking) for 12 hours, and washing with deionized water until the pH of the obtained filtrate is 7, and drying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com