Grinding medium for chemico-mechanical polishing and preparation thereof

A chemical mechanical and chemical polishing technology, applied in chemical instruments and methods, inorganic pigment treatment, polishing compositions containing abrasives, etc., can solve problems such as only attracting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

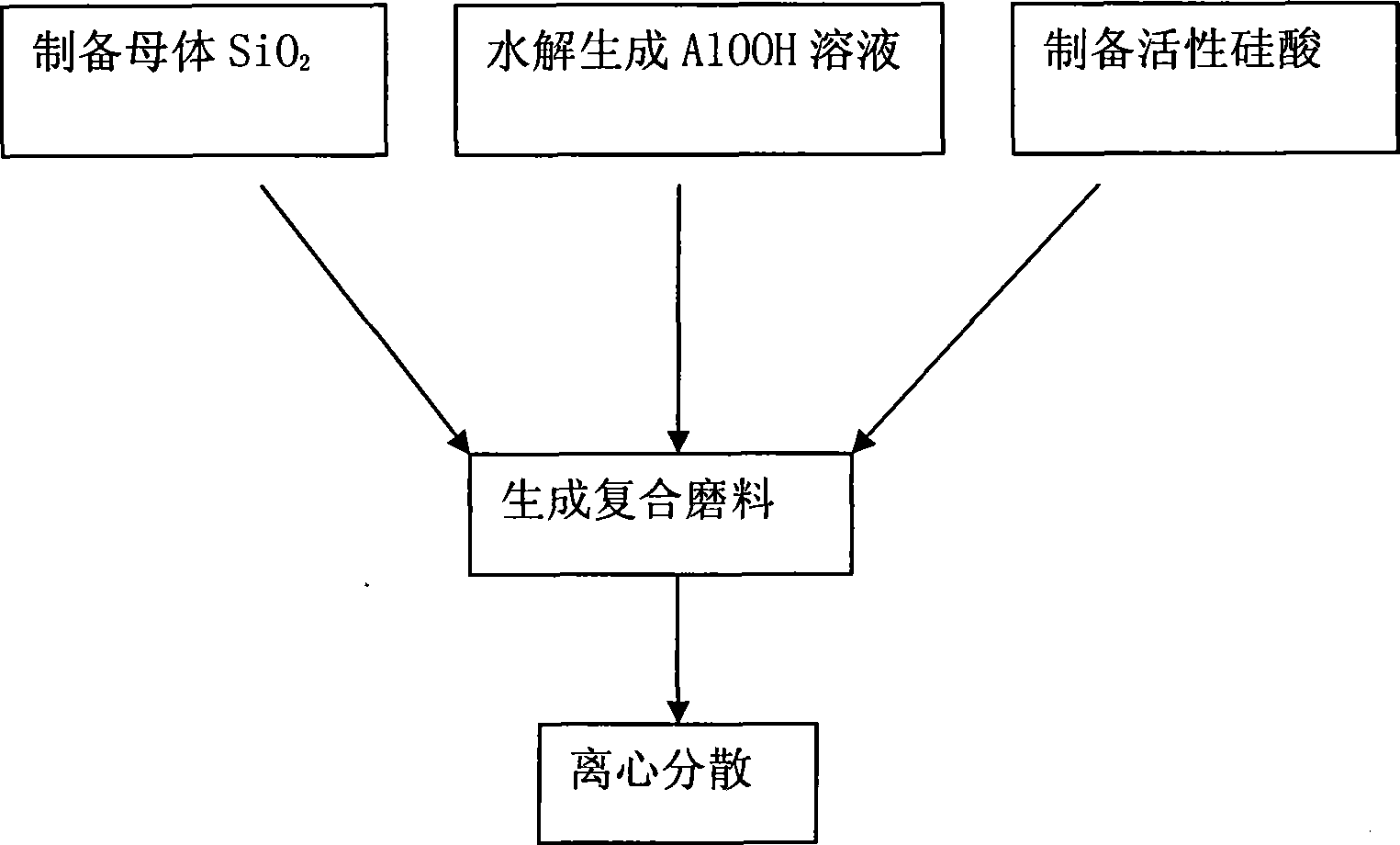

[0025] The invention is an aluminum-silicon composite coated SiO 2 Abrasive and preparation method, it comprises the following steps:

[0026] (1) Preparation of parent SiO 2 . Choose commercial SiO 2 , and its particle size can be between 5-200 nanometers, or between 20-100 nanometers, preferably 50-100 nanometers. Or 5-50 nanometers, or 100-200 nanometers. The pH value can be between 9-11. Dilute it into a 1%-5% colloidal solution, and adjust the pH value to about 10 with KOH or HCl.

[0027] (2) Hydrolysis generates AlOOH solution. For aluminum salt hydrolysis, it is best to use volatile organic aluminum salts, such as aluminum isopropoxide. Secondly, inorganic aluminum salts can be used. Grind thoroughly with a mortar, then add it into water according to the molar ratio of water and aluminum salt 200:1, and disperse by ultrasonic. Then put it in a four-necked flask and hydrolyze it for 1.5-2 hours at 81-89 degrees, raise the temperature to 90-95 degrees, and add a...

Embodiment 1

[0033] (1) Take 10ml of 30% 60nm silica sol, its pH value is 10.3. Dilute it 20 times. The pH was adjusted to 10 with KOH.

[0034] (2) Weigh 14g of aluminum isopropoxide, put it in a grinder and grind it thoroughly, add 400ml of water, heat and hydrolyze it in a four-necked flask for 1.5h at a temperature of 85 degrees, and circulate water. Heat up to 93 degrees, add HNO 3 Make the pH value and then heat at a constant temperature in the open for 24 hours to obtain 200 ml of a transparent aluminum sol with a pH value of 3.7.

[0035] (3) Measure 50ml of 40% water glass, dilute to 5%, add cation exchange column to obtain 408ml active silicic acid

[0036] (4) Put 200ml of the matrix abrasive obtained in (1) into a four-necked flask, heat to 85 degrees, and use a peristaltic pump to squeeze the aluminum sol obtained in (2) into a multi-necked flask at a rate of 2ml / sec. 200ml of active silicic acid obtained in (3) was added into (1) at 2ml / sec, and at the same time, the heat...

Embodiment 2

[0039](1) Take 10ml of 30% 100nm silica sol, its pH value is 10.2. Dilute it 20 times and adjust the pH to 10 with KOH.

[0040] (2) Weigh AlCl 3 9g, put it in a grinder and grind it thoroughly, add 400ml of water, put it in a four-necked flask and heat it for hydrolysis for 1.5h, the temperature is 85 degrees, and the water circulates. Heat up to 93 degrees, add HNO 3 Make the pH value and then heat at a constant temperature in the open for 24 hours to obtain 200 ml of a transparent aluminum sol with a pH value of 3.2.

[0041] (3) Measure 50ml of 40% water glass, dilute to 5%, add cation exchange column to obtain 408ml active silicic acid

[0042] (4) 200ml of matrix abrasive obtained in (1) is put into a multi-necked flask, heated to 85 degrees, and the aluminum sol obtained in (2) is squeezed into a multi-necked flask with a rate of 2ml / sec with a peristaltic pump, and the same The obtained 200ml active silicic acid was added into (1) at 2ml / sec, and at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com