Preparation method of continuous high quality soldering powder

A high-quality, soldering technology, applied in the field of alloy preparation, can solve problems affecting product quality and increasing production costs, and achieve the effects of environmental protection, quality improvement, and production labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

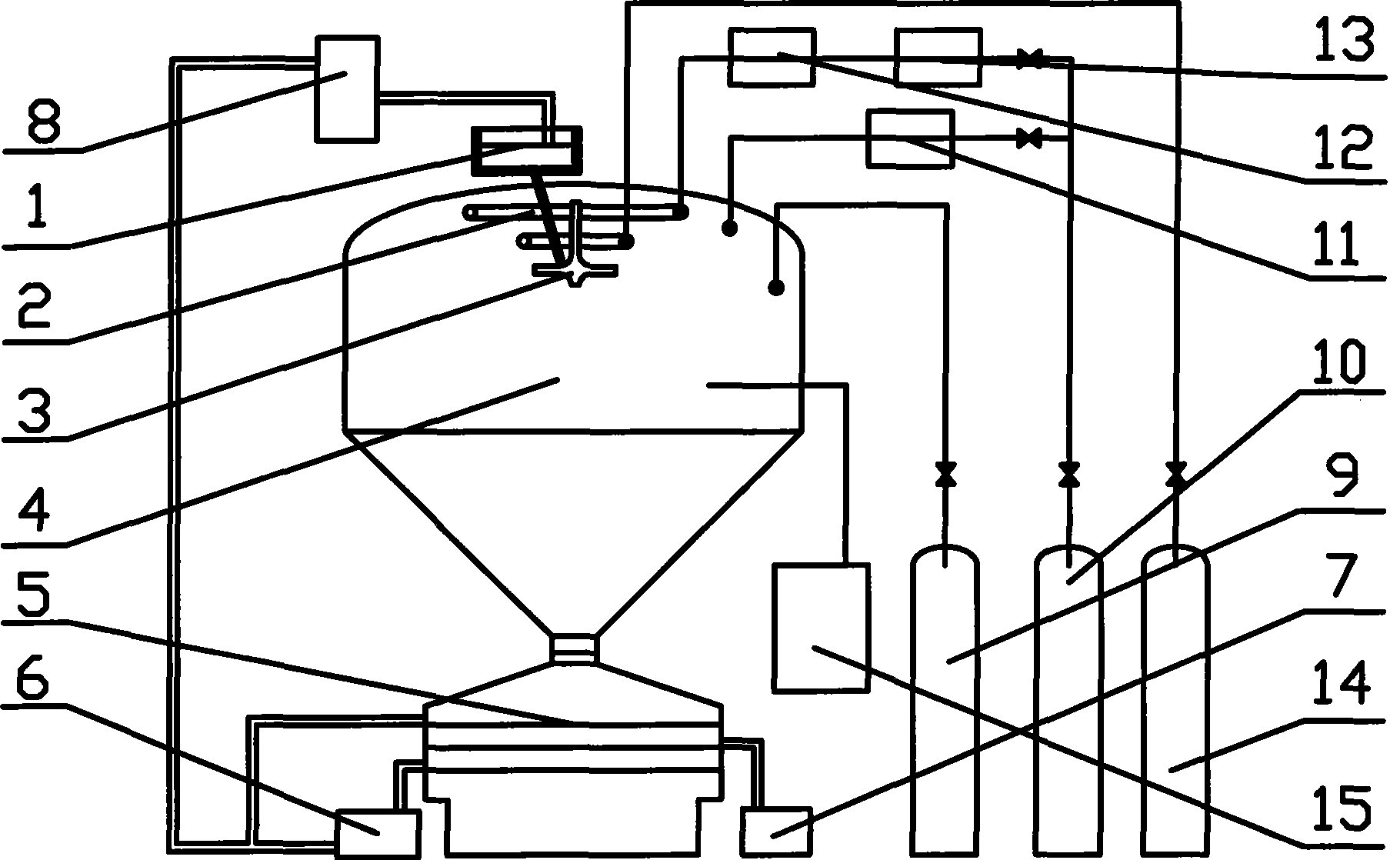

[0030] The production process of tin alloy powder is as follows:

[0031]First, use the vacuum system 15 to evacuate the atomization chamber 4, and then fill the atomization chamber 4 with protective gas from the gas source 10 until the indoor pressure is slightly higher than 1 atmospheric pressure; , inert gas 10, hydrogen gas 14, etc. are adjusted to the required concentration; the tin alloy material is melted with the alloy melting furnace 1, and the liquid is transported to the atomizer 3 through the infusion tube 2, and the atomizer 3 can be a centrifugal atomizer, Ultrasonic atomizer, electric pulse atomizer and gas atomizer, the atomizer 3 atomizes the tin alloy metal liquid into tiny droplets; the atomized droplets solidify into solid metal when flying in the atomization chamber 4 The solidification of powder and liquid droplets is controlled by factors such as the temperature and atmosphere in the atomization chamber 4; then the metal powder is transported to the mult...

Embodiment 2

[0038] Production of Sn63Pb37 Alloy Powder

[0039] Will figure 1 After the equipment in the vacuum is evacuated, at 25m 3 Fill the atomization chamber 4 with nitrogen at an inflation rate of / h, adjust the oxygen atmosphere in the atomization chamber 4 to 200ppm with the oxygen supply / oxygen meter 9, the temperature of the Sn63Pb37 alloy in the alloy melting furnace 1 is 250°C, and the liquid metal A rotary ultrasonic atomizer 3 with a frequency of 45KHz is introduced into the atomization chamber 4 at a speed of 100kg / h. The temperature in the atomization area is controlled at 60~80°C, and the temperature in the atomization chamber outside the atomization area is controlled to 40 below ℃. A 325-mesh and a 500-mesh screen are installed on the sieving machine 5, and after being sieved by the sieving machine 5 under the atomization chamber 4, the product flow rate of Type3# powder (-325~+500 mesh) with a standard particle size reaches 62kg / h. Other powders out of specificatio...

Embodiment 3

[0041] Production of Sn99Ag0.3Cu0.7 Alloy Powder

[0042] Will figure 1 After vacuumizing the equipment in the method, fill the atomization chamber 4 with nitrogen at an inflation rate of 30m3 / h, and adjust the oxygen atmosphere in the atomization chamber 4 to 800ppm with the oxygen supply / oxygen meter 9, wherein the atomization area The oxygen atmosphere concentration is adjusted to 80ppm, the temperature of the Sn99Ag0.3Cu0.7 alloy in the alloy melting furnace 1 is 290°C, and the liquid metal is introduced into the centrifugal atomizer 3 in the atomization chamber 4 at a speed of 120kg / h. The speed of 3 is 60000rpm, the temperature in the atomization area is controlled below 40°C, and the temperature in the atomization room outside the atomization area is the free temperature. A 400-mesh and a 625-mesh screen are installed on the sieving machine 5, and after being sieved by the sieving machine 5 under the atomization chamber 4, the product flow rate of Type4# powder (-400~+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com