Method for glass micro-crack detection by molecule stainer

A detection method and coloring agent technology, which is applied in the direction of optical testing for defects/defects, can solve the problems of time-consuming, manpower and material resources, and achieve the effects of saving processing time, reducing processing costs, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

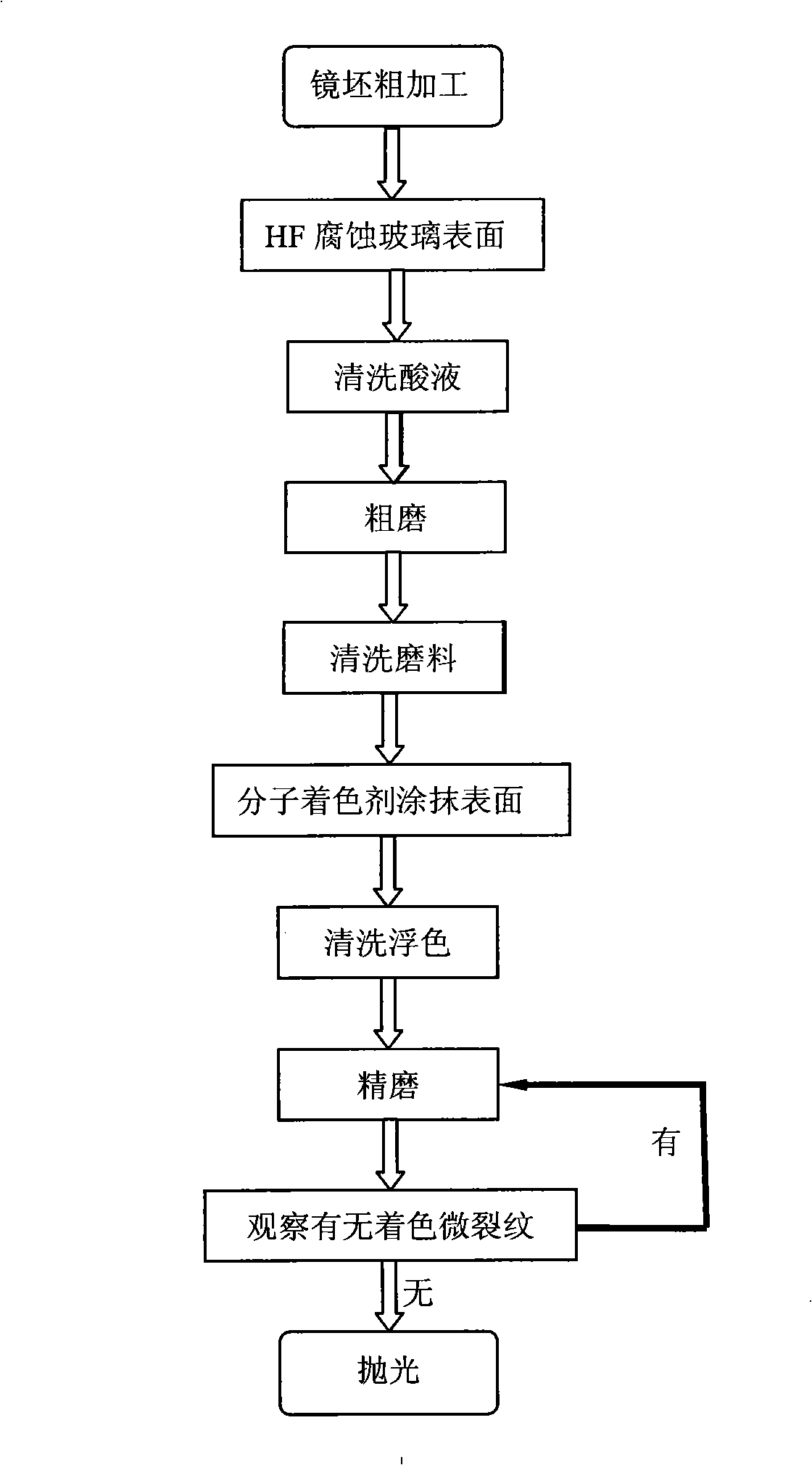

Image

Examples

Embodiment Construction

[0025]1. After rough processing, clean the glass surface to remove surface adsorbed substances, place it on a dry, ventilated and vibration-isolated platform, keep the environment clean, and place it for a period of time (24~48h) to release part of the processing stress.

[0026] 2. After the stress release is complete, carry out HF surface erosion treatment. Its purpose is to chemically strengthen the surface of the glass, remove the surface convex and concave layer, and further remove the stress; in the case of the original crack depth unchanged, the radius of curvature of the micro-crack is increased, the crack tip becomes blunt, and the stress concentration is reduced and the strength is increased. ; Open the crack surface, open the crack channel, so that the colorant molecules can enter. HF acid is generally used at a concentration of 12% to 15%, and appropriate amount of H can also be added. 2 SO 4 (15% ~ 60%), reduce salt deposits dirty glass surface. The time for ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com