Dewaxing liquid for LED (light-emitting diode) manufacturing process

A wax liquid and process technology, which can be used in the manufacture of semiconductor/solid-state devices, the preparation of detergent mixture compositions, and detergent compounding agents, etc., can solve the problems of reducing yield, increasing yield, cracking, etc., to improve efficiency and long service life. , Highlight the effect of penetration and dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0026] Example and Comparative Example: A dewaxing liquid for LED manufacturing process.

[0027] The dewaxing liquids of Examples and Comparative Examples were prepared according to the compositions and mass percentages shown in Table 1 below. The preparation method is as follows: deionized water is firstly added to the stirring tank at normal temperature, other components are added in turn at a rotating speed of 60r / min, each material is put in and stirred until the system is clarified, and then the next material is added; all additions are completed. After that, continue stirring for 30 minutes. Then, it is filtered through two filter elements of 5 μm and 0.5 μm in turn, and finally the dewaxing liquid is obtained.

[0028]

[0029] AOS--C 14-16 Sodium Alkenyl Sulfonate; NaCS--Sodium Cumene Sulfonate; IPA--Isopropanol;

[0030] DHMP--2,6-Dihydroxymethylpyridine; SCDH--Sodium Citrate Dihydrate;

[0031] MOA-9P--fatty alcohol ether phosphate; SAS--sodium secondary alk...

experiment example

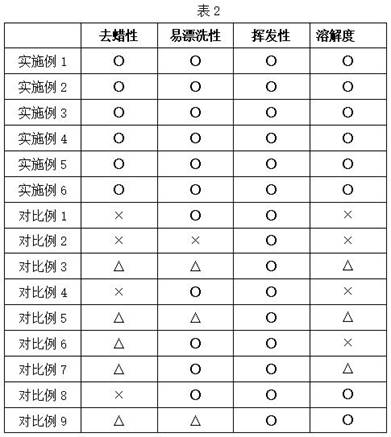

[0033] Experimental example: Determination of the performance of wax removal solution

[0034] In order to evaluate the performance of several dewaxing liquid compositions of Examples 1-6 and Comparative Examples 1-9 above, tests were conducted by the following tests.

[0035] 1. Evaluation of wax removal performance at low working temperature (55℃)

[0036] Usually, in order to ensure the removal of the bonding wax, the working temperature of the wax removal solution is increased (usually 80 °C), so that the bonding wax is easier to melt, and a better wax removal effect will be obtained. However, the higher working temperature will cause the slightly warped wafer to be easily broken due to thermal expansion and contraction in the subsequent cleaning. This experiment is used to test the wax removal effect of wax removal solution under low working conditions.

[0037] The wax removal solution was added to the ultrasonic cleaning tank and heated to 55°C. Adjust the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com