Preparation method of composite carbon nanofibers with high specific surface area

A technology of nano-carbon fiber and high specific surface, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems such as electrode materials of activated carbon fiber supercapacitors that have not been seen, and achieve improved pore structure and source The effect of enriching and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

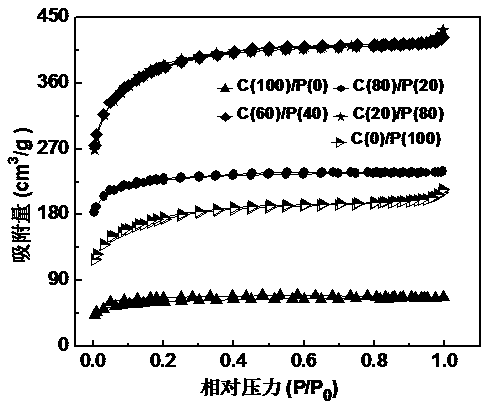

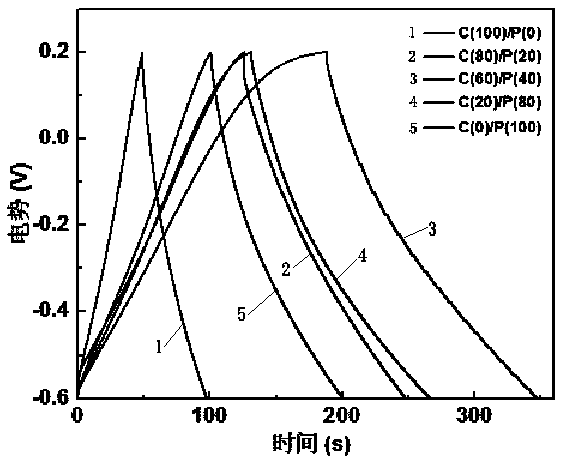

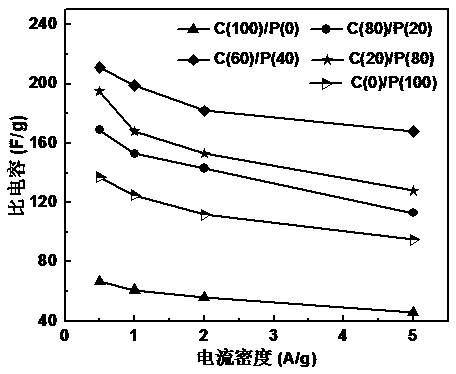

example 1

[0027] Electrospinning: Weigh 3g of cellulose acetate into a conical flask, add 27g of DMF (dimethylformamide), stir magnetically at 60°C for 4h and then let it stand for 1h to obtain a uniform and transparent mass fraction 10% spinning solution. The ambient temperature of electrospinning is ≤40°C, the humidity is ≤30%, the spinning voltage: 16kV, the spinning speed: 0.1mm / min, and the spinning distance: 16cm.

[0028] Pre-oxidation: in an air atmosphere, the pre-oxidation temperature is 250°C, the heating rate is 1°C / min, and the holding time is 2h; carbonization: in a nitrogen atmosphere, the carbonization temperature is 800°C, the heating rate is 1°C / min, and the holding time is 2h; Activation: The activator is potassium hydroxide, the mass ratio of potassium hydroxide to carbon fiber is 3 / 4, and it is prepared into a 1wt% KOH solution to impregnate the carbon fiber for 2 hours, then dry at 150°C, and the activation temperature is 800°C under a nitrogen atmosphere. °C, the...

example 2

[0031] Electrospinning: Weigh 2.4g of cellulose acetate and 0.6g of PAN (polyacrylonitrile) into a conical flask, add 27g of DMF, stir magnetically at 60°C for 4h and then let it stand for 1h to obtain a uniform and transparent Spinning solution with a mass fraction of 10%. The ambient temperature of electrospinning is ≤40°C, the humidity is ≤30%, the spinning voltage: 18kV, the spinning speed: 0.2mm / min, and the spinning distance: 17cm.

[0032] Pre-oxidation: in an air atmosphere, the pre-oxidation temperature is 250°C, the heating rate is 2°C / min, and the holding time is 2h; carbonization: under a nitrogen atmosphere, the carbonization temperature is 800°C, the heating rate is 2°C / min, and the holding time is 2h; Activation: The activator is potassium hydroxide, the mass ratio of potassium hydroxide to carbon fiber is 3 / 4, and it is prepared into a 1wt% KOH solution to impregnate the carbon fiber for 2 hours, then dry at 150°C, and the activation temperature is 800°C under ...

example 3

[0035]Electrospinning: Weigh 1.8g of cellulose acetate and 1.2g of polyacrylonitrile into a conical flask, add 27g of DMF, stir magnetically at 60°C for 4h and then let it stand for 1h to obtain a uniform and transparent mass fraction 10% spinning solution. The ambient temperature of electrospinning is ≤40°C, the humidity is ≤30%, the spinning voltage: 19kV, the spinning speed: 0.3mm / min, and the spinning distance: 18cm.

[0036] Pre-oxidation: in an air atmosphere, the pre-oxidation temperature is 250°C, the heating rate is 3°C / min, and the holding time is 2h; carbonization: under a nitrogen atmosphere, the carbonization temperature is 800°C, the heating rate is 3°C / min, and the holding time is 2h; Activation: The activator is potassium hydroxide, the mass ratio of potassium hydroxide to carbon fiber is 3 / 4, and it is prepared into a 1wt% KOH solution to impregnate the carbon fiber for 2 hours, then dry at 150°C, and the activation temperature is 800°C under a nitrogen atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com