Catalyst grading method for preparation of maleic anhydride from n-butane by oxidation

A catalyst, n-butane technology, applied in the field of n-butane production of maleic anhydride, can solve the problems of reducing the effective volume of the reactor, increasing the product yield, reducing the production efficiency, etc., and achieves reducing the hot spot of the reaction, improving the efficiency, and suppressing a large number of concentrated exothermic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (2) Preparation of vanadium phosphorus oxygen catalyst

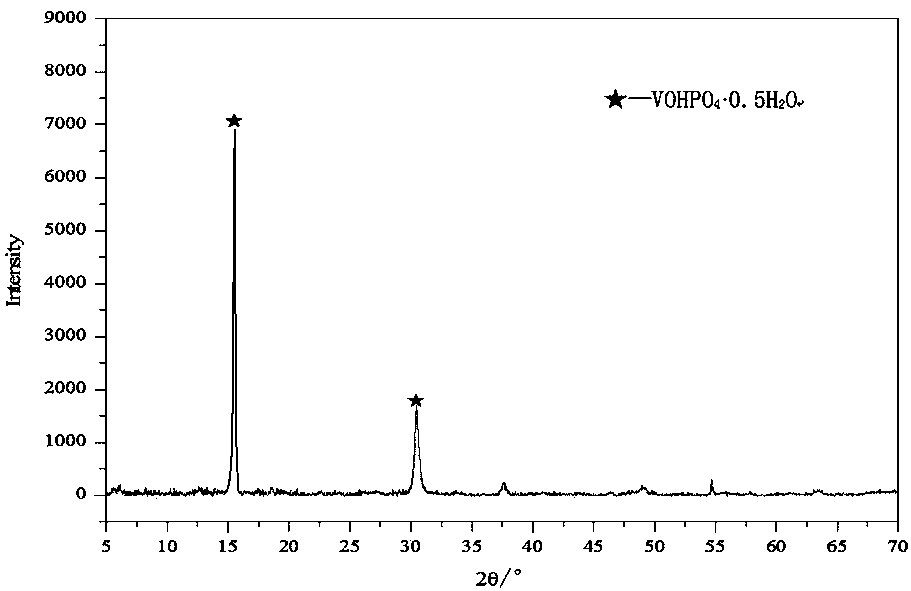

[0043] The vanadium phosphorus oxide obtained in step (1) is first shaped, and the shape of the obtained vanadium phosphorus oxygen catalyst can be a compressed tablet, a spherical shape, an extruded rod, etc., and the phase of the obtained catalyst precursor is (VOHPO 4 0.5H 2 o).

[0044] (3) Activation treatment of vanadium phosphorus oxygen catalyst

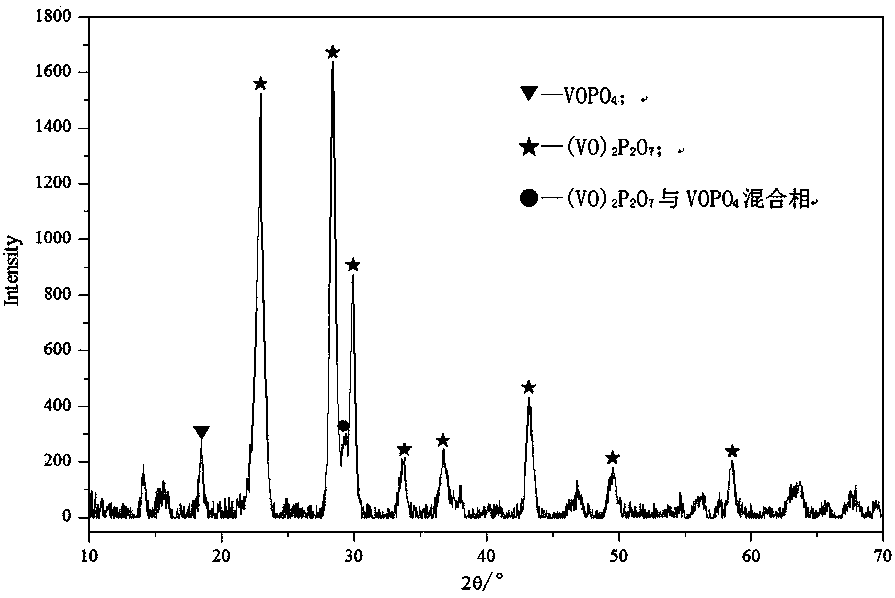

[0045] The shaped catalyst is placed in a tubular reactor, under the n-butane / air atmosphere with n-butane content of 0.6% (v), keep n-butane / air volume space velocity 500h -1 , the heating rate is 2°C / min, the activation temperature is raised from room temperature to 400°C for roasting treatment, and kept at 400°C for 40 hours, the activation process is completed, and the green vanadium phosphorus oxide catalyst of the present invention is obtained. The phase of the catalyst is (VO) 2 P 2 O7 phase, and a small amount of VOPO 4 Mutually.

[0046] The vanad...

Embodiment 1

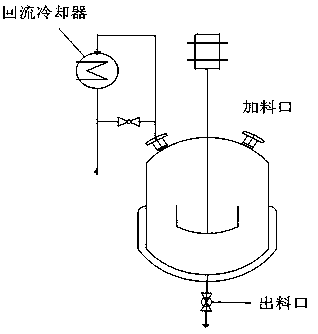

[0050] exist figure 1 Add 442.95 kg of isobutanol, 29.53 kg of vanadium pentoxide, 0.3 kg of ferric nitrate hexahydrate, and 0.5 kg of zirconium nitrate into the reaction kettle shown with a stirring device and a reflux condensing device. High reaction temperature and kept at 100±2°C, carry out reflux reaction, keep reflux time for 4 hours, then add 47.50kg of phosphoric acid with a concentration of 85%, the phosphorus / vanadium molar ratio is 1.27, continue to reflux for 8 hours, and the reaction ends. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed with a small amount of isobutanol three times, then the filter cake was placed in an enamel tray and dried naturally at room temperature, dried in an oven at 100°C for 8 hours, and finally dried in a muffle furnace. Calcined at 250°C for 5 hours to obtain a dark brown catalyst precursor.

[0051] Add the catalyst precursor prepared above to graphite powder with a m...

Embodiment 2

[0055] exist figure 1Add 442.95 kg of isobutanol, 29.53 kg of vanadium pentoxide, 0.3 kg of ferric nitrate hexahydrate, and 0.5 kg of zirconium nitrate into the reaction kettle shown with a stirring device and a reflux condensing device. High reaction temperature and kept at 100±2°C, carry out reflux reaction, keep reflux time for 4 hours, then add 44.13kg of phosphoric acid with a concentration of 85%, the phosphorus / vanadium molar ratio is 1.18, continue to reflux for 8 hours, and the reaction ends. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed three times with a small amount of isobutanol to complete the reaction. The filter cake was put into an enamel dish and air-dried at room temperature, dried in an oven at 100°C for 8 hours, and finally calcined in a muffle furnace at 250°C for 5 hours to obtain a dark brown catalyst precursor.

[0056] Add the catalyst precursor prepared above to graphite powder wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com