Design method for improving shaft hole connection structure bearing capacity

A technology of connection structure and design method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of unsuitable analysis and calculation of shaft-hole connection structure, easy to reach the strength limit of the hole edge, not taking into account high stress, etc. Improve convenience and practicability, improve scientificity and rigor, and avoid the effect of low carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

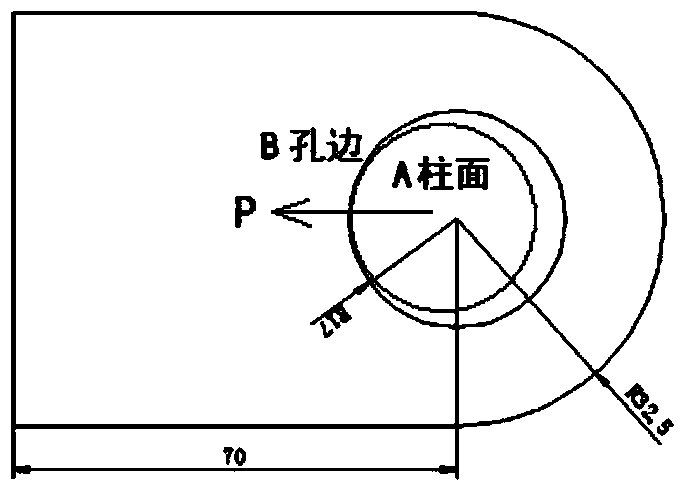

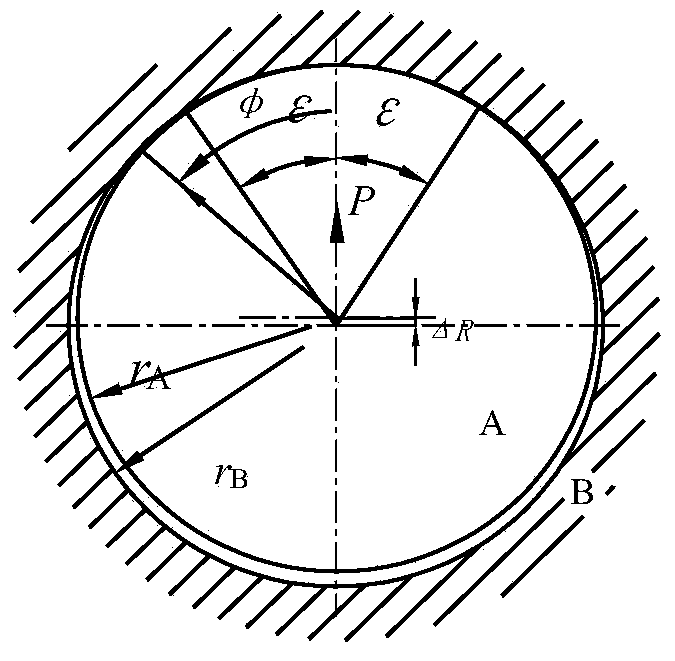

[0037] A design method for improving the load-carrying capacity of the shaft-hole connection structure of the present invention has the core idea of optimizing the design idea, which simplifies the actual model of the shaft-hole connection structure into a plane strain model. By changing the surface shape of the hole edge contact surface and optimizing the surface parameters, the purpose of improving the stress distribution in the shaft hole contact area is achieved. The present invention takes the connection structure of the bolt shaft and the lug hole as an example, and uses the method of the present invention to obtain an optimal connection design.

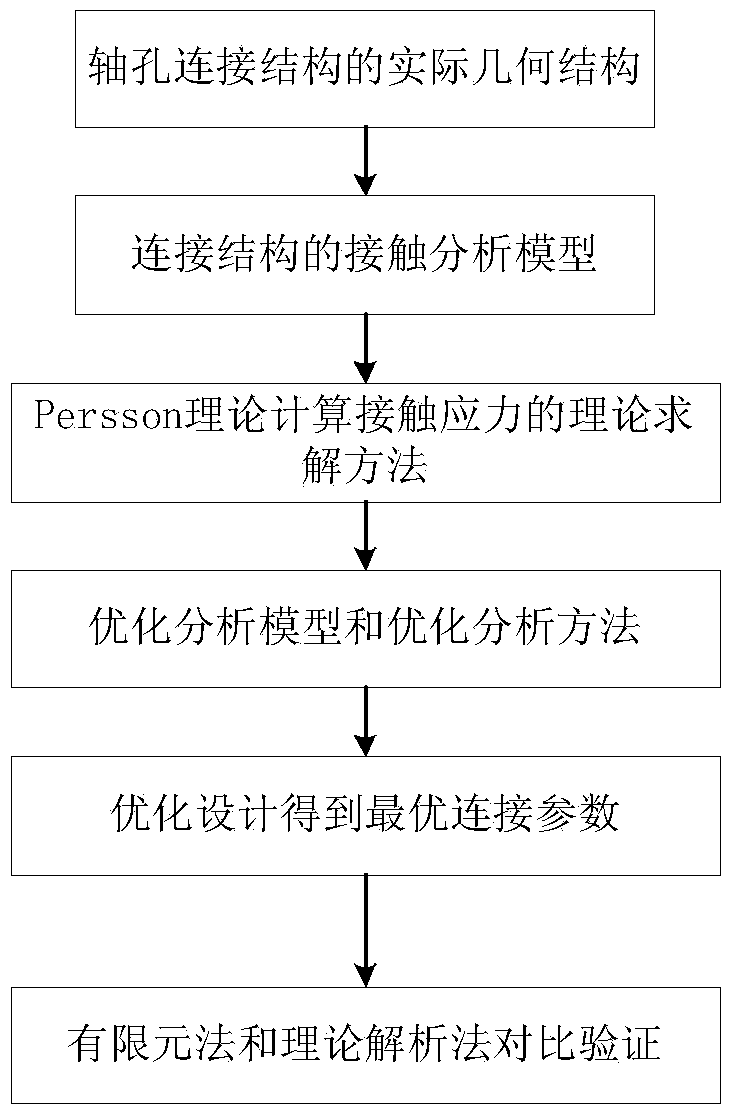

[0038] The invention is a design method for improving the bearing capacity of the shaft-hole connection structure, the flow chart is as follows figure 1 shown, including the following steps:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com