Catalytic wet oxidation treatment method of organic wastewater

A technology of organic wastewater and treatment method, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of metal loss and high COD removal capacity, and achieve reduced emissions, high COD removal effect, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Preparation of Catalyst A1 (Fe-Ce / AC)

[0021] The diameter is 2.0mm, the specific surface area is 704m 2 / g, pore volume 0.7cm 3 / g, commercial columnar activated carbon strips with an average pore size of 2.0 nm were dried at 120 °C for later use. Weigh 500g of dried activated carbon strips, and use Fe(NO 3 ) 3 9H 2 O and Ce(NO 3 ) 3 ·6H 2 O by Fe 2 o 3 and CeO 2 Accounting for 6% and 2% of the total weight of the catalyst respectively, they were prepared into solutions. Impregnate activated carbon strips with an equal volume of Fe-Ce solution for 2 hours, dry at 80°C, and bake at 550°C for 4 hours in a nitrogen atmosphere. After the temperature dropped to room temperature, take it out to obtain catalyst A1.

[0022] Preparation of Catalyst A2 (Fe-Mn-Ce / Al 2 o 3 )

[0023] The macroporous alumina powder and peptizer are kneaded, rolled, and extruded to make a clover-shaped carrier with a diameter of 2.5 mm, and then calcined at 550 ° C in the air to obta...

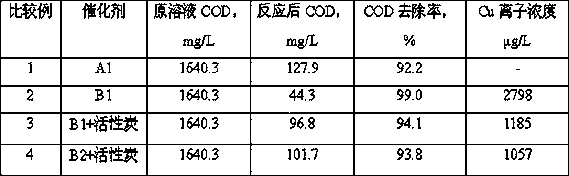

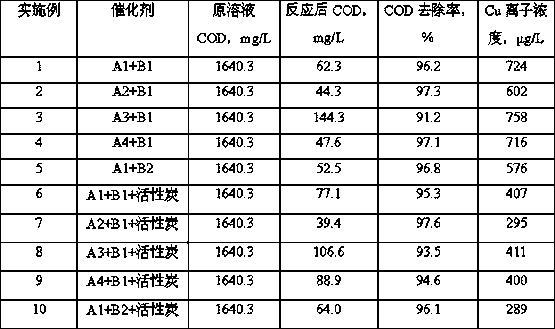

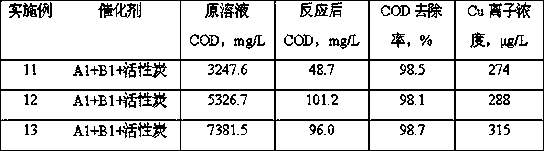

Embodiment 1

[0034] The catalysts A1 and B1 are loaded into the cylindrical reactor according to the volume percentage of 60% and 40% respectively, and the total volume of the catalyst is 100cm 3 . The initial COD value of acid scarlet simulated dye wastewater was 1640.3 mg / L, and oxygen was used as the oxidant, and the dosage was 1.6 times the required theoretical value. The temperature of the reactor is 240°C, the pressure is 3.8 MPa, and the residence time is 60 minutes. After the reaction, the COD of the liquid is tested, and the catalyst activity is measured according to the removal rate of COD. After the reaction, the content of copper ions in the liquid was tested by inductively coupled plasma mass spectrometry (ICP-MS) to investigate the loss of metals. The results are listed in Table 1.

Embodiment 2

[0036] Catalysts A2 and B1 were loaded into the reactor according to volume percentages of 60% and 40% respectively, and the reaction conditions were the same as in Example 1. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com