Preparation method of formaldehyde decomposition type heating radiator coating material with high absorption rate

A formaldehyde decomposition and coating material technology, applied in the field of coatings, can solve problems such as formaldehyde pollution, achieve excellent adsorption performance, promote single atom dispersion, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

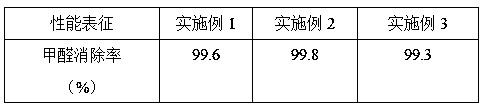

Examples

Embodiment Construction

[0024]In terms of parts by weight, weigh 45 to 50 parts of 98% sulfuric acid by mass fraction, 3 to 5 parts of 200 mesh expanded graphite powder and 6 to 8 parts of potassium permanganate in a beaker, stir and mix them and place them at 0 to 5 ℃ for 20-30 minutes in a water bath to obtain the reaction solution and raise the temperature to 35-40 ℃. After the heat preservation reaction for 1-2 hours, the heated reaction solution was collected and counted in parts by weight. Weighed 45-50 parts of deionized water, 15 ~20 parts of 10% hydrogen peroxide solution by mass fraction and 15~20 parts of heating reaction solution are placed in an Erlenmeyer flask, stirred and mixed, and placed at 45~50°C for 25~30min, and after standing for 20~24h, filter and Collect the lower precipitate, wash the lower precipitate with water until the washing solution is neutral, and then dry at 55-65°C for 6-8 hours to obtain dry graphite oxide particles; weigh 45-50 parts by weight Deionized water, 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com