A kind of intumescent halogen-free flame-retardant EVA-based composite material and preparation method thereof

A composite material and intumescent technology, which is applied in the field of intumescent halogen-free flame-retardant EVA-based composite materials and its preparation, can solve the problems of flame-retardant efficiency or environmental protection requirements that cannot meet the performance requirements of new flame-retardant composite materials, and achieve particle size The effect of small diameter, improved flame retardant performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

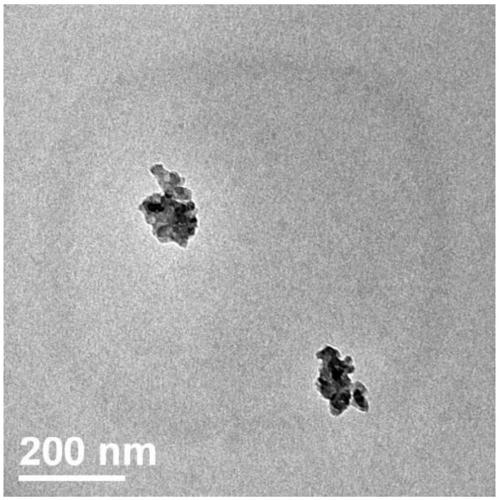

[0022] Weigh 50g of EVA pellets, 12.5g of starch, 35.5g of ammonium polyphosphate, and 2g of nitrogen-based trimethylene zirconium phosphate. After mixing the above pellets evenly, at a temperature of 195°C and a screw speed of 25r / min, the Twin-screw extruder melts and blends in melting, makes the EVA-based composite material of the present invention, and its electron microscope figure is as follows: figure 1 As shown, the particle size of the prepared product is smaller, which is nanometer size. After testing, the limiting oxygen index is 28.5%, the UL-94 test reaches V-0 level, and there is no droplet phenomenon. The tensile strength of the composite is 9.17 MPa, and the elongation at break is 115.6%.

Embodiment 2

[0024] Weigh 50g of EVA pellets, 12.5g of starch, 34.5g of ammonium polyphosphate, and 3g of zirconium nitrogen trimethylene phosphate. After mixing the above pellets evenly, at a temperature of 195°C and a screw speed of 25r / min, Melt-in-melt blending in a twin-screw extruder to prepare the EVA-based composite material of the present invention. After testing, the limiting oxygen index is 30.0%, and the UL-94 test reaches V-0 level, and there is no droplet phenomenon. The tensile strength of the composite is 10.29 MPa, and the elongation at break is 104.9%.

Embodiment 3

[0026] Weigh 50g of EVA pellets, 12.5g of starch, 33.5g of ammonium polyphosphate, and 3g of zirconium nitrogen trimethylene phosphate. After mixing the above pellets evenly, at a temperature of 195°C and a screw speed of 25r / min, the Melt-in-melt blending in a twin-screw extruder to prepare the EVA-based composite material of the present invention. After testing, the limiting oxygen index is 31.0%, the UL-94 test reaches V-0 level, and there is no droplet phenomenon. The tensile strength of the composite is 9.54 MPa, and the elongation at break is 101.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com