Garbage incinerator system and garbage incineration flue gas purification hearth catalytic removal method

A garbage incinerator and garbage technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of high input cost, large equipment volume, limited removal efficiency of harmful gases and carcinogens, etc., and reduce environmental hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

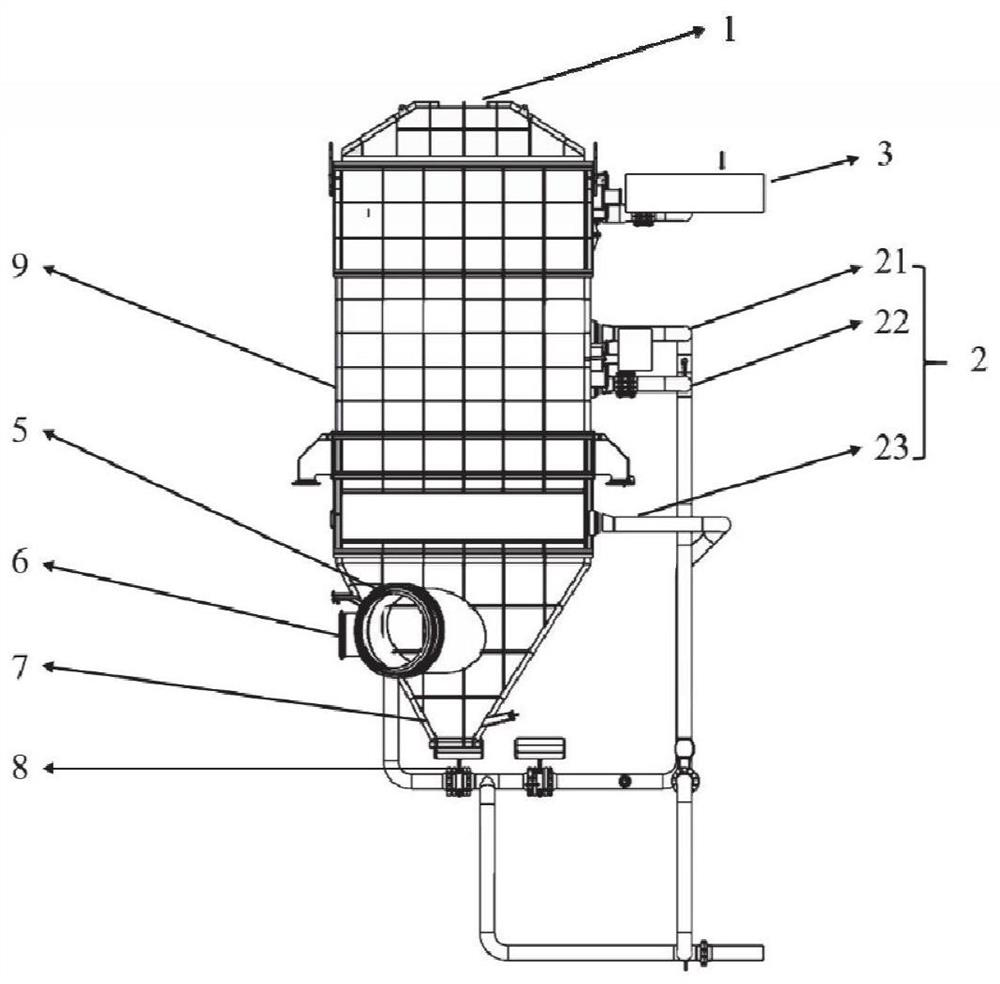

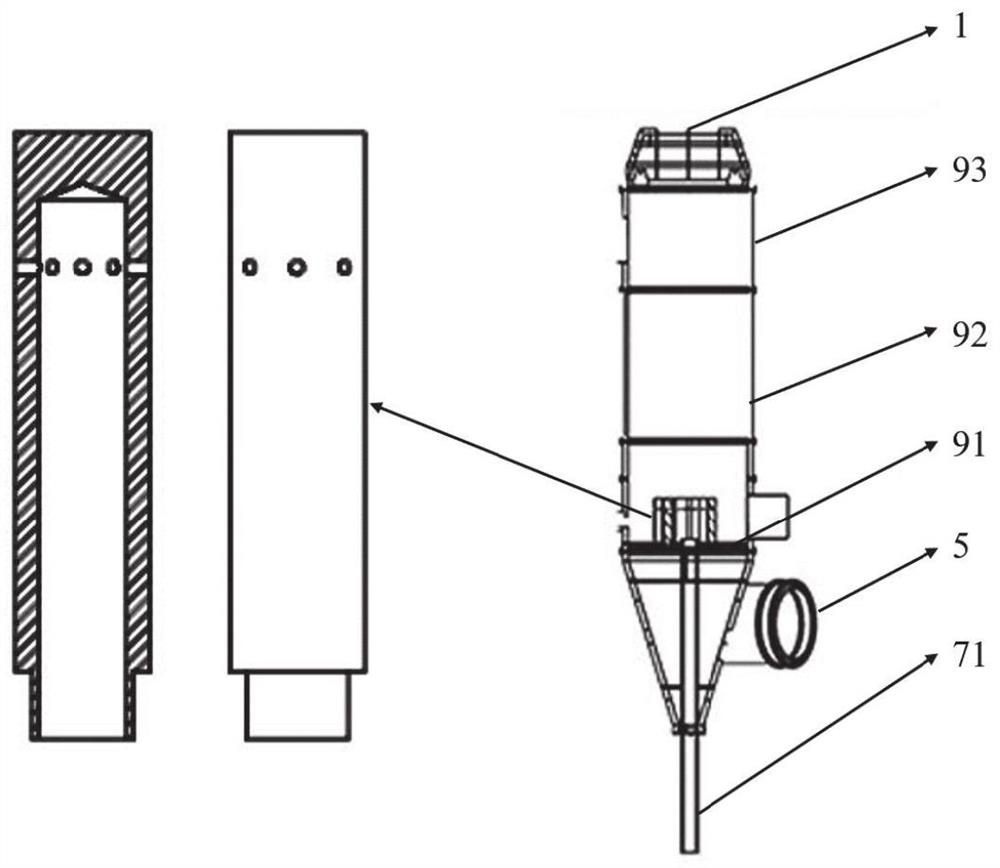

[0084] A waste incinerator system such as Figure 1~3 As shown, it includes: furnace outlet 1, chimney 2, tertiary tuyere 21, secondary tuyere 22, primary tuyere 21, hood baffle 3, peripheral steel frame structure 4, air inlet 5, material inlet 6, equal pressure air chamber 7 , cold slag pipe 71, slag drop port 8, furnace main body 9, chlorine inhibitor 91 in the boiling vertical section, catalytic refractory material 92 in the boiling section, and catalytic refractory material 93 in the suspension section.

[0085] The catalytic refractory material 93 in the top suspension section can replace the original furnace wall refractory material in the suspension section with the top furnace wall refractory material. In actual operation, it can combine the original CO of the flue gas to reduce the NO x Catalyzed removal.

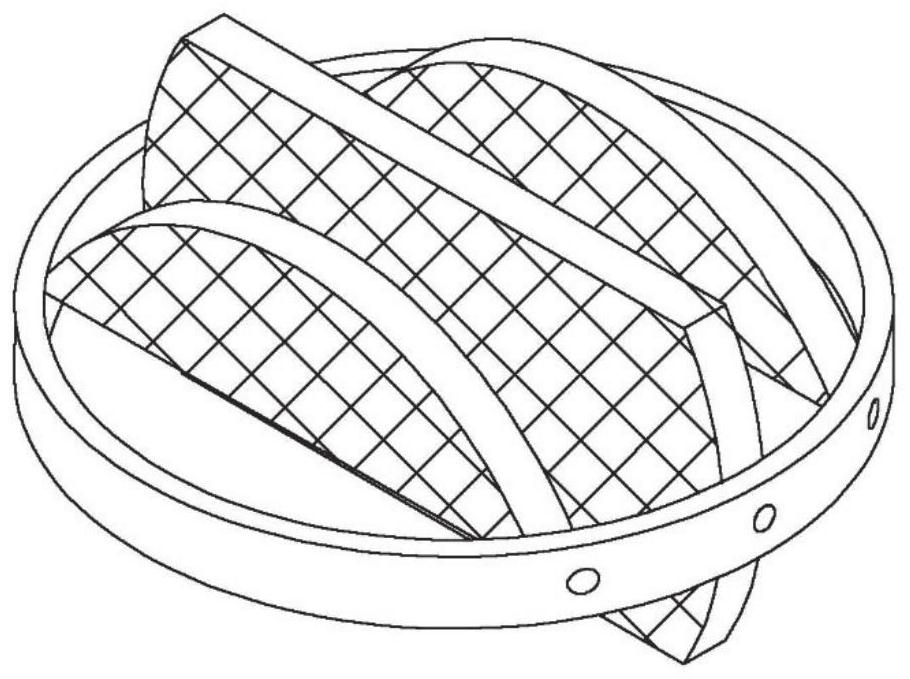

[0086] The boiling section catalytic refractory material 92 replaces the original boiling section furnace wall, air distribution plate 3 and surface refractory ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com