Storage element, developing cartridge employing same and image forming equipment

A technology for storage elements and developing cartridges, which is applied in the fields of electric recording process equipment using charge patterns, electric recording technology using charge patterns, and electric recording techniques, etc., which can solve the problem of affecting the stability of storage elements and affecting the components on the storage elements. Lifespan, damaged components and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

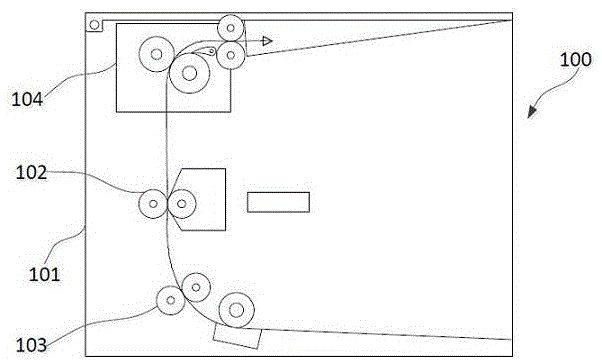

[0060] figure 2 Shown is a schematic diagram of the overall structure of an imaging device provided in this embodiment. The image forming apparatus 100 includes an image forming apparatus main body 101 , a developing cartridge 102 , a paper feed roller 103 and a fixing assembly 104 . Among them, the developing cartridge 102 is used to form an image and transfer the image to a recording medium. The developing cartridge 102 is detachably installed in the imaging device, and a storage element is installed on the developing cartridge for recording the developing cartridge information and imaging control parameters. The main body of the imaging device 101 communicates with the developing cartridge by electrically connecting with the storage element on the developing cartridge 102 , for example, reading the information and control parameters of the developing cartridge in the storage element, or writing the usage information of the developing cartridge into the storage element. T...

Embodiment 2

[0076] Such as Figure 7 As shown, the storage element 600 in this embodiment includes a storage element substrate 610, and a positioning notch 620 for positioning and a plurality of contacts are provided on the storage element substrate 610 . Different from Embodiment 1, the plurality of contacts on the storage element substrate in this embodiment are arranged in a row parallel to the axis of the photosensitive drum, and the plurality of contacts in this embodiment include GND contact 611, VCC contact Point 612 , signal contact 613 and signal contact 614 . The number of signal contacts provided by this embodiment is not limited to Figure 7 Two of them can also be set to 1 or more than 2.

[0077] Such as Figure 8 Shown is a schematic diagram of the contact arrangement method of the storage element in this embodiment. The height of the contact portion of the GND contact 711 is higher than that of other contacts, and the height of the contact portion of the VCC contact 71...

Embodiment 3

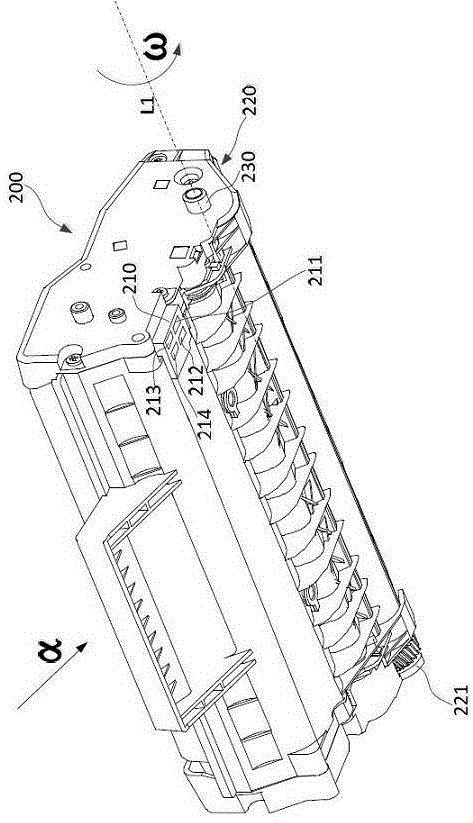

[0083] Figure 9 It is a partial schematic diagram of the main body of the imaging device in this embodiment. As shown in the figure, a straight line L3 in the figure indicates the axis of the photosensitive drum as a rotating member in the developing cartridge when the developing cartridge is installed in the image forming apparatus. The rotating element is not limited to the photosensitive drum, and in other embodiments may also be elements such as developing rollers or protrusions provided at both ends of the developing cartridge. The X2, Y2, and Z2 directions in the figure represent three axial directions in which the main body of the imaging device is located in a Cartesian coordinate system, respectively.

[0084] The main body 800 of the image forming apparatus is provided with a plurality of contact pieces contacting with the storage element of the developing cartridge, and the plurality of contact pieces are arranged in two rows. The contact element may be a conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com