Hydrodesulfurization catalyst grading method

A hydrodesulfurization and catalyst technology, which is applied in refining to remove heteroatoms, etc., can solve the problems of increasing the catalyst loading weight, and achieve the effects of better accommodating mechanical impurities, improving loading ratio, and better material distribution performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this example, the top of the reactor is a catalyst bed with a low bulk ratio, accounting for 10% of the volume of the entire reactor. The ratio of large-diameter catalyst to small-diameter catalyst in the bed is 10:1 by weight, and the packing ratio is 0.993g / cm 3 , the calculated bed porosity is 33.8%.

[0025] The lower part of the reactor is a high heap ratio catalyst bed, accounting for 90% of the entire reactor volume. The ratio of large-diameter catalyst to small-diameter catalyst in the bed is 2:1 by weight, and the packing ratio is 1.042g / cm 3 , the calculated bed porosity is 30.5%.

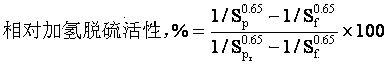

[0026] The activity evaluation of the catalyst loaded in this example was carried out, and the evaluation results were compared with the evaluation results of the FHUDS-6 catalyst with a diameter of only 2.3 mm (see Comparative Example 1). Based on the hydrodesulfurization activity after 48 hours of operation in Comparative Example 1 as 100%, the relative hydrodesulfurization...

Embodiment 2

[0028] In this example, the top of the reactor is a catalyst bed with a low bulk ratio, accounting for 20% of the volume of the entire reactor. The ratio of large-diameter catalyst to small-diameter catalyst in the bed is 5:1 by weight, and the packing ratio is 1.007g / cm 3 , the calculated bed porosity is 32.9%.

[0029] The lower part of the reactor is a high heap ratio catalyst bed, accounting for 80% of the entire reactor volume. The ratio of large-diameter catalyst to small-diameter catalyst in the bed is 1:1.5 by weight, and the packing ratio is 1.035g / cm 3 , the calculated bed porosity is 31.0%.

[0030] The activity evaluation of the catalyst loaded in this example was carried out, and the evaluation results were compared with the evaluation results of the FHUDS-6 catalyst with a diameter of only 2.3 mm (see Comparative Example 1). Based on the hydrodesulfurization activity after 48 hours of operation in Comparative Example 1 as 100%, the relative hydrodesulfurizatio...

Embodiment 3

[0032] In this example, the top of the reactor is a catalyst bed with a low stack ratio, accounting for 25% of the total reactor volume. The ratio of large-diameter catalyst to small-diameter catalyst in the bed is 4:1 by weight, and the packing ratio is 1.012g / cm 3 , the calculated bed porosity is 32.5%.

[0033] The lower part of the reactor is a high heap ratio catalyst bed, accounting for 75% of the entire reactor volume. The ratio of large-diameter catalyst to small-diameter catalyst in the bed is 1:2 by weight, and the packing ratio is 1.020g / cm 3 , the calculated bed porosity is 32.0%.

[0034]The activity evaluation of the catalyst loaded in this example was carried out, and the evaluation results were compared with the evaluation results of the FHUDS-6 catalyst with a diameter of only 2.3 mm (see Comparative Example 1). Based on the hydrodesulfurization activity after 48 hours of operation in Comparative Example 1 as 100%, the relative hydrodesulfurization activity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com