Method for fabricating microlens array beam shaper by femtosecond laser enhanced chemical etching

A microlens array and femtosecond laser technology, applied in the field of femtosecond laser Wiener processing and laser optics, can solve the problem of difficult to achieve high filling ratio microlens array processing, not suitable for batch preparation of large-area microlens arrays, long-term response etc. to achieve high-efficiency beam shaping, good surface morphology, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific implementation steps of this embodiment are as follows:

[0028] Step 1. Select quartz glass as the sample material, and the size of the quartz glass sample is 15×15×2mm 3 ;

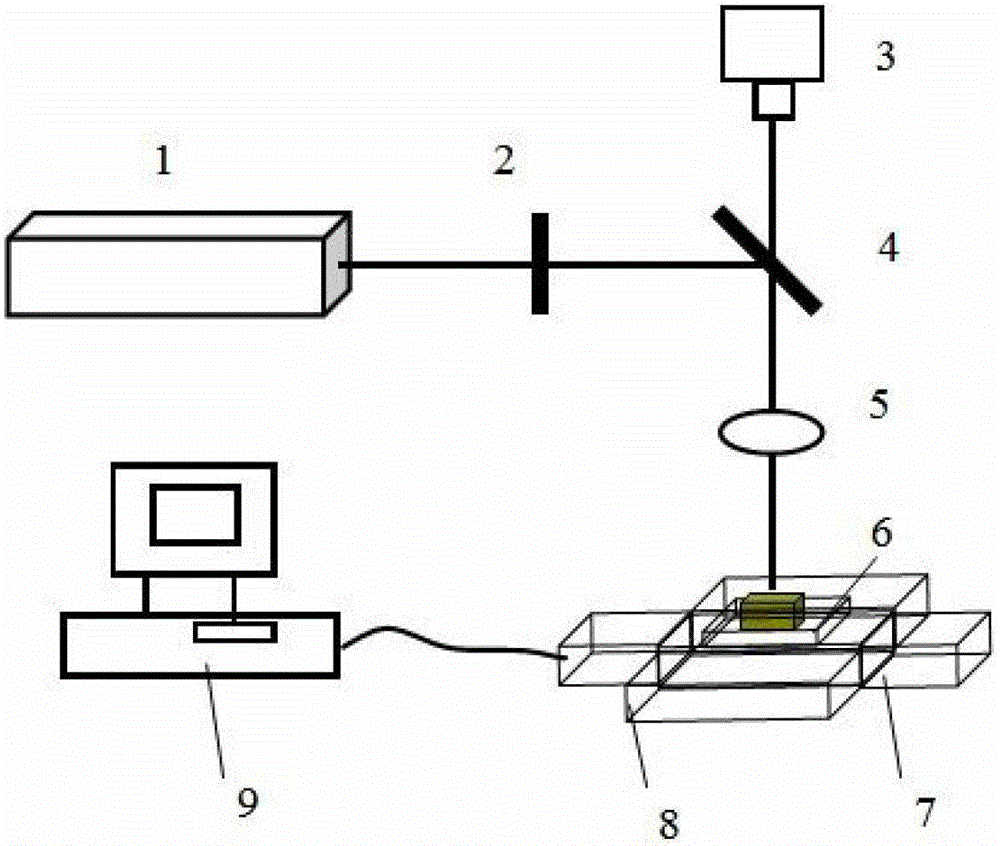

[0029] Step 2. Select an ultrashort pulse laser with a pulse width of 30 fs and a wavelength of 800 nm, focus it on the surface of a quartz glass sample fixed on a three-dimensional precision mobile platform through a microscopic objective lens, and the numerical aperture of the microscopic objective lens is 0.5;

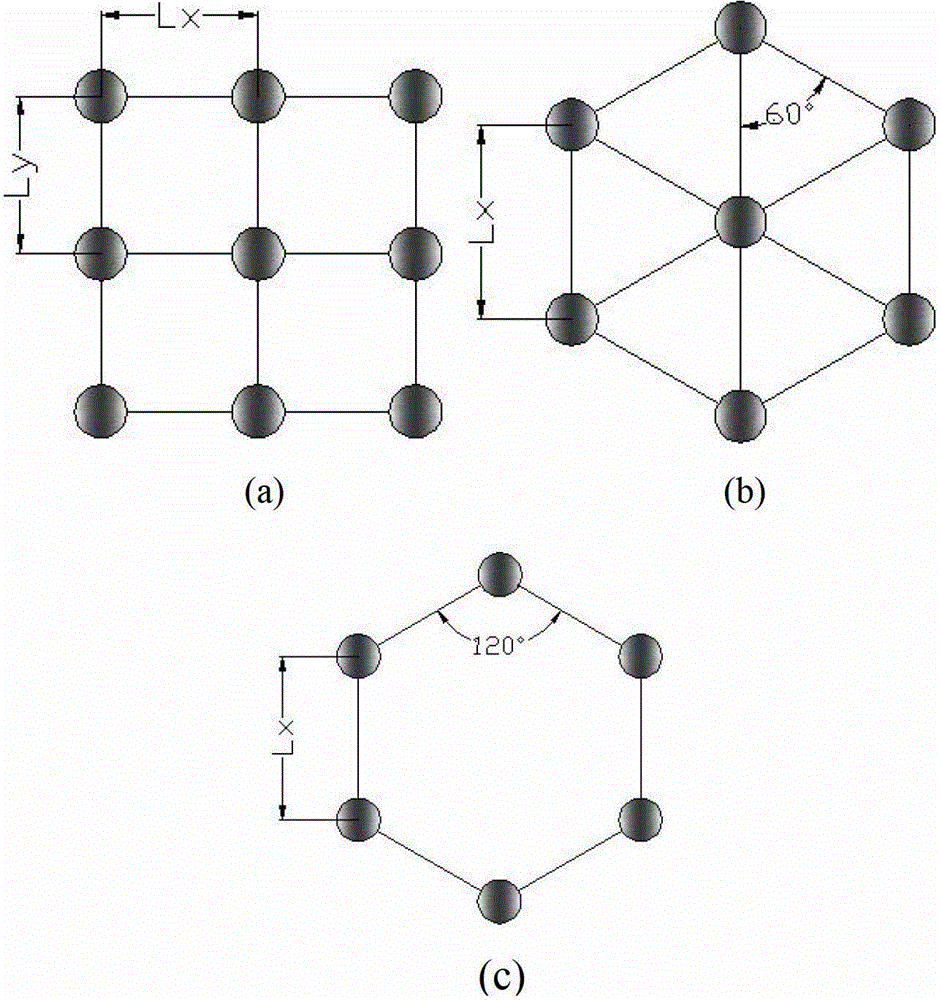

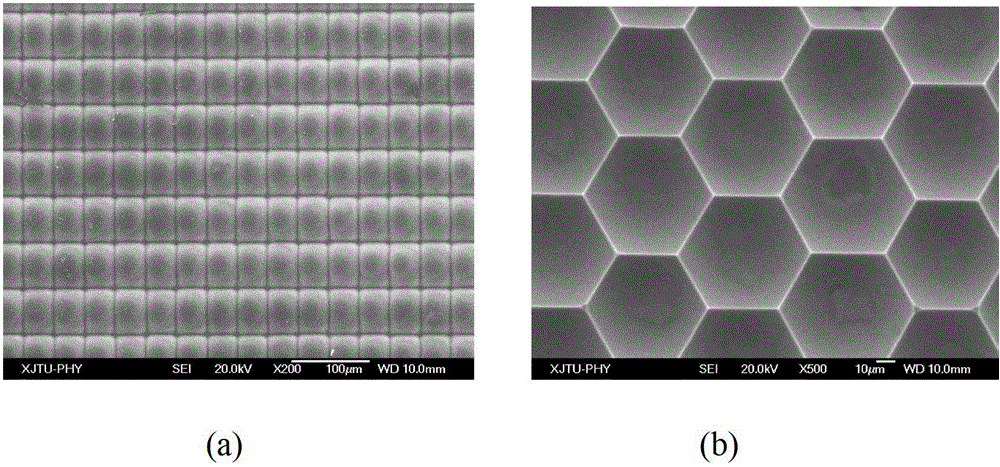

[0030] Step three, refer to figure 2 a, Adjust the arrangement of the pulse action points according to the desired microlens array shape. The moving speed of the three-dimensional precision mobile platform is 3000um / s, and the arrangement of the pulse action points is a rectangle. The black solid circles represent the pulse action points. The distance between adjacent pulse action points is as follows figure 2 Shown in a are L x =40um,L y =60um, control femtosecond l...

Embodiment 2

[0034] The specific implementation steps of this embodiment are as follows:

[0035] Step 1. Select quartz glass as the sample material, and the size of the quartz glass sample is 15×15×1mm 3 ;

[0036] Step 2. Select an ultrashort pulse laser with a pulse width of 50 fs and a wavelength of 800 nm, focus it on the surface of a quartz glass sample fixed on a three-dimensional precision mobile platform through a microscopic objective lens, and the numerical aperture of the microscopic objective lens is 0.5;

[0037] Step three, refer to figure 2 b. Adjust the arrangement of the pulse action points according to the desired microlens array shape. The moving speed of the three-dimensional precision mobile platform is 4000um / s, and the arrangement of the pulse action points is a triangle. The black solid circles represent the pulse action points. The distance between adjacent pulse action points is as follows figure 2 Shown as L in b x =60um, control femtosecond laser single p...

Embodiment 3

[0041] The specific implementation steps of this embodiment are as follows:

[0042] Step 1. Select quartz glass as the sample material; the size of the quartz glass sample is 15×15×1mm 3 ;

[0043] Step 2. Select an ultrashort pulse laser with a pulse width of 50 fs and a wavelength of 800 nm, focus it on the surface of a quartz glass sample fixed on a three-dimensional precision mobile platform through a microscopic objective lens, and the numerical aperture of the microscopic objective lens is 0.4;

[0044] Step three, refer to figure 2 c. Adjust the arrangement of the pulse action points according to the desired microlens array shape. The moving speed of the three-dimensional precision mobile platform is 4000um / s, and the arrangement of the pulse action points is hexagonal. The black solid circle represents the pulse action point , the distance between adjacent pulse action points is as follows figure 2 Shown as L in c x =60um, control femtosecond laser single pulse en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com