High-performance masterbatch with high loading calcium carbonate and preparation method for masterbatch

A calcium carbonate, high-performance technology, applied in the industrial chemical field, can solve the problems of high mechanical properties and high dispersion of fillers, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

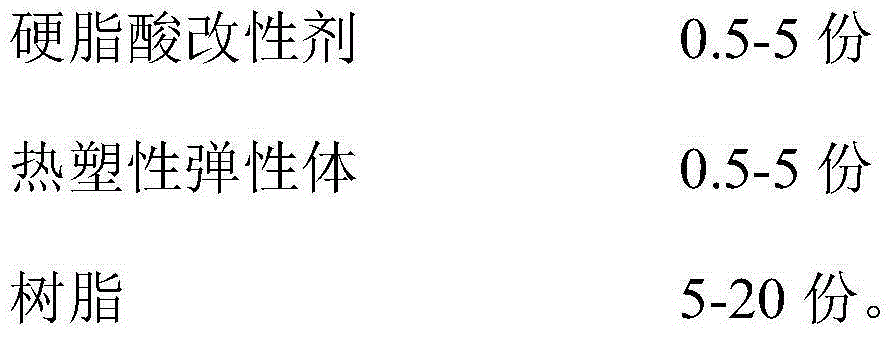

[0024] The present embodiment provides a high-performance high-filling calcium carbonate masterbatch, which is prepared from the following components by weight:

[0025]

[0026] The coupling agent is composed of 0.25 parts by weight of glyceryl caprylate polyoxyethylene ether and 0.25 parts of rare earth stearate.

[0027] Preparation process: weigh calcium carbonate, fully dry in a desiccator to remove water, make the water content less than 0.1%, and crush through 800-2500 mesh sieve. Weigh calcium carbonate and additives into a high-speed mixer, stir for 8 minutes at a speed of 300-400r / min, and a temperature of 120°C; weigh stearic acid rare earth coupling agent and put it into the mixture, stir for 8 minutes at a speed of The temperature is 300-400r / min, and the temperature is 120°C; Weigh the thermoplastic elastomer, resin and the mixture obtained from the above steps and put it into the internal mixer, and banbury for 15 minutes at the temperature of 160°C; then pla...

Embodiment 2

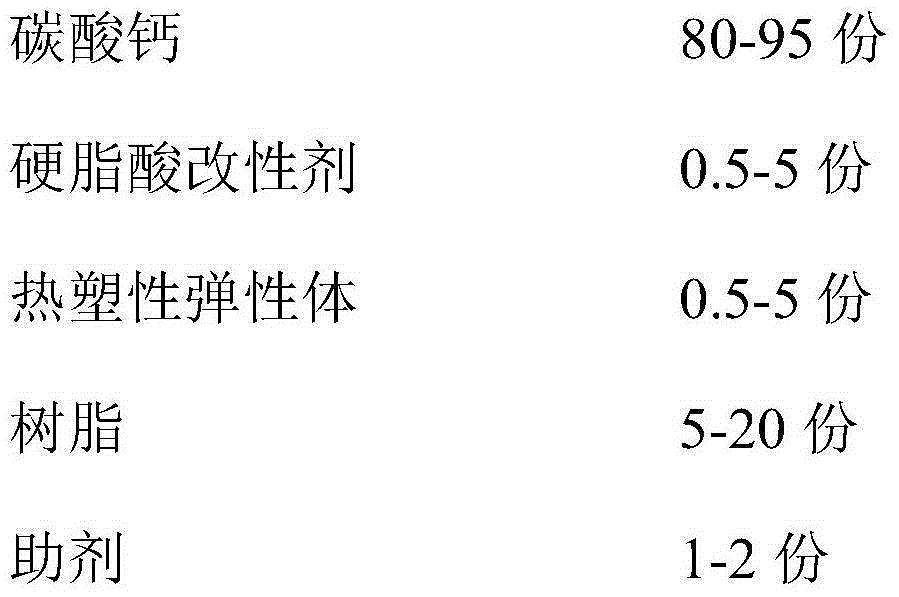

[0029] The present embodiment provides a high-performance high-filling calcium carbonate masterbatch, which is prepared from the following components by weight:

[0030]

[0031] The coupling agent is composed of 0.25 parts by weight of glyceryl caprylate polyoxyethylene ether and 0.25 parts of rare earth stearate.

[0032] Preparation process: weigh calcium carbonate, fully dry in a desiccator to remove water, make the water content less than 0.1%, and crush through 800-2500 mesh sieve. Weigh calcium carbonate and additives into a high-speed mixer, stir for 12 minutes at a speed of 300-400r / min, and a temperature of 100°C; weigh stearic acid rare earth coupling agent and put it into the mixture, stir for 12 minutes at a speed of The temperature is 300-400r / min, and the temperature is 100°C; Weigh the thermoplastic elastomer, resin and the mixture obtained from the above steps, put it into the internal mixer, and banbury for 30 minutes at the temperature of 180°C; then put ...

Embodiment 3

[0034] The present embodiment provides a high-performance high-filling calcium carbonate masterbatch, which is prepared from the following components by weight:

[0035]

[0036] The coupling agent is composed of 0.25 parts by weight of glyceryl caprylate polyoxyethylene ether and 0.25 parts of rare earth stearate.

[0037] Preparation process: weigh calcium carbonate, fully dry in a desiccator to remove water, make the water content less than 0.1%, and crush through 800-2500 mesh sieve. Weigh calcium carbonate and additives into a high-speed mixer, stir for 10 minutes at a speed of 300-400r / min, and a temperature of 110°C; weigh stearic acid rare earth coupling agent and put it into the mixture, stir for 10 minutes at a speed of The temperature is 300-400r / min, and the temperature is 110°C; weigh the thermoplastic elastomer, resin and the mixture obtained from the above steps, put it into the internal mixer, and banbury for 20 minutes at a temperature of 170°C; then put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com