Charging supporting structure

A technology of supporting structure and charging, which is applied in the directions of jet propulsion, rocket engine, machine/engine, etc., can solve the problems of affecting the charging profile of the front-end combustion chamber, performance deviating from the design value, damage to the interlayer structure, etc. To achieve the effect of charging stability, beneficial to the overall design, and effective charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

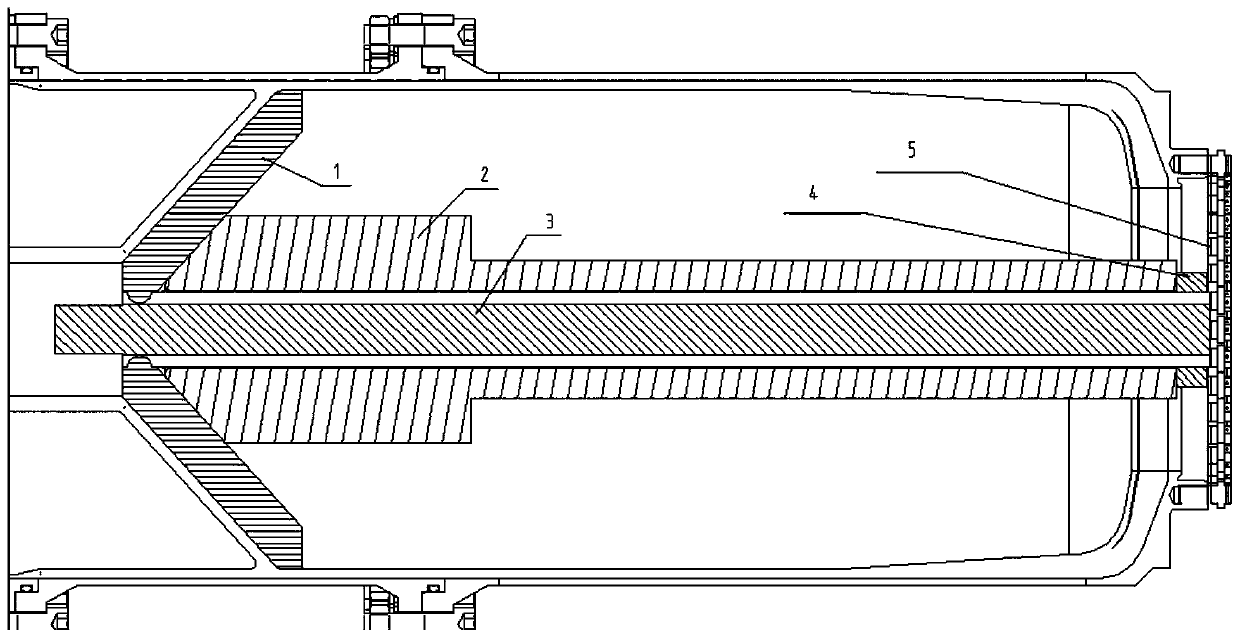

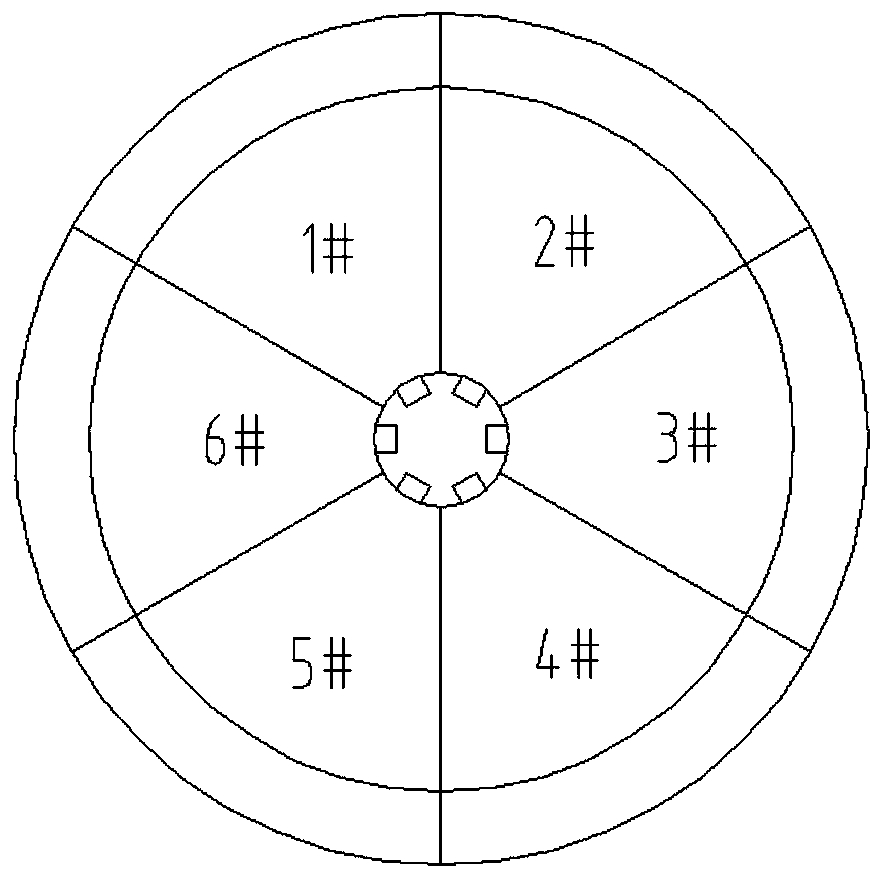

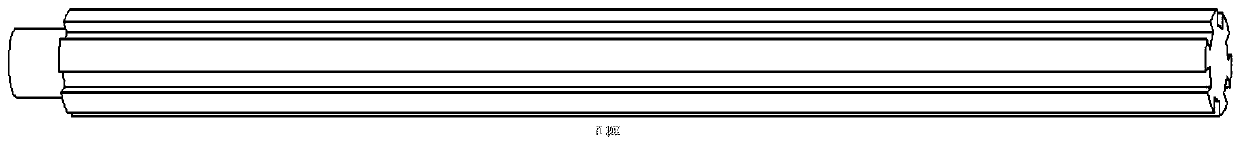

[0031] A charge support structure, including a mandrel 1, a support rod 2, an inner cylinder 3, a fastening device 4, and a support plate 5;

[0032] The mandrel 1 includes a plurality of fan rings, and the plurality of fan rings form a ring shape, the mandrel 1 is used to support the soft compartment of the external engine; the support rod 2 is used to support the mandrel 1; The inner cylinder 3 is used for positioning and guiding the mandrel 1 after being connected with the external structure; the fastening device 4 is used for connecting the support rod 2 and the inner cylinder 3; the support plate 5 is connected with the external engine After the head end is connected, support force is provided to the inner cylinder 3 and the support rod 2 at the same time.

[0033] The surface of the inner cylinder 3 is provided with a guide groove, and each of the fan rings is provided with a slide groove, and the guide groove is matched with the slide groove.

[0034] The cross-section...

Embodiment 2

[0044] A charge support structure, the main technical proposal is: the charge support structure includes a mandrel 1, an inner cylinder 3, a support rod 2, a support plate 5, and a fastening device 4. In this embodiment, the fastening device 4 adopts a reinforcement nut After the mandrel 1 splits into the designated position through the petal groove (guide groove) of the inner cylinder 3, it is stretched by the support rod 2 to form a tapered whole to support the soft interlayer. The reinforcement nut is fixed, the inner cylinder 3 is fixed by the support plate 5, and the support plate 5 is fastened by screws to realize the initial design state of the compartment when the two-pulse charging is completed; after the front pulse combustion chamber completes the solidification of the charge, remove the support plate 5 and the reinforcement nut, pull out the support rod 2, you can hook out the mandrel 1, then remove the inner cylinder 3, and finally connect the wing column rear rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com