Polymeric marker with high radiopacity

a polymer marker and radiopacity technology, applied in the direction of radiation diagnostic clinical applications, prosthesis, discharge tube/lamp details, etc., can solve the problems of catheter shaft, undesirable discontinuity, and relatively expensive manufacture of metallic markers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

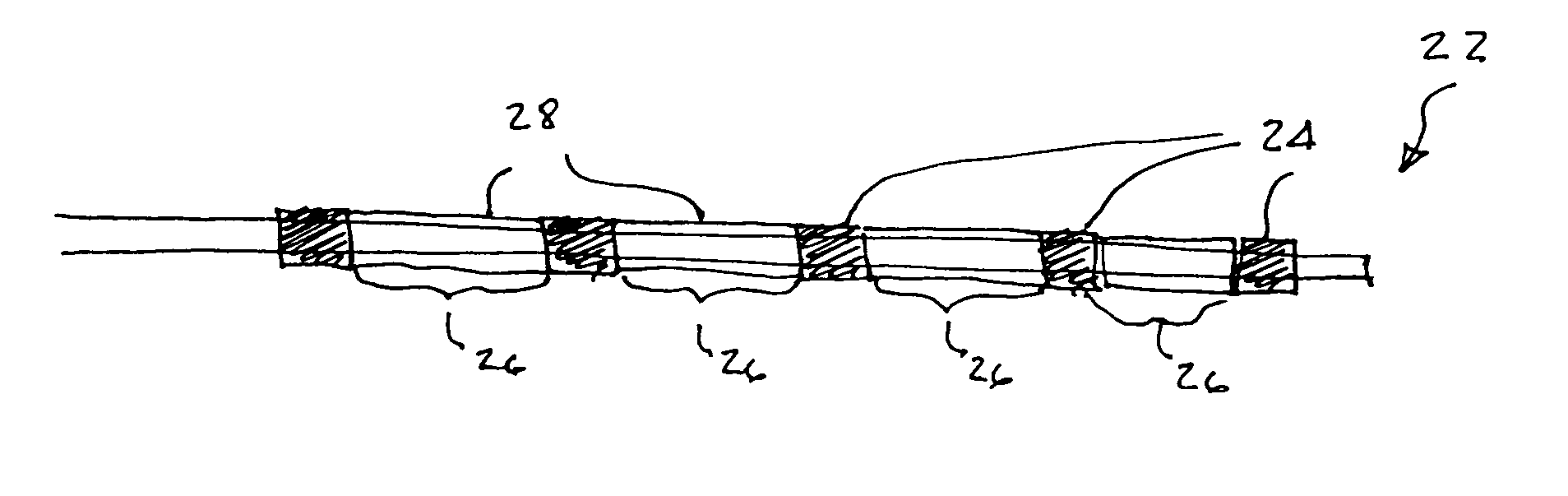

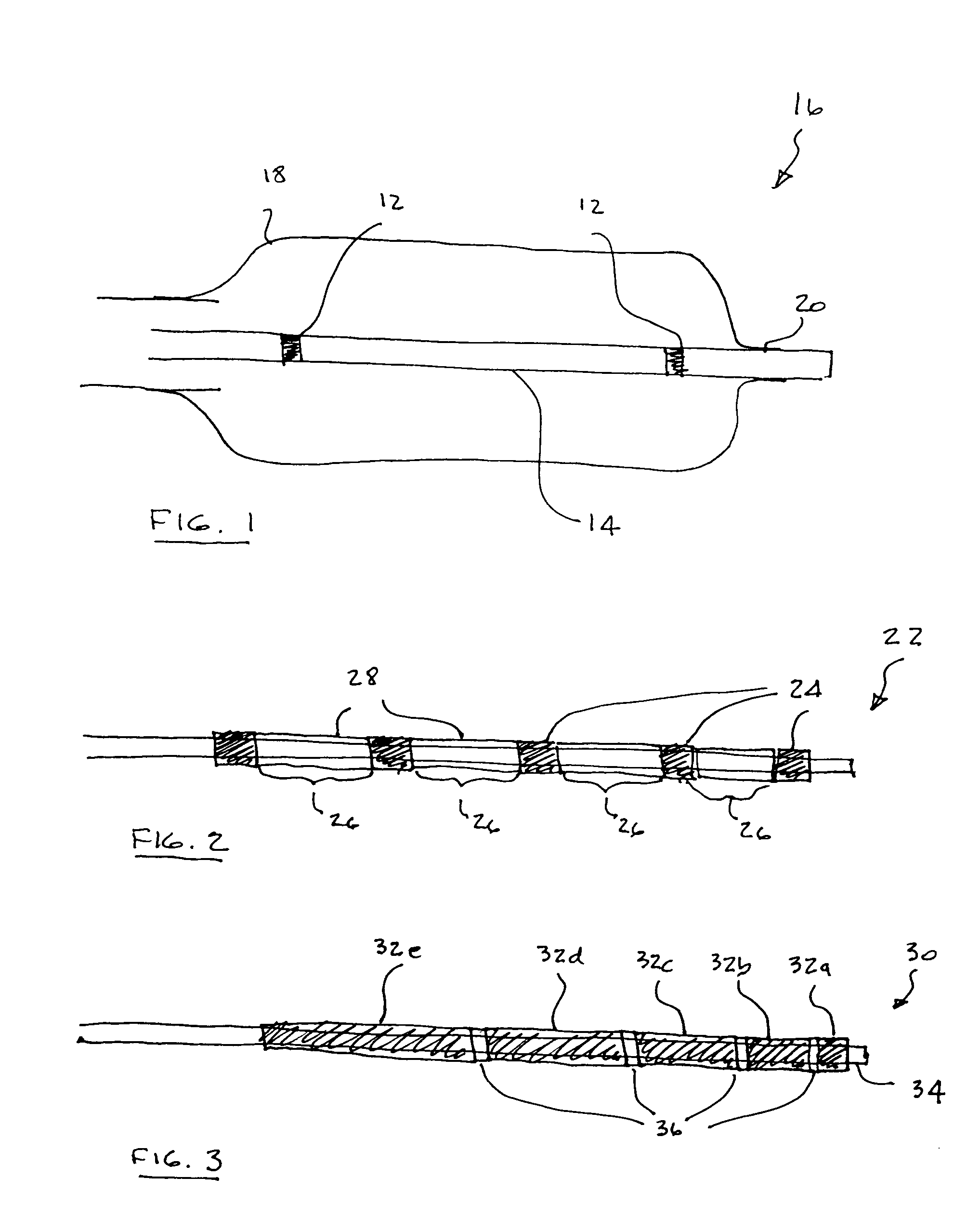

[0017] The present invention provides a radiopaque marker for use on a variety of devices that is flexible, highly radiopaque and is easily attachable to such devices by melt bonding. These properties allow markers to be of minimal thickness and thereby minimize the effect the marker has on the overall profile and stiffness of the device to which it is to be attached.

[0018] In order to achieve the high fill ratios that are necessary to attain the desired radiopacity and in order to do so without compromising the compoundability and workability of the polymeric material nor its ultimate strength and flexibility, a number of different parameters have been found to be of importance. More specifically, both the particle shape and particle size of the radiopaque agent must be carefully controlled while the inclusion of a MA-g-PO in the polymer blend is critical. An antioxidant may additionally be included in an effort to reduce the adverse effect the high processing temperatures and she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com