Preparation method of single-walled carbon nanotube-metal hybrid AlPO4-5 molecular sieve composite membrane

A technology of single-walled carbon nanotubes and molecular sieve membranes, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of low SWCNTs content, long time consumption, high energy consumption, etc., to avoid thermodynamic deformation, increase filling capacity, highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

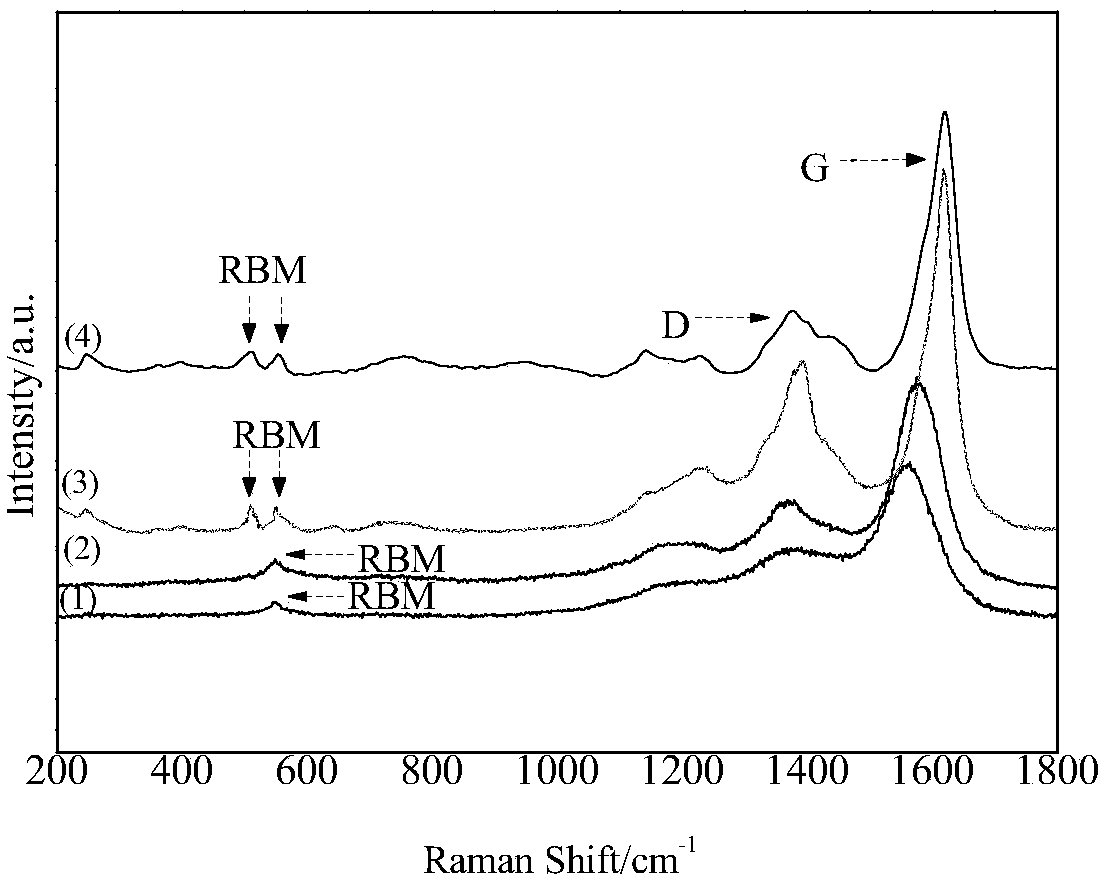

Embodiment 1

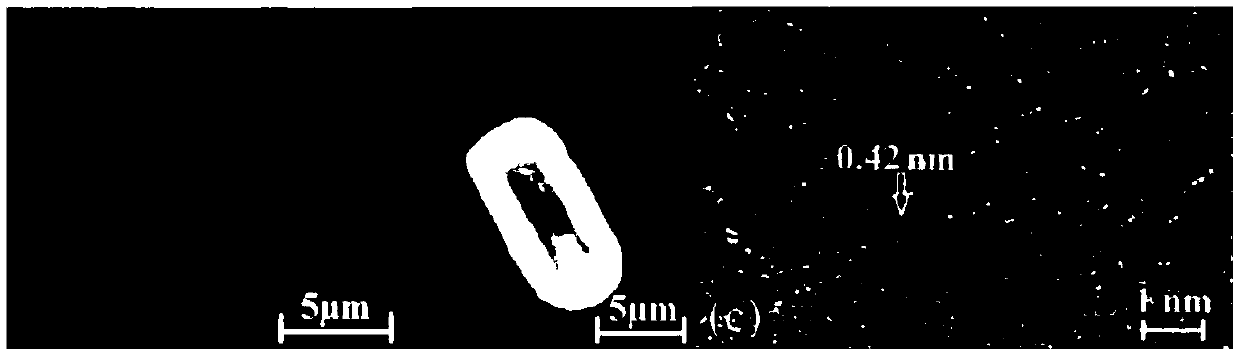

[0032] (1) Preparation of FeAlPO on a porous ceramic support 4 -5 molecular sieve membrane

[0033] According to 1Al 2 o 3 :1.3P 2 o 5 :1TPABr:1000H 2 O:0.3FeCl 3 (mol) ratio of materials to prepare synthetic liquid. Using aluminum isopropoxide as the source of aluminum, in order to fully dissolve it, aluminum isopropoxide is added to phosphoric acid aqueous solution, and stirred and dissolved in an oil bath at 60°C for about 5 hours. The dissolved aluminum isopropoxide aqueous solution is basically transparent liquid. Then FeCl was mixed under stirring 3 Add to the phosphoric acid aqueous solution dissolved in aluminum isopropoxide, and continue to stir until it is completely dissolved. Under stirring state, TPABr was added dropwise into the mixed liquid, and stirred for two hours to completely dissolve each substance, and the pH of the synthetic liquid was adjusted to 6, and then aged at room temperature for 10 hours. Put 20ml of synthesis solution and the sheet-sh...

Embodiment 2

[0039] (1)NiAlPO 4 Preparation of -5 molecular sieve membrane

[0040] Basically the same as Example 1, the difference is that aluminum sulfate is used as the aluminum source, according to 1Al 2 o 3 :0.8P 2 o 5 :0.15TPAOH:45H 2 O:0.075Ni(NO 3 ) 2 (mol) ratio of materials to prepare synthetic liquid. The fully dissolved aluminum sulfate aqueous solution is basically a transparent liquid. Then, the phosphoric acid solution dissolved with a certain amount of nickel nitrate was added dropwise into the aluminum sulfate aqueous solution, and stirred at room temperature until uniform. Under the condition of stirring, TPAOH was gradually added dropwise to the mixed liquid in sequence, and the stirring was continued for 2 hours. After the substances were completely dissolved, the pH of the reaction liquid was adjusted to about 2. The reaction solution was aged at room temperature for 20 hours before being added to the reactor. Then, 30ml of the synthetic solution and the shee...

Embodiment 3

[0047] (1) Preparation of CoAlPO-5 molecular sieve membrane on porous alumina support

[0048] It is basically the same as Example 1, except that sodium aluminate is used as the aluminum source respectively, according to 1Al 2 o 3 :1.3P 2 o 5 :0.5TPABr:200H 2 O:0.15Co(NO 3 ) 3 (mol) ratio of materials to prepare synthetic liquid. The reaction temperature was 180°C, and the reaction time was 100 hours.

[0049] (2) Detection of integrity of CoAlPO-5 molecular sieve membrane

[0050] Concrete operation steps are identical with embodiment 1

[0051] The CoAlPO-5 molecular sieve membrane obtained after two synthesis reactions, its N 2 The air permeability is generally less than 5×10 -11 mole m -2 ·Pa -1 ; It shows that the synthesized tubular CoAlPO-5 molecular sieve membrane has almost no intergranular defects.

[0052] (3) Preparation of single-wall carbon nanotube-CoAlPO-5 molecular sieve composite membrane

[0053] It is basically the same as Example 1, except th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com