Pulse type shock processing on-line compound injection molding method and its equipment

A technology of injection molding and impact strengthening, applied in the field of pulse impact strengthening on-line compounding injection molding method and equipment, can solve the problems of poor melt temperature uniformity, affecting the quality stability of products, etc., to reduce energy consumption of the whole machine, improve Temperature uniformity and dispersion effect, the effect of improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be further described below in conjunction with the drawings and embodiments, but the scope of protection claimed by the present invention is not limited to the scope of the embodiments.

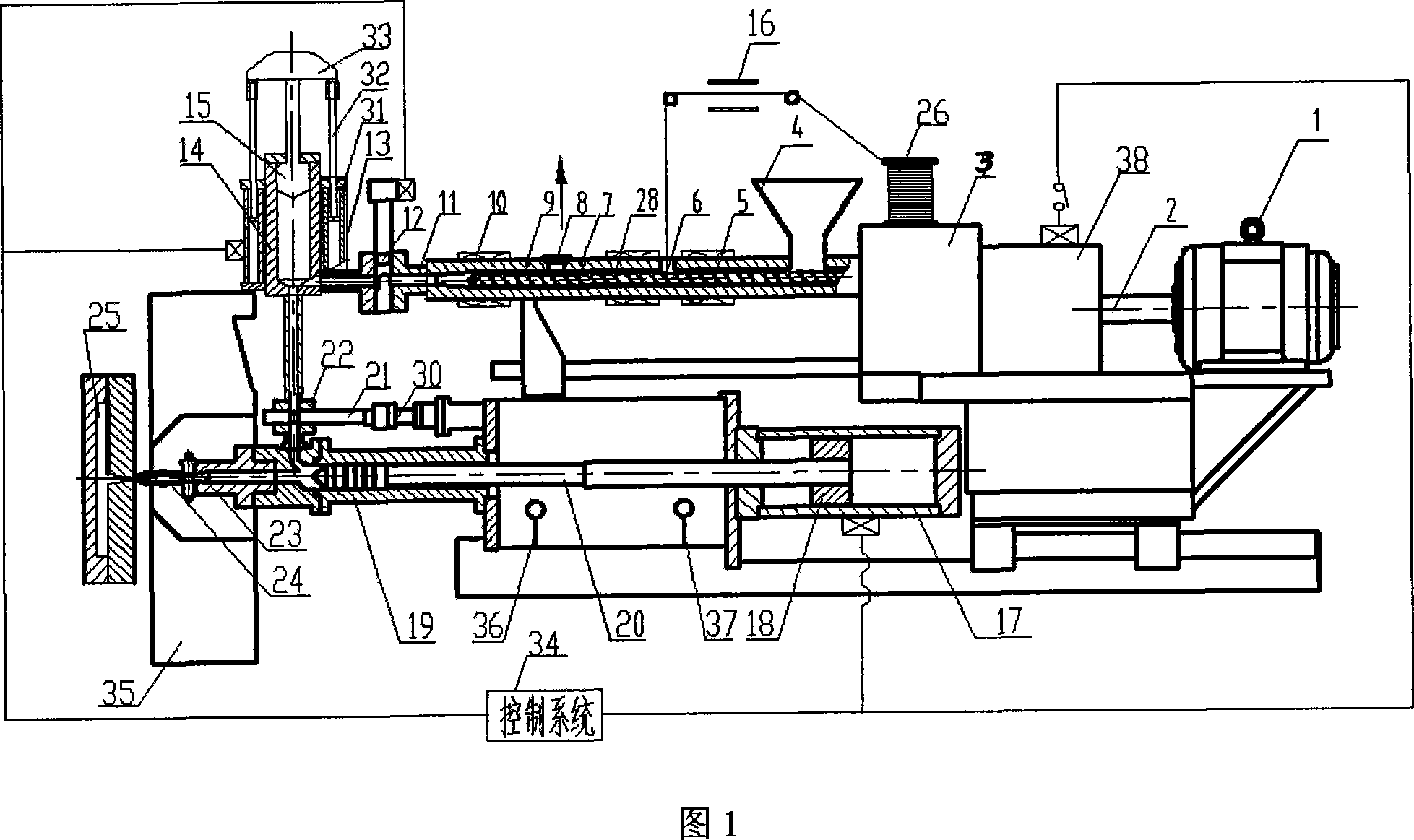

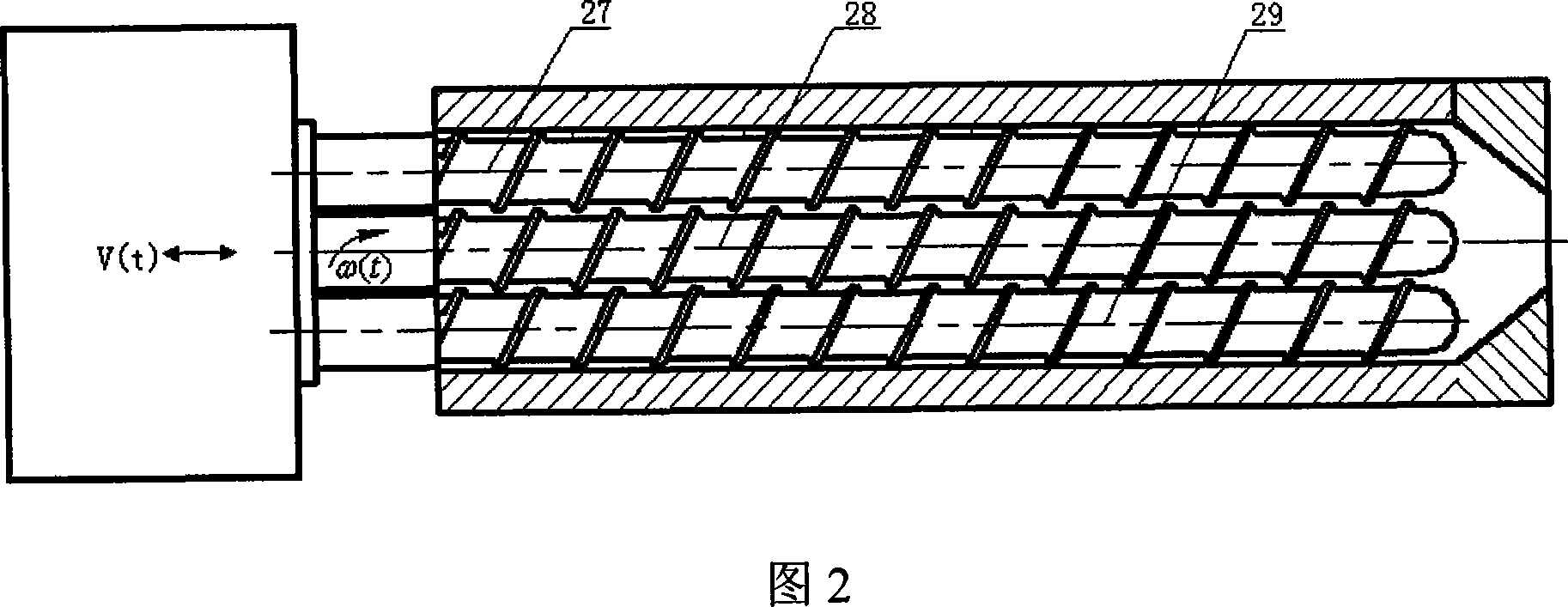

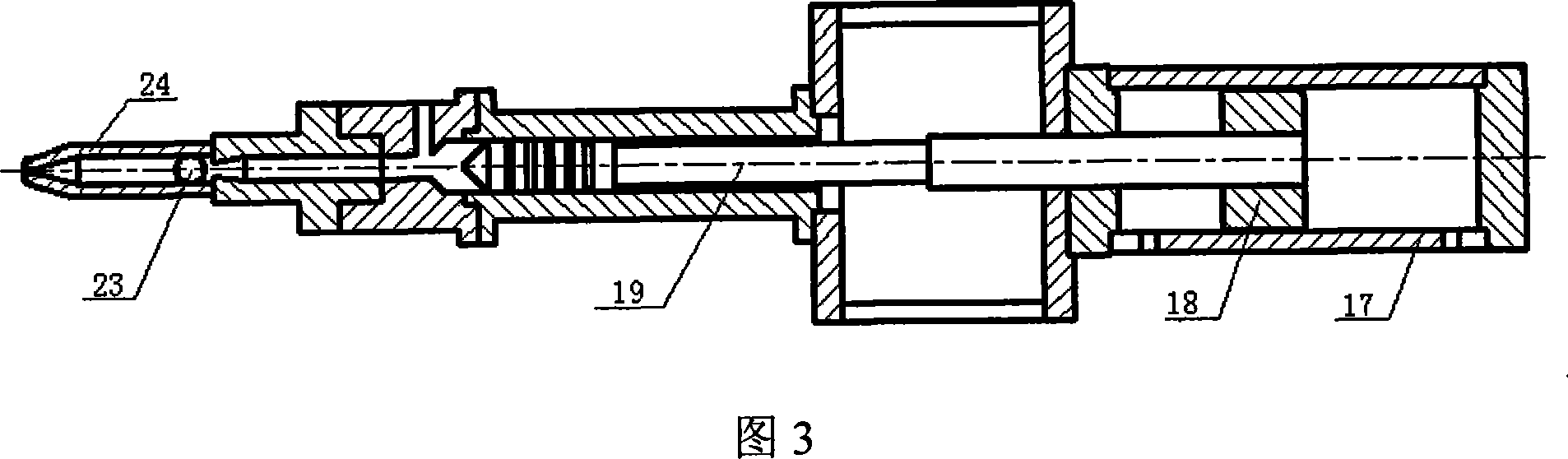

[0036] As shown in Figure 1 and Figure 2, a pulse-type impact-strengthened online compounding injection molding equipment is mainly composed of a pulse-type impact-strengthened three-screw extrusion device, a pulse-type shock-strengthened buffer storage barrel, and a pulse-type shock-strengthened plunger type The injection device constitutes. The screw of the "one"-shaped three-screw plasticizing extrusion device is composed of the main screw 28, the auxiliary screw one 27 and the auxiliary screw two 29. The driving motor 1 passes through the transmission shaft 2, the variable speed and power distributor 3, and the vibration excitation device 38 is connected to the main screw 28, and the sub-screw one 27 and the sub-screw two 29 are respectively located on both si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com