Nitrogen-doped graphene/tin oxide nano composite material and preparation method thereof

A nitrogen-doped graphene and nanocomposite material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of poor bonding between nanoparticle crystallinity and graphene, small contact area between negative electrode material and electrolyte, and negative electrode material. problems such as low electrical conductivity, to achieve the effects of controllable morphology, excellent electrochemical lithium storage performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

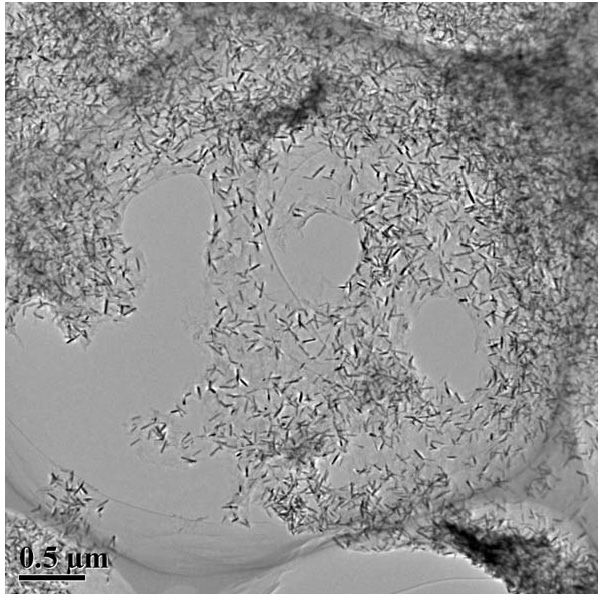

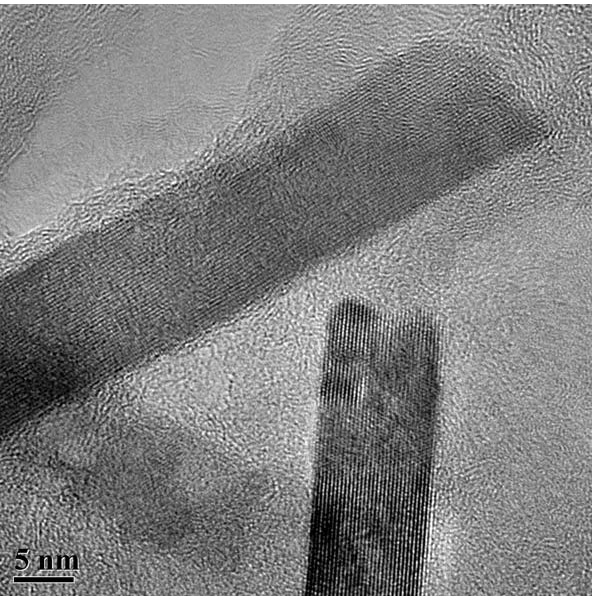

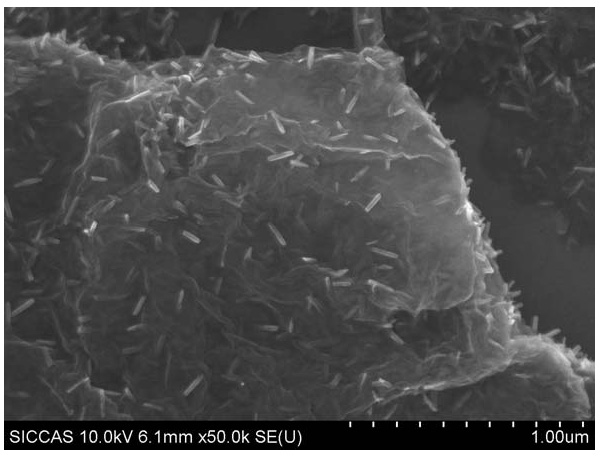

[0052] Dissolve tin chloride in 80 mL, 1 mg / mL graphene oxide sol, add 2.0 mL hydrochloric acid, and stir well to make the concentration of tin chloride aqueous solution 1.0 g / L. Then, the uniformly stirred mixed colloidal solution was transferred to a 100 mL hydrothermal reaction kettle, hydrothermally reacted at 120 °C for 24 h, cooled to room temperature naturally, washed with water and ethanol several times, and dried overnight at 60 °C. The diameter of tin oxide nanocrystals in the obtained graphene nanocomposites is 10 nm to 20 nm, and the length is 100 nm to 200 nm; the loading capacity of nanocrystals on the surface of graphene is 44%. The TEM figure of the obtained product is as attached Figure 1-3 Shown; The TG-DTA of the obtained product is as attached Figure 4 shown. The as-prepared graphene / tin oxide nanocomposites were used as anode materials for lithium-ion batteries at 100 and 200 mA g -1 The capacities were maintained at 710 and 575 mAh g after 50 cycles a...

Embodiment 2

[0054] Dissolve tin chloride in 80 mL, 1 mg / mL graphene oxide sol, add urea and 2.0 mL hydrochloric acid, and stir well, so that the aqueous solutions of tin chloride and urea have concentrations of 2.5 g / L and 0.5 mol / L. Then, the uniformly stirred mixed colloidal solution was transferred to a 100 mL hydrothermal reaction kettle, hydrothermally reacted at 120 °C for 24 h, cooled to room temperature naturally, washed with water and ethanol several times, and dried overnight at 60 °C. The diameter of tin oxide nanocrystals in the obtained graphene nanocomposite material is 2 nm to 6 nm, the length is 10 nm to 30 nm, and the loading capacity of nanocrystals on the surface of graphene is 65%. The TEM figure of the obtained product is as attached Image 6 shown. XPS analysis showed that nearly 5.8% of N elements were doped into the graphene / tin oxide nanocomposites.

Embodiment 3

[0056] Dissolve tin chloride in 80 mL, 0.5 mg / mL graphene oxide sol, add urea and 2.0 mL hydrochloric acid, and stir well, so that the concentrations of tin chloride and urea in aqueous solution are 5.0 g / L and 0.5 mol / mL, respectively. L. . Then, the uniformly stirred mixed colloid solution was transferred to a 100 mL hydrothermal reaction kettle, hydrothermally reacted at 90 °C for 24 h, cooled to room temperature naturally, washed with water and ethanol several times, and dried overnight at 60 °C. The diameter of tin oxide nanocrystals in the obtained graphene nanocomposite material is 2 nm to 5 nm, the length is 10 nm to 20 nm, and the loading capacity of nanocrystals on the surface of graphene is 52.5%. The TEM figure of the obtained product is as attached Figure 7 shown. XPS analysis showed that nearly 2.8% of N elements were doped into the graphene / tin oxide nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com