Method for composite electromagnetic continuous-casting high-oriented ultra-fine grained materials

A metal material and composite electromagnetic technology, applied in the field of metal casting technology, can solve the problems of high cost, high technical requirements, unsatisfactory transverse mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

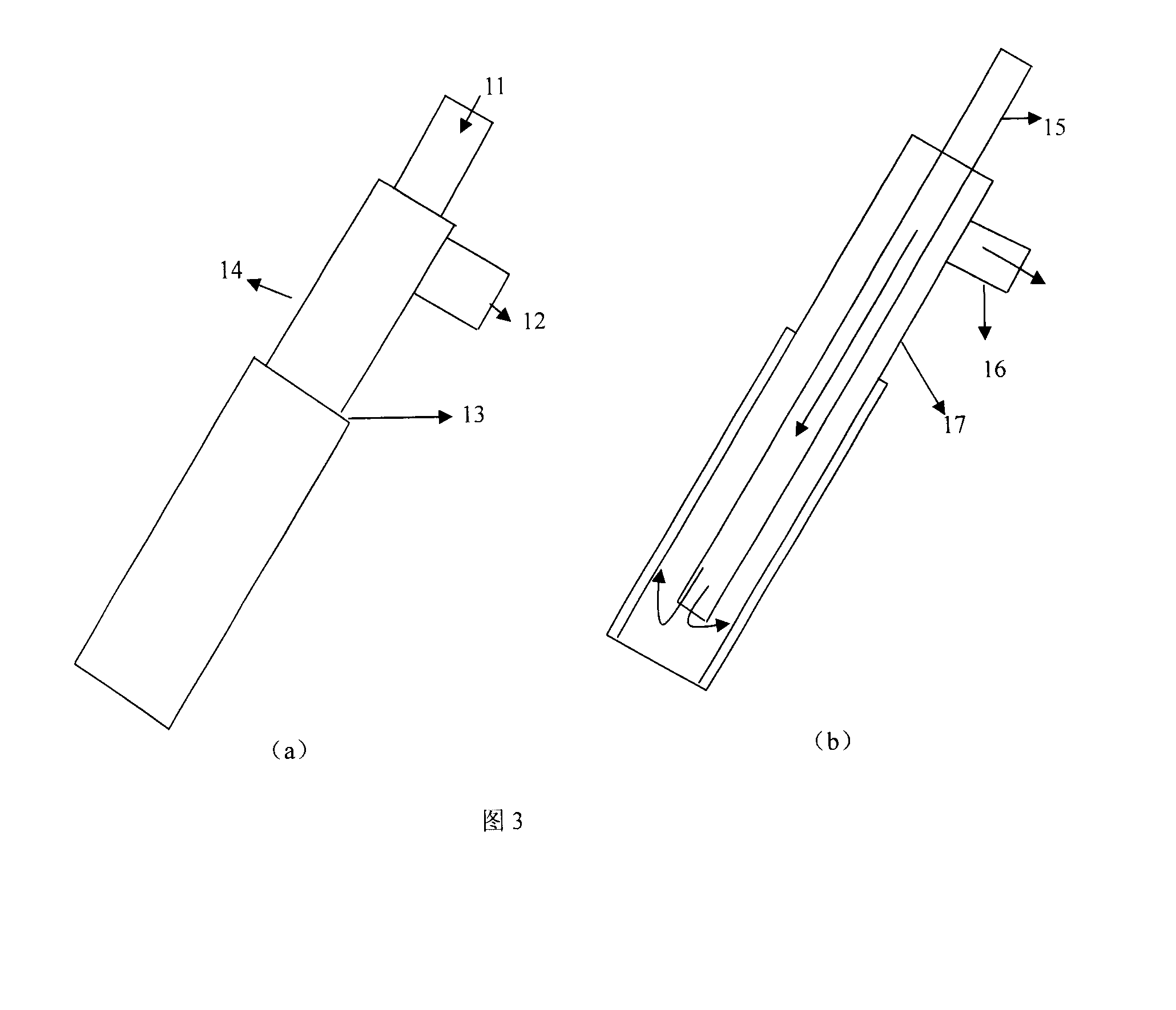

[0024] As shown in Figure 1, the device in this embodiment is mainly a crystallizer device, which includes: AC power supply device 1, self-cooling electrode 2, crystallizer cooling water jacket 3, water jacket inlet pipe 4, water jacket outlet Tube 5, DC induction coil 6, secondary cooling water nozzle 7, billet 8, dummy rod 9 and vibrating device 10; it is characterized in that a pair of self-cooling electrodes 2 are inserted and installed on the upper part of the metal melt in the crystallizer container , the electrode 2 is connected to the AC power supply device 1; a crystallizer cooling water jacket 3 arranged symmetrically on the left and right is arranged outside the crystallizer container, and the cooling water jacket 3 is provided with a water jacket water inlet pipe 4 and a water jacket outlet pipe 5; On the side, that is, in the middle cavity of the mold cooling water jacket 3, a DC induction coil 6 capable of generating a static magnetic field is isolated; A seconda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com