Ethylene tar resin granulation process and granulator

A ethylene tar and granulator technology, applied in the field of resin production, can solve the problems of inaccurate measurement of ethylene tar resin, increased cost of ethylene tar resin products, waste of manpower, material resources and time, etc., to achieve convenient packaging and transportation, The effect of reducing production costs and reducing heat energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

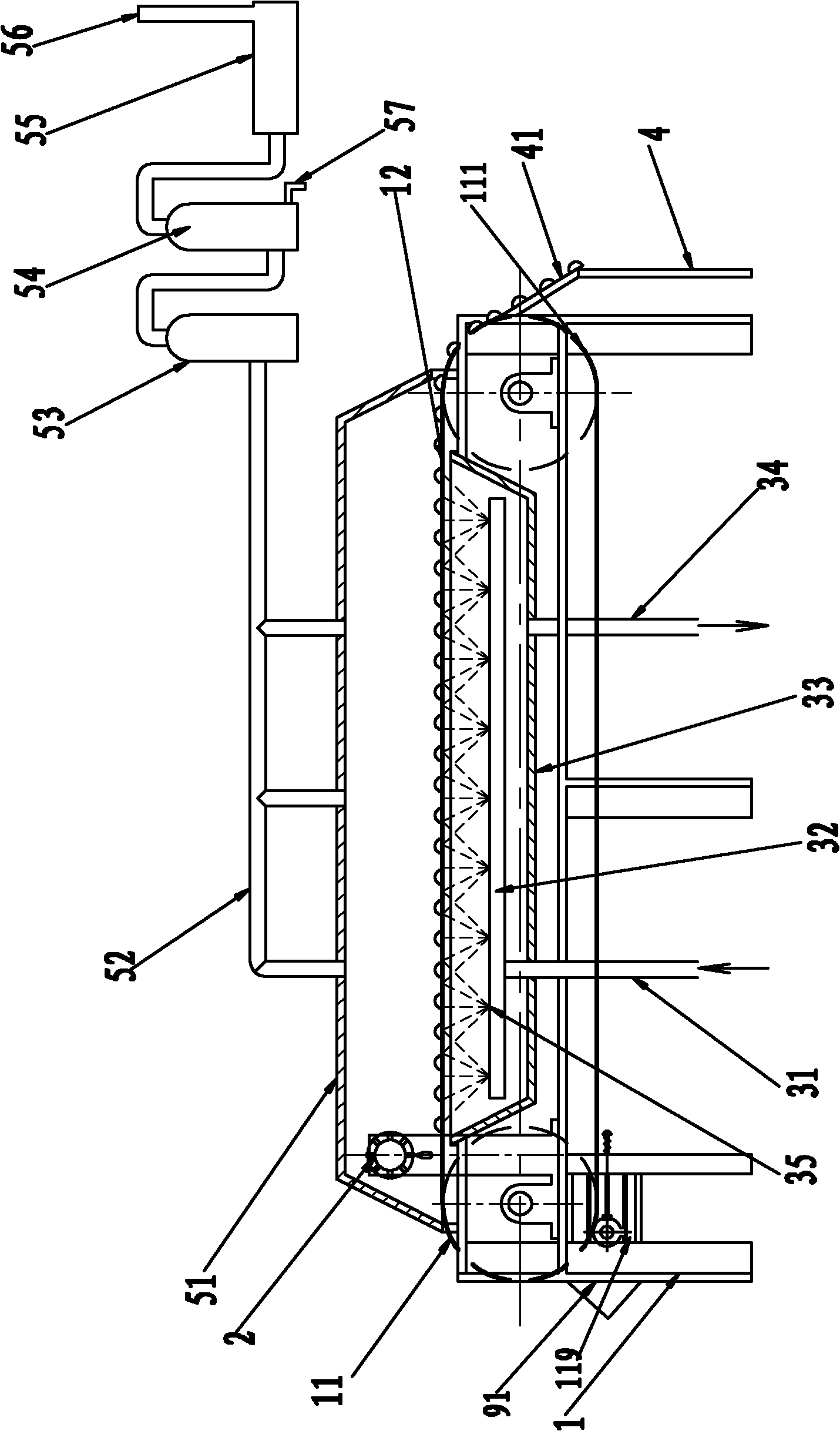

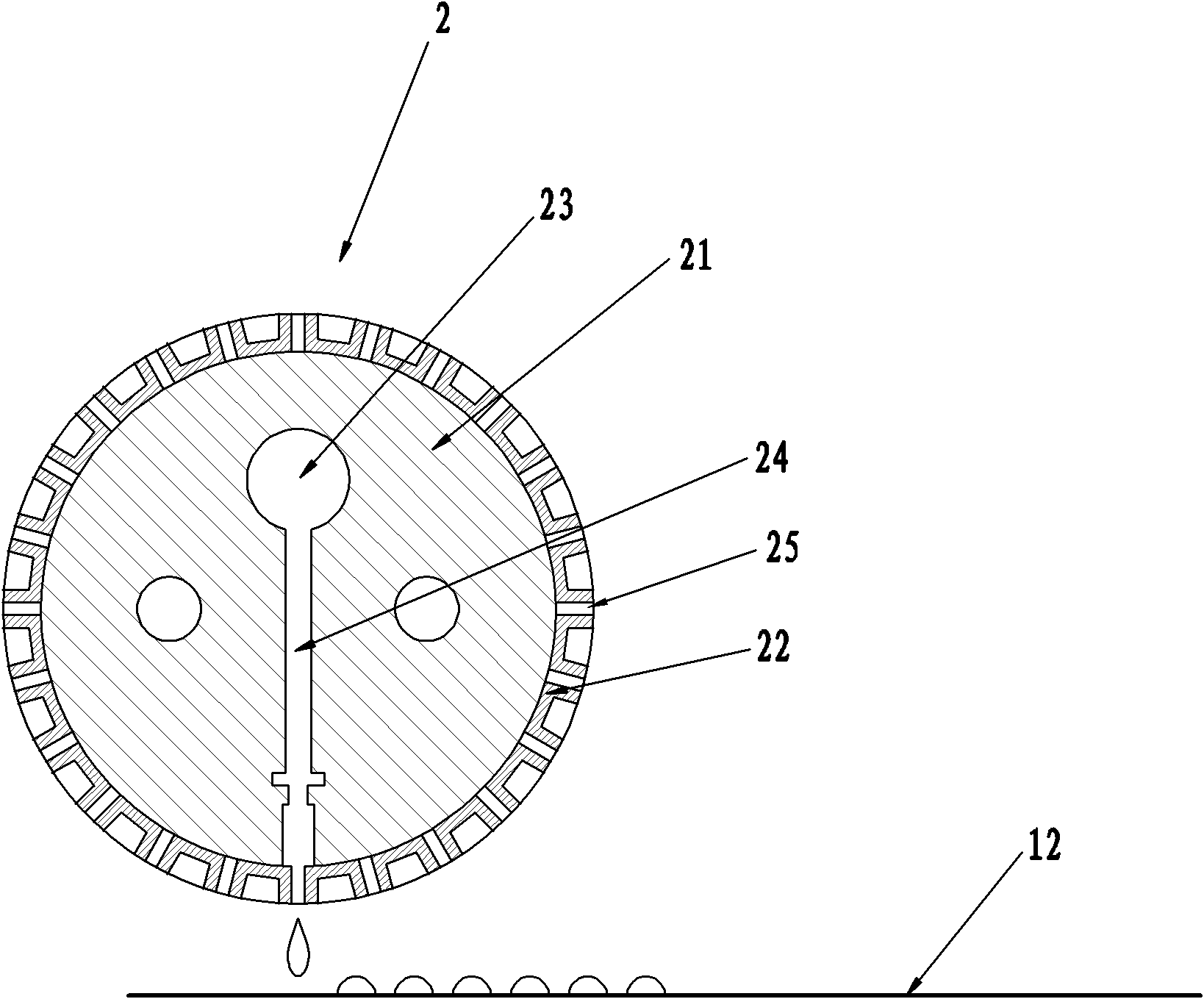

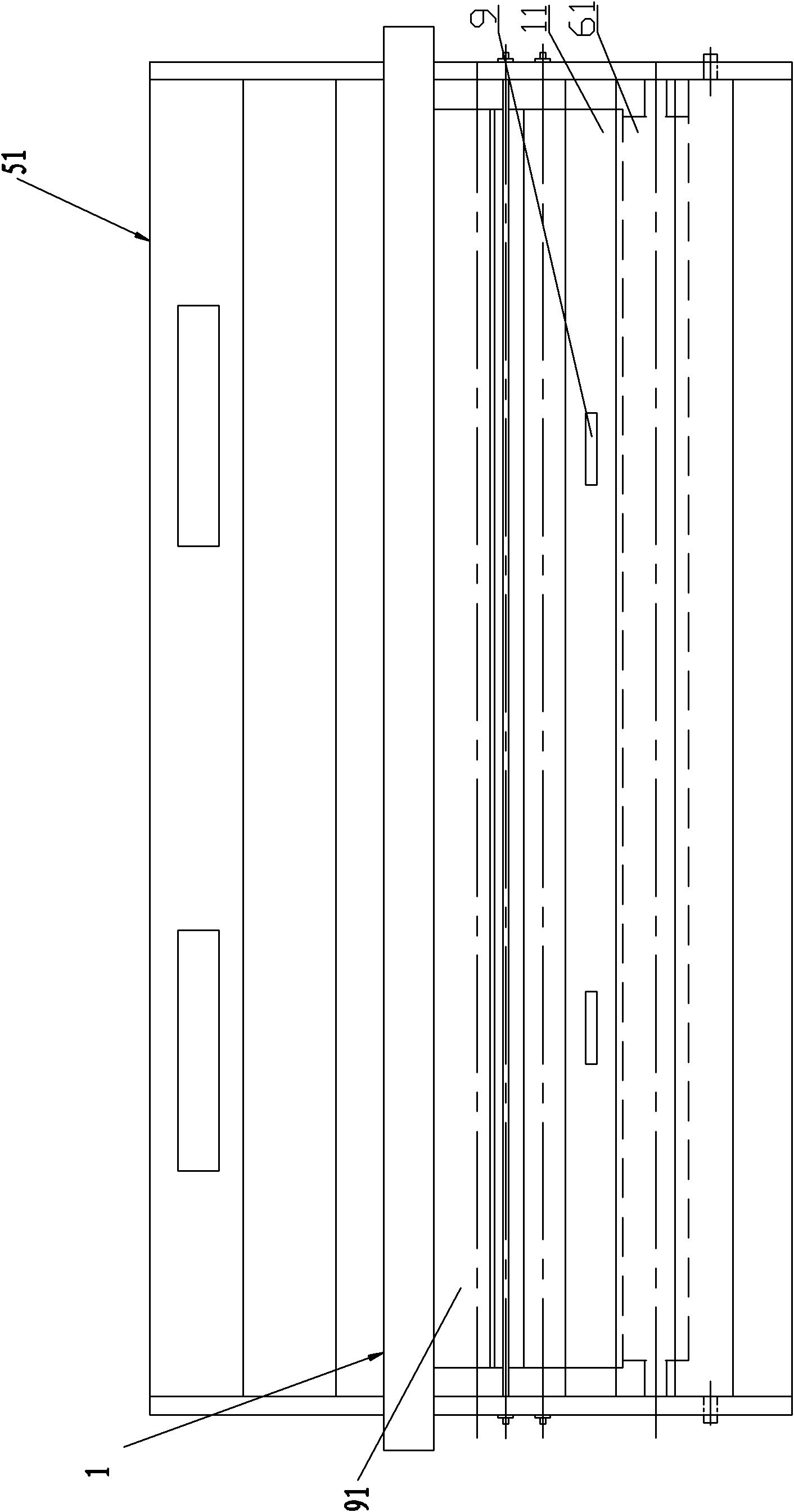

Method used

Image

Examples

Embodiment 1

[0040] (1) 8 tons of ethylene tar resin raw materials are pumped into the stripping tower kettle through a heavy oil pump, then 24 kg of initiator is added, the stripping tower kettle is heated, and the stripping tower vacuum unit is turned on to evacuate at the same time, so that the stripping tower can be stripped during the reaction. The temperature in the tower kettle is 180°C, the temperature at the top of the tower is 140°C, and the pressure is 0KPa. After the steam rising from the top of the stripping tower is cooled by the condenser at the top of the stripping tower, all the liquid phase enters the fuel oil receiving tank, and the liquid ethylene obtained by the reaction is The tar resin is located in the stripper kettle and reacted for 2 hours. After the reaction, turn off the vacuum unit to restore the pressure in the stripper kettle to normal pressure, and pass the ethylene tar resin into the resin through the discharge pipe at the bottom of the stripper kettle. In t...

Embodiment 2

[0044] What is different from embodiment 1 is step (1) and step (2), and step (3) is identical with embodiment 1.

[0045] (1) 18 tons of ethylene tar resin raw materials are pumped into the stripping tower kettle through a heavy oil pump, then 90 kg of initiator is added, the stripping tower kettle is heated, and the stripping tower vacuum unit is turned on to evacuate at the same time, so that the stripping tower can be stripped during the reaction. The temperature in the tower kettle is 200°C, the temperature at the top of the tower is 160°C, and the pressure is -30KPa. After the steam rising from the top of the stripping tower is cooled by the condenser at the top of the stripping tower, all the liquid phase enters the fuel oil receiving tank, and the liquid phase obtained by the reaction is The ethylene tar resin is located in the stripping tower kettle and reacted for 4 hours. After the reaction, turn off the vacuum unit to restore the pressure in the stripping tower kett...

Embodiment 3

[0048] What is different from embodiment 1 is step (1) and step (2), and step (3) is identical with embodiment 1.

[0049] (1) 10 tons of ethylene tar resin raw materials are pumped into the stripping tower still through the heavy oil pump, then add 80 kilograms of initiators, and heat the stripping tower still so that the temperature in the stripping tower still is 230 ° C in the reaction process. The top temperature is 180°C, the pressure is -60KPa, react for 7 hours to obtain ethylene tar resin, and pass the ethylene tar resin into the resin receiving tank through the discharge pipe at the bottom of the stripping column; the temperature of the ethylene tar resin obtained by polymerization is about is 225°C;

[0050] (2) Pass the cooled high temperature resistant heat transfer oil into the cooling coil in the resin receiving tank, and cool the ethylene tar resin in the resin receiving tank to a temperature of 156° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com