Method for laying ultra long cable

A cable, ultra-long technology, applied in the field of laying ultra-long cables, can solve the problems of scratching the main insulation layer of power cables, mixing into the main insulation layer of power cables, changing the shape of the nozzle, etc., to achieve good current skin effect, improve load flow, the effect of eliminating the limitation of towing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below.

[0039] As shown in the figure, the concrete steps of the present invention are:

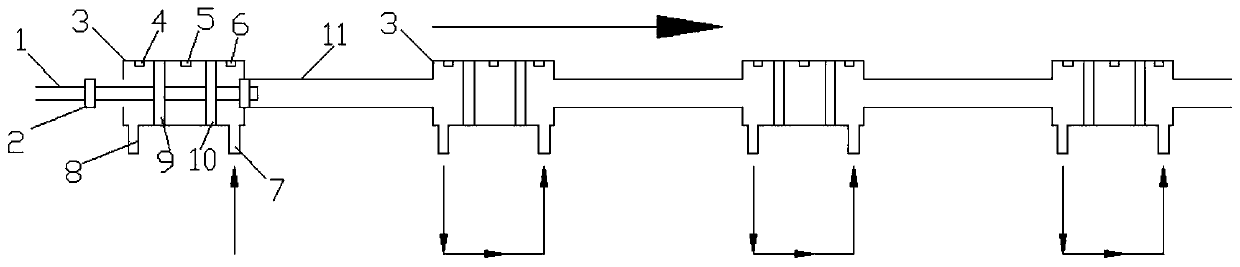

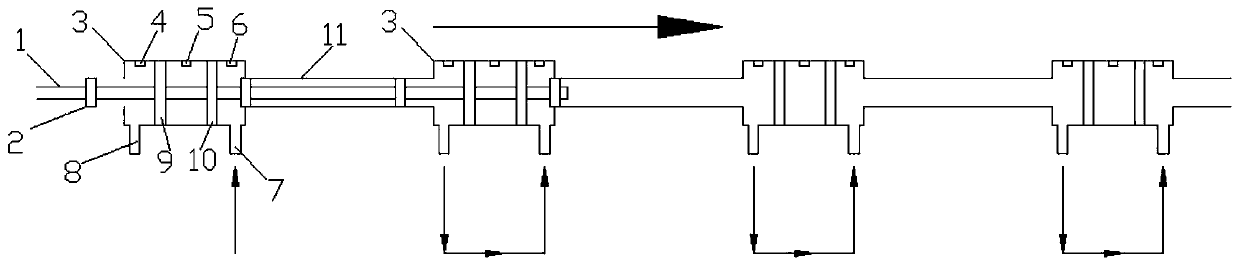

[0040] A. Pre-plan the laying path of the cable, set up multiple cable channels 11 of cable protection tube type on the laying path as required, and evenly distribute multiple hydraulic drive devices 3 on the cable channel 11, and the cable channels 11 and hydraulic drive devices 3 alternately End-to-end connection, so that the starting point and the end point of the laying are connected;

[0041] The hydraulic drive device 3 includes a housing, a position detection device I4, a variable diameter sealing device I9, a position detection device II5, a variable diameter sealing device II10 and a position detection device III6; the variable diameter sealing device I9 and the variable diameter sealing device II10 are arranged in sequence In the casing, the casing is divided into space I, space II and space III from near to far from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com